coil of barbed wire

Latest articles

coil of barbed wireWith the improvement of people’s living standards, now many families are raising some small pets, these small pets need a stable nest, pet cage has become a more important choice of people, each pet habits and living habits will choose to adapt to the cage.

...

coil of barbed wire 【coil of barbed wire】

Read Morecoil of barbed wire

...

coil of barbed wire 【coil of barbed wire】

Read MoreGalvanized wire for welding is generally required to have a certain hardness, after acceptance of galvanized wire, feel is the first thing to do, in addition to the machine test, because the average user does not have testing equipment, on the machine trial is also a very inconvenient way to test. The diameter of electric galvanized wire is measured with a micrometer, and it is kept at about 0.02mm above and below the contract signing standard, with neat appearance, no leakage plating and no messy wire.

coil of barbed wire...

coil of barbed wire 【coil of barbed wire】

Read Morecoil of barbed wire

...

coil of barbed wire 【coil of barbed wire】

Read More

coil of barbed wire

Post time: 04-01-23...

coil of barbed wire 【coil of barbed wire】

Read More

coil of barbed wireDog cage mainly by welding, spraying, injection molding, surface treatment, electroplating dog cage is made of high quality steel wire, dog cages are with plastic and plastic surface treatment, electrophoresis, chrome plating, galvanized, imitation gold, etc., according to the customer request processing, respectively, also can be customized to sample, dog cage assembly of compact structure, neat and beautiful appearance, make folding and remove the cage is more convenient and quick, won’t take up too much space.

...

coil of barbed wire 【coil of barbed wire】

Read Morecoil of barbed wire

...

coil of barbed wire 【coil of barbed wire】

Read More

coil of barbed wireThe whole welding process of galvanized steel wire mesh does not need special technological methods, good weldability. However, in a few cases, the welding process will present difficulties: the converter steel produced by the old smelting method has high nitrogen content and high impurity content, resulting in high cold brittleness, added aging sensitivity, lower quality of welded joints, and poor weldability.

...

coil of barbed wire 【coil of barbed wire】

Read Morecoil of barbed wire

...

coil of barbed wire 【coil of barbed wire】

Read More

coil of barbed wireZinc pot workers should be determined to do duty and responsibility. Do not leave the post without leave, always observe the change of hot plating wire galvanized layer, and according to the analysis results, master the asbestos block gap friction, how long it takes to press, replace the pressing face; Adjust the working face; Until all four faces of the asbestos block are used up, maintenance workers can continue to use the asbestos block after repair when necessary to reduce the consumption of asbestos block.

...

coil of barbed wire 【coil of barbed wire】

Read More

Popular articles

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

The advantage of galvanized iron wire after annealing: after annealing increases the elongation of the iron wire. Makes the product softer and increases the range of application. After electric galvanizing hot dip galvanizing. Copper electroplating is widely used and screen production. Galvanized iron wire is a soft iron wire product processed by low carbon steel wire through cold drawing, heating, constant temperature, and even heat preservation. Generally, the quality of ordinary galvanized iron wire will be relatively soft, the softness is relatively balanced, and the color is consistent. It is mainly used in construction, mining, chemical industry and so on.

Latest articles

Links

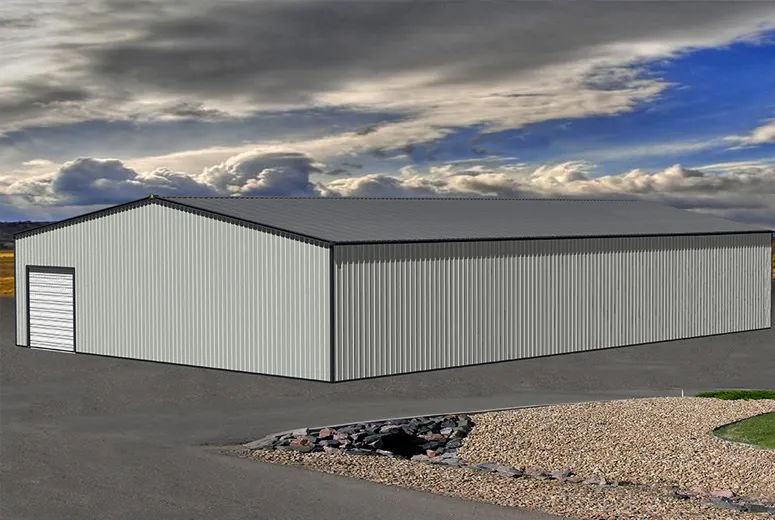

One of the standout advantages of steel portal frame warehouses is the speed of construction. The components are typically prefabricated off-site and then assembled on location. This process can significantly reduce construction time compared to conventional building methods. Faster construction not only minimizes labor costs but also enables businesses to occupy their facilities sooner, allowing them to begin operations without lengthy delays.

The Charm and Utility of a Narrow Metal Shed

Eco-Friendliness

The Rise of Modular Workshop Buildings

It’s important to consider the scalability of the layout. Plans should allow for easy expansion of zones or the addition of new equipment. This foresight can save time and resources in the long run, ensuring the workshop remains competitive in an ever-evolving industry.

Shed frames play a crucial role in the construction of garden sheds, storage units, and small workshops. Their structure not only determines the overall strength and durability of the shed but also affects its aesthetic appeal. This article will delve into the essentials of shed frames, discussing their types, materials, construction techniques, and design considerations.

Building a Steel Pole Barn with Living Quarters

In the ever-evolving field of agriculture, the efficiency of farm operations can significantly impact productivity and profitability. One crucial aspect often overlooked is the provision and maintenance of proper farm equipment buildings. These structures serve as the backbone of modern farming, ensuring that machinery and tools are housed, organized, and maintained effectively.

In addition to their practical benefits, red barn steel buildings are highly customizable. They come in various sizes and configurations, enabling owners to tailor the design to their specific needs. Whether it’s a spacious storage facility for hay, a workshop for equipment repair, or a cozy farm office, the options are virtually limitless. Many manufacturers offer a range of color choices and architectural features, allowing clients to create a unique structure that aligns with their vision.

red barn steel buildings

Red barn steel buildings have gained significant popularity over the past few years, emerging as a modern solution for various agricultural, commercial, and recreational needs. These structures combine classic aesthetics with durability and versatility, making them an ideal choice for farmers, business owners, and homeowners alike.

6. Market Trends

One of the primary benefits offered by industrial shed manufacturers is the ability to customize structures according to client needs. Different businesses have unique requirements based on their operations, whether they need a simple storage shed or a more complex manufacturing facility. Manufacturers work closely with clients to create tailored solutions that encapsulate their operational needs while also adhering to local building codes and safety regulations.

Where to Find Metal Workshop Buildings for Sale

The Cost of Steel Frame Barns An In-Depth Analysis

Exploring Metal Farm Sheds A Durable Solution for Agricultural Needs

Whether you require wide-open spaces or extensive lengths, steel structures provide the flexibility to accommodate your requirements seamlessly.

Effective cost management strategies can significantly enhance a steel workshop's profitability. Conducting thorough market research can help workshop owners understand pricing strategies in the industry. Estimating project costs accurately and maintaining a lean inventory can minimize excess costs.

Conclusion

The cost of prefabricated metal buildings can vary widely, generally ranging from $10 to $25 per square foot. For a standard building, this could translate to price tags between $5,000 and $50,000 or more, depending on the size, complexity, and customizations involved. It's essential to understand that this pricing usually covers the basic structure and might not include additional costs related to installation, site preparation, or permits.

In recent years, the construction industry has witnessed a significant transformation with the advent of prefabricated metal buildings. These innovative structures have become increasingly popular due to their versatility, cost-effectiveness, and speed of construction. As society continues to seek solutions that are both sustainable and efficient, prefabricated metal buildings stand out as a compelling option for various applications, from commercial spaces to residential homes.

In recent years, the architectural landscape has witnessed a remarkable resurgence in the popularity of metal buildings, particularly those painted in the nostalgic hue of barn red. This color evokes a sense of warmth and tradition, drawing inspiration from the classic barns that dot the countryside. Barn red metal buildings are not only a striking visual choice but also represent a blend of functionality, durability, and timeless appeal.

The Advantages and Future of Steel Structure Factories

One of the key features of prefabricated buildings is their versatility. They can be customized to meet a variety of needs, from industrial warehouses and manufacturing facilities to retail spaces and residential homes. The flexibility in design makes them an attractive choice for a wide range of applications, allowing contractors to tailor the buildings to specific requirements.

In recent years, as the agricultural industry continues to evolve, the demand for more efficient, cost-effective, and sustainable solutions has never been greater. One of the most promising innovations in this sector is the use of prefab (prefabricated) farm buildings. These structures, manufactured off-site and assembled on location, offer numerous advantages that cater to the needs of modern farmers.

The design of narrow metal sheds can also be customized to suit various aesthetic preferences. While many people may think of traditional, drab metal structures, modern manufacturers offer a range of colors and finishes that can complement any home or garden. Whether you prefer a classic look or something more contemporary, there’s likely a narrow metal shed that fits your style. Additionally, many designs incorporate ventilation systems, windows, and even skylights, allowing natural light to filter in and creating a pleasant workspace or storage area.

narrow metal shed

Environmentally Friendly Choice

1. Material Quality

Conclusion

The Advantages of All Metal Sheds A Comprehensive Overview

Understanding the Cost of Building a Metal Garage

The Importance of Metal Warehouse Kits for Efficient Storage Solutions

Additionally, the speed of construction reduces the time before the hanger can be used, providing a quicker return on investment. For airlines and aircraft operators, this means less downtime and more efficient use of resources. The modular nature of prefabricated hangers also allows for future expansion or modification, providing flexibility and scalability as operational needs change.

Versatility and Customization

One of the primary benefits of a metal shed is its durability. Made from high-quality galvanized steel or aluminum, these sheds are resistant to warping, cracking, and rotting—common issues faced by wooden sheds. Additionally, metal sheds can withstand extreme weather conditions, ensuring that your stored items remain safe and sound throughout the seasons. Unlike wooden structures that may require regular upkeep and maintenance, a 12x10 metal shed can serve you well for years with minimal care.

Conclusion

Space Efficiency

Understanding the pricing landscape of steel office buildings is essential for stakeholders in the construction industry, from architects to developers and investors. With prices influenced by global supply and demand, raw material costs, technological advancements, and regional factors, it is crucial for professionals to stay informed and proactive in their strategies. As the industry continues to evolve, embracing steel as a primary material will likely remain a viable choice, balancing cost, sustainability, and modern architectural designs. As businesses seek to optimize their investments while navigating an ever-changing market, the adaptability and resilience of steel office buildings will endure as a cornerstone of contemporary construction.

The need for skilled labor is also on the rise, creating job opportunities in fabrication, assembly, and engineering. As steel buildings become more commonplace, training programs for workers specializing in steel construction are becoming increasingly vital.

Cost-Effectiveness

A Smart Investment

Modular construction also guarantees a higher level of quality and precision. Steel frames are manufactured in factories with stringent quality control processes, ensuring that each component meets specific standards. This precision reduces the likelihood of errors during assembly and enhances the overall structural integrity of the building. Additionally, the uniformity in steel components leads to fewer on-site adjustments, resulting in a more streamlined construction process.

The right choice in high R-value insulation is yet another way to limit overhead spending. Not only will it keep your warehouse at a cozy 70 degrees, but it can also limit indoor humidity that can warp products like furniture and books.

One of the most appealing aspects of metal office warehouse buildings is their design flexibility

. These structures can be tailored to meet specific business needs, whether it’s creating spacious warehouse areas, creating office sections, or adding features like loading docks and mezzanine floors. The open floor plans common in metal buildings lend themselves well to customization, allowing businesses to adapt the space as they grow or change their operational needs.