electro galvanized nails

Latest articles

electro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read More

electro galvanized nailsCold galvanized wire refers to a process in which ordinary steel wire is treated by cold galvanized and a zinc layer is attached to its surface. Cold galvanized wire has the advantages of anti-corrosion and anti-wear, and is widely used in construction, machinery, automobile, electronics and other industries. The following will introduce the production process and flow of cold galvanized wire.

...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read MoreIn the corner area, the zinc layer is often thicker than other places, and has good toughness and abrasion resistance. And other coatings in this corner, often Z thin Z is not easy to construction, Z is easy to hurt, so often need to be maintained. Even if there’s a lot of mechanical damage or something. Causing a small layer of zinc to peel off, leaving the iron base exposed, the surrounding zinc layer will act as a sacrificial anode to protect the steel from erosion.

electro galvanized nails...

electro galvanized nails 【electro galvanized nails】

Read Moreelectro galvanized nails

...

electro galvanized nails 【electro galvanized nails】

Read MoreOrigin: Hebei

electro galvanized nails...

electro galvanized nails 【electro galvanized nails】

Read More

Popular articles

Some customers may not immediately use the blade barbed rope when they buy it for retail and some are temporarily not used for site construction. At this time, customers need to follow up the characteristics of the blade barbed rope for storage. Because they are afraid of the rain, so there is no need to say more, and the surface of the packaging is more afraid of the sun, so it is not recommended to prevent the outside of the blade thorn rope will lead to the woven bag become lost effect, resulting in the exposure of the internal blade thorn rope affect the later use.

- Different hot dip galvanizing process is divided into two categories of annealing outside the line and annealing in the line, hot dip galvanizing is in the hot melt zinc liquid immersion plating, production speed, thick but uneven coating, the market allows Z low thickness of 45 microns, Z high can reach more than 300 microns. It is dark in color, consumes more zinc metal, forms infiltration layer with base metal, and has good corrosion resistance. Hot dip galvanizing can be maintained for decades in outdoor environment.

- The galvanized requirements of the parts to be plated: the surface of the parts to be plated should be smooth, and there is no dirt that cannot be removed by pickling method. Such as paint, grease, cement, asphalt and excessive rotten harmful substances; All welds of welded components shall be sealed without air; Pipe fittings and containers must have exhaust and zinc inlet holes; The workpiece should be finished welded steel pipe without thread, if any thread should be protected.

Latest articles

-

-

Galvanized wire is immersed in heated molten zinc, the production speed is fast, the coating is thick but uneven. The thickness of 45 microns allowed by the market, the color is dark, the consumption of zinc metal is more, and the matrix metal is formed into an infiltration layer, and the corrosion resistance is good. The hot dip galvanizing can be maintained for decades in the outdoor environment.

-

-

-

-

Links

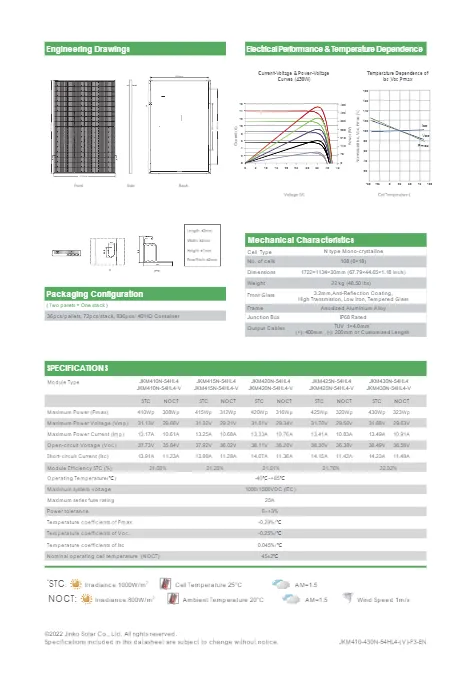

3. Installation Costs Labor costs can vary based on the complexity of the installation, roof type, and local labor rates. Professional installation is recommended to ensure the system is safe, efficient, and compliant with local regulations.

3 kilowatt solar panel price

1. Cost Savings One of the most significant advantages of on-grid solar systems is the potential for substantial savings on electricity bills. By using solar power during the day, homeowners can reduce their reliance on grid electricity, leading to lower energy costs. Additionally, net metering can provide financial credits for any excess energy sent back to the grid.

In conclusion, the dream of a 100% solar panel-utilized world is not just an idealistic vision; it is a tangible goal that is within reach. By embracing solar energy, we can combat climate change, enhance energy independence, and pave the way for a sustainable future. The commitment to maximizing solar power usage will require concerted efforts from individuals, businesses, and governments alike, but the rewards—both ecological and economic—are undeniably worth pursuing. As we stand on the brink of this energy revolution, the time to act is now. The sun may be our greatest ally in crafting a sustainable future, one solar panel at a time.

What is an Off-Grid Inverter?

2. Type of Panels Solar panels come in various types, including monocrystalline, polycrystalline, and thin-film panels. Monocrystalline panels are typically more efficient and have a higher cost, while polycrystalline panels offer a more economical option but may take up more space.

Conclusion

Factors Influencing Dimensions

Market Availability