HPMC is a water-soluble polymer derived from cellulose, a natural polymer obtained from plant cell walls. It is created through a chemical process that modifies cellulose, providing it with specific properties such as increased water retention, improved adhesive qualities, and enhanced workability. These characteristics make HPMC a valuable additive in various applications, especially in tile adhesive formulations.

In the food industry, hydroxypropyl methylcellulose is recognized for its ability to act as a thickener, stabilizer, and emulsifier. It contributes to the texture of numerous products, including sauces, dressings, dairy items, and baked goods. By improving the consistency of food items, HPMC enhances consumer satisfaction with sensory attributes.

3. Esterification The alkali cellulose is then subjected to a reaction with methyl chloride and propylene oxide. This process introduces hydroxypropyl and methyl groups to the cellulose structure, resulting in hydroxypropyl methyl cellulose. The ratio of the two groups can be adjusted to achieve the desired properties of HPMC.

1. Pharmaceuticals HEC is often used in the formulation of drugs, especially in creating controlled-release matrices. Its ability to swell in an aqueous environment helps in the sustained release of active pharmaceutical ingredients.

Conclusion

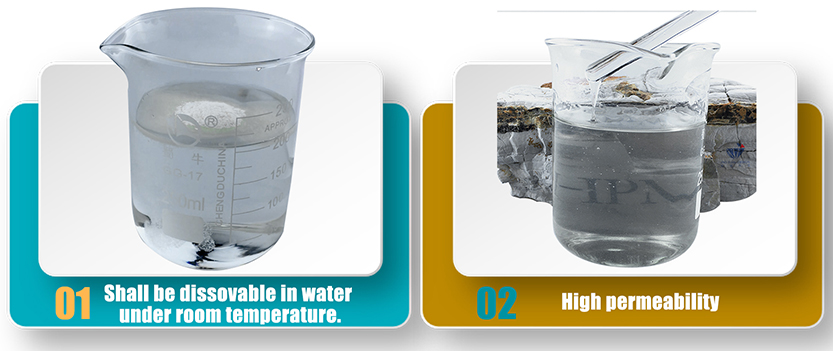

HPMC is well-known for its ability to dissolve in cold water, a characteristic that is particularly beneficial for many applications. Unlike some polymers that require heat for solubilization, HPMC can hydrate and disperse effectively at room temperature. This property allows for ease of formulation in various products, as energy-intensive processes such as heating are not necessary.

Role in Cosmetics and Personal Care

HPMC is a semi-synthetic polymer derived from cellulose, which is a natural polymer obtained from plant cell walls. The modification process involves the substitution of hydroxyl groups in cellulose with hydroxypropyl and methyl groups, resulting in a versatile compound that offers numerous functional benefits. Due to its inertness and compatibility with a broad array of active pharmaceutical ingredients (APIs), HPMC is commonly used in drug formulations, particularly in oral solid dosage forms like tablets and capsules.

HPMC Solubility in Water An Overview

The other option we are examining today is HPMC “vegetarian” capsules. As their name indicates, these capsules are manufactured from 100% plant-based materials, including hydroxypropyl methylcellulose. HPMC capsules do not contain animal-derived ingredients; they were developed about 30 years ago during the search for an equally-efficient alternative to hard gelatin capsules. Since their introduction, HPMC capsules have acquired a market share in the global empty capsule industry thanks to their natural origin, an increased demand for vegetarian products, and the capsules’ excellent stability with a variety of API's.

Hydroxyethylcellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer made from plant cell walls. This multifunctional compound has garnered significant attention across various industries, particularly in pharmaceuticals, cosmetics, and food production. Its ability to gel, thicken, and stabilize makes it an indispensable ingredient in many formulations. As the demand for HEC continues to grow, a myriad of suppliers now offer hydroxyethylcellulose for sale, catering to diverse applications.

While redispersible polymer powders offer numerous advantages, it is essential to understand that their performance is highly dependent on various factors, including the type of polymer used, the presence of additives, and the formulation of the end product. Therefore, it is crucial to tailor the use of RDPs to specific applications to maximize their benefits.

Moreover, HEC is known for its excellent film-forming ability, emulsification properties, and compatibility with other substances. It is odorless, tasteless, and generally considered non-toxic, making it suitable for use in products that require direct contact with skin, such as cosmetics and pharmaceuticals. Due to its amphiphilic nature, HEC can interact with both hydrophilic and hydrophobic compounds, expanding its utility across different domains.

In construction, HPMC is employed as an additive in cement and gypsum plaster formulations. Its water-soluble nature allows it to improve workability, increase adhesion, and enhance durability of the mixtures. By controlling the rate of water retention and evaporation, HPMC enables better application and performance of construction materials, which is vital for structural integrity and longevity.

The chemical formula of hydroxyethyl cellulose is (C2H6O2)n, where n indicates the degree of polymerization and can vary widely depending on the manufacturing process. HEC is identified by the CAS number 9004-62-0. This unique identifier helps researchers, manufacturers, and regulatory bodies to catalog and reference the compound accurately.

Construction and Cosmetic Industries

4: Environmental concerns:

EPA – Clean Air Act Amendments – Hazardous Air Pollutants includes Methyl Chlorides and Propylene oxide, two chemicals used in production of HPMC.(FR67:112: 40044) June 11, 2002.

Several factors influence the glass transition temperature of HPMC. These include the degree of substitution, molecular weight, and the presence of additives. The degree of substitution refers to the extent to which the hydroxyl groups in cellulose are replaced with hydroxypropyl and methyl groups. Higher degrees of substitution typically lead to a lower Tg, as the added functional groups increase the flexibility of the polymer chains.

The multifaceted benefits and applications of hydroxypropyl methylcellulose make it an invaluable additive across diverse industries. From its role in pharmaceuticals and food production to its use in cosmetics and construction, HPMC showcases the power of cellulose derivatives in enhancing product performance. As research and technology continue to advance, the potential applications of HPMC are likely to expand, paving the way for innovative uses that further harness its versatile properties. As such, HPMC is not only a product of the past but also a cornerstone for future advancements in various fields.

There are a few blogs and sites pushing scare stories regarding the heavy metals found in HPMC. The heavy metals present in our HPMC are tested and certified at a level of under 10 parts per million. This is significantly below the threshold of what might be considered unsafe for human consumption. Again, it's worth noting that heavy metals are all around us and when consumed in small doses, are perfectly safe - our bodies naturally filter them out. They are found in fish, greens, brown rice and more. To clarify, we are not saying that the consumption of heavy metals is a particularly good thing, just that any form of panic or hysteria regarding the consumption of minuscule amounts of them is not helpful. For example - there is more mercury in fresh tuna than there is in HPMC. That is the very same tuna that is prized in Japanese cuisine - a country which had the second highest life expectancy in the world in 2018.

In the pharmaceutical industry, HPMC serves multiple important functions. It is commonly used as a binder in tablet formulations, ensuring uniformity in the distribution of active ingredients. Additionally, HPMC is utilized as an excipient, which is an inert substance that allows the drug to be shaped into tablets or capsules. Its ability to swell in water and form gels makes it an ideal candidate for controlled release formulations, enabling a gradual release of medication over time, which enhances the drug's therapeutic effects and improves patient compliance.

In conclusion, hydroxyethyl cellulose is a multifaceted polymer with a broad spectrum of applications across various sectors. Its ability to enhance formulations by providing thickening, stabilizing, and emulsifying properties makes it an indispensable ingredient in numerous products. As industries increasingly prioritize sustainability, the biodegradable nature of HEC positions it as an attractive alternative to more traditional synthetic polymers. With ongoing research and development, the potential applications of hydroxyethyl cellulose continue to expand, ensuring its relevance in the future of material science and formulation chemistry.

In the pharmaceutical sector, MHEC serves as a binder and controlled-release agent in tablets and capsules. Its ability to form gels and create films makes it an excellent choice for coatings, providing a protective barrier for active ingredients. Additionally, MHEC is utilized in drug formulations to enhance bioavailability, making it a vital component in the development of effective pharmaceuticals.

Hydroxypropyl Methylcellulose (HPMC) is a versatile, water-soluble polymer derived from cellulose, a natural biopolymer predominantly obtained from plant cell walls. Its unique properties make it an indispensable ingredient in various industries, including pharmaceuticals, food technology, cosmetics, and construction. This article explores HPMC’s attributes, applications, and significance in different sectors.

The incorporation of HPMC powder into various formulations brings numerous benefits. Its outstanding thickening ability allows for the creation of products with desirable viscosities without significantly altering the formulation's other characteristics. Additionally, HPMC is non-toxic and environmentally friendly, making it suitable for use in products targeted at sensitive populations, such as children and individuals with allergies.

Gelatin Capsules vs HPMC Capsules

- Versatility HEC’s multifunctional properties allow it to be used across diverse industries. Whether in cosmetics, pharmaceuticals, or construction, its adaptability makes it invaluable.

What is HPMC?

dispersible polymer powder. Additionally, dispersible polymer powders can also be used to create controlled-release formulations that provide a sustained release of the active ingredient over time.