wire reinforcement

Latest articles

wire reinforcement

Post time: 04-08-22...

wire reinforcement 【wire reinforcement】

Read Morewire reinforcement

...

wire reinforcement 【wire reinforcement】

Read More

wire reinforcementThe formation process of hot dip galvanized layer is between the iron matrix and the outside of the pure zinc layer, the formation of iron-zinc alloy process, the workpiece surface in hot dip plating when the formation of iron-zinc alloy layer, so that the iron and pure zinc layer is well combined. The process of large roll galvanized wire can be simply described as: when the iron workpiece is immersed in the molten zinc liquid, the first zinc and α-iron (body-centered) solid melt is formed on the interface. This is a crystal formed by the matrix metal iron dissolved with zinc atoms in the solid state. The two metal atoms are fused with each other, and the attraction between the atoms is relatively small.

...

wire reinforcement 【wire reinforcement】

Read More2.0*2.0mm means that the two strands are 2.0mm silk, and the spines wrapped around the strands are also 2.0mm silk;

wire reinforcement...

wire reinforcement 【wire reinforcement】

Read Morewire reinforcement

...

wire reinforcement 【wire reinforcement】

Read More

wire reinforcement

Post time: 27-05-22...

wire reinforcement 【wire reinforcement】

Read More

wire reinforcementBarbed wire production of general selection of low carbon iron wire, after fine and accurate active welding equipment processing, the selection of galvanized process surface treatment. After the completion of the product, the net surface is smooth and regular, good integrity, strong consolidation, even if part of the trade-off or under pressure will not appear lax phenomenon.

...

wire reinforcement 【wire reinforcement】

Read More

wire reinforcementThe invention technology is used to put zinc block into the plating aid pool regularly, so that the bivalent iron in the plating aid becomes trivalent iron, and plays an important measure to stabilize the PH value within a numerical range, and also facilitate the filter filter out the trivalent iron ions in the plating aid; Ferric ion is controlled between 0.3 and 1.0g/L; When hydrogen is not released in the plating aid, the zinc block is continued. It is an effective measure to reduce zinc slag, improve the fluidity of zinc liquid and reduce the thickness of zinc layer to play the role of plating aid filter.

...

wire reinforcement 【wire reinforcement】

Read Morewire reinforcement

...

wire reinforcement 【wire reinforcement】

Read MoreAlthough the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank. Zinc is a silver-white metal, brittle at room temperature, soluble in acid and alkali, known as amphoteric metal. Pure zinc is more stable in dry air. In humid air or small water containing carbon dioxide and oxygen, the surface of large rolls of galvanized wire will generate a layer of basic zinc carbonate based thin film layer, which can delay the corrosion rate of zinc layer.

wire reinforcement...

wire reinforcement 【wire reinforcement】

Read More

Popular articles

Post time: 13-07-22- Using the patented technology of the invention, regularly put zinc block into the plating aid pool, so that the bivalent iron in the plating aid into trivalent iron, and play a stable PH value in a numerical range of an important measure, but also easy to filter out the trivalent iron ions in the plating aid; Ferric ion is controlled between 0.3 and 1.0g/L; When hydrogen is not released in the plating aid, the zinc block is continued. It is an effective measure to reduce zinc slag, improve the fluidity of zinc liquid and reduce the thickness of zinc layer to play the role of plating aid filter.

The service life of the original galvanized iron welding mesh is very limited. Generally, good iron railings can only be used for about 2 years, and then renovated until the service life, which is not only time-consuming but also has safety risks. After the appearance of zinc-steel railings, the service life has been increased to a great extent in the post-processing. Generally, it can be used for at least 20 years. To improve the service life of zinc steel railings, we first have a brief understanding of the product characteristics of railings. Then from the maintenance aspect, it is necessary to maintain. Maintenance method of electric welding mesh:

- The common barbed rope produced by the manufacturer is the 14*14 type of barbed rope product. Since the warp wire used is the same as the wire diameter of the barbed rope, it is easier to calculate the length and weight. Usually each kilogram of barbed rope can reach about 10 meters of service length. The length of each kilogram of raw material is about 35 meters. Since 35 meters of raw material wire diameter can produce 10 lengths of barbed rope cost.

Stainless steel barbed rope in the way of corrosion is not very, because the surface is not treated but rely on its own raw materials for corrosion resistance, so there will be no chemical reaction. After a long time of use, it will not rust like the corrosion layer on the surface of hot dip galvanized barbed rope, because the internal material of stainless steel barbed rope is the same as the material on the surface. The most obvious difference in a short time is the cross section of this piece, hot dip galvanized barbed wire because of surface anticorrosion treatment, so there will be rust in the cross section of this piece, and stainless steel barbed wire because the internal raw materials and surface raw materials are consistent, so there is no such situation.

Latest articles

-

Although galvanized hook mesh is outstanding because of its surface, this does not mean that this hook mesh product is not useful. From the point of view of people’s use of it, this hook mesh products through a surface of galvanized treatment, whether it is wind and sun, or man-made inadvertent damage, will not bring a little harm to it, so the more comprehensive use of galvanized hook mesh products will then be widely used in several fields.

-

Galvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

-

The wide application of galvanized wire has brought great convenience to people’s production and life, but the production process of iron wire is not to be underestimated. In industrial production, the production process of galvanized wire should be strictly controlled to ensure the quality of galvanized wire.

-

Post time: 05-09-22 -

-

Links

china tr 92 titanium dioxide. The country has implemented strict regulations on emissions and waste disposal, which has encouraged the adoption of more sustainable production methods and technologies. This has not only benefited the environment but also enhanced the competitiveness of Chinese TiO2 producers in the global market.

china tr 92 titanium dioxide. The country has implemented strict regulations on emissions and waste disposal, which has encouraged the adoption of more sustainable production methods and technologies. This has not only benefited the environment but also enhanced the competitiveness of Chinese TiO2 producers in the global market.No. EFSA’s role was limited to evaluating the risks linked to titanium dioxide as a food additive. This included an assessment of relevant scientific information on TiO2, its potential toxicity, and estimates of human dietary exposure. Any legislative or regulatory decisions on the authorisations of food additives are the responsibility of the risk managers (i.e. European Commission and Member States).

As the demand for high-quality paints continues to grow, manufacturers in the paint industry can rely on Lomon's R996 grade titanium dioxide to meet their needs. With its exceptional performance characteristics and consistent quality, this product is a trusted choice for paint manufacturers looking to create durable, vibrant, and long-lasting finishes for a wide range of applications.

Since then, there has been a few animal studies suggesting titanium dioxide is connected to cancer. A 2017 study in Scientific Reports, for instance, found that rats with titanium dioxide in their diet had impaired immune systems, which could contribute to autoimmune diseases and colorectal cancer.

The effects of TiO2 NPs in plants

In a study published in the journal Environmental Toxicology and Pharmacology in 2020, researchers examined the effects of food additives titanium dioxide and silica on the intestinal tract by grouping and feeding mice three different food-grade particles — micro-TiO2, nano-TiO2, and nano-SiO2. With all three groups, researchers observed changes in the gut microbiota, particularly mucus-associated bacteria. Furthermore, all three groups experienced inflammatory damage to the intestine, but the nano-TiO2 displayed the most pronounced changes. The researchers wrote: “Our results suggest that the toxic effects on the intestine were due to reduced intestinal mucus barrier function and an increase in metabolite lipopolysaccharides which activated the expression of inflammatory factors downstream. In mice exposed to nano-TiO2, the intestinal PKC/TLR4/NF-κB signaling pathway was activated. These findings will raise awareness of toxicities associated with the use of food-grade TiO2 and SiO2.”

Characteristics of Common White Pigments

Stability and darkening[edit]

Food safety experts in the European Union (EU) have recently updated their safety assessment of TiO2 as a food additive. In Europe, TiO2 is referred to as E171, in accordance with European labelling requirements for food additives. The EU expert panel took into account toxicity studies of TiO2 nanoparticles, which to this point had not been considered relevant to the safety assessment of TiO2 as a food additive.

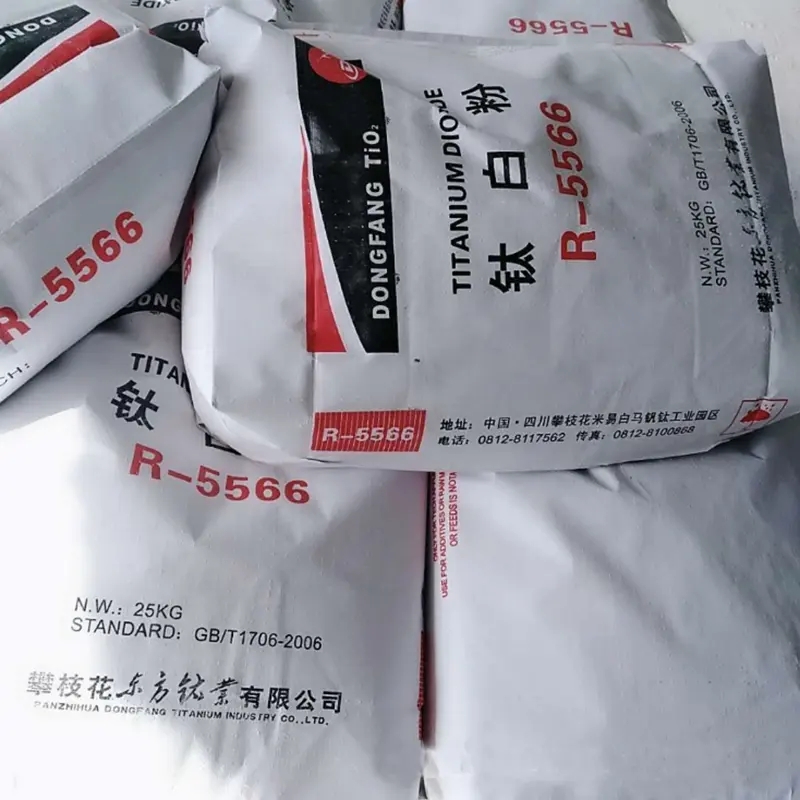

High Scattering Power TiO2 DongFang R5566

This article discusses the discovery of phosphorescent lithopone on watercolor drawings by American artist John La Farge dated between 1890 and 1905 and the history of lithopone in the pigment industry in the late 19th and early 20th centuries. Despite having many desirable qualities for use in white watercolor or oil paints, the development of lithopone as an artists’ pigment was hampered by its tendency to darken in sunlight. Its availability to, and adoption by, artists remain unclear, as colormen's trade catalogs were generally not explicit in describing white pigments as containing lithopone. Further, lithopone may be mistaken for lead white during visual examination and its short-lived phosphorescence can be easily missed by the uninformed observer. Phosphorescent lithopone has been documented on only one other work-to-date: a watercolor by Van Gogh. In addition to the history of lithopone's manufacture, the article details the mechanism for its phosphorescence and its identification aided by Raman spectroscopy and spectrofluorimetry.

Lithopone 30% is a perfect alternative to titanium dioxide in all natural and synthetic pigmented elastomers, as it is non-abrasive and extremely acid resistant.

Zns 28-30% Chemical Provide Lithopone Pigments Low Price

best rutile titanium dioxide tio2 supplier.

When we purchase lithopone, we must pay attention to its ratio. This can be seen to some extent from the appearance. Basically, we can see that good products are very delicate. , and the color is also very uniform, a kind of shiny white, while inferior lithopone has uneven particles and wrong luster.

better

Tint reducing power, compared with standard samples