The electrical control box, on the other hand, is what?

Users can operate and monitor a piece of equipment using a Control Box, a physical interface. A container housing the mechanism or device that regulates and controls anything (mainly electrical or radio waves) within a system.

An electrical control box is analogous to a human body: Our bodies have essential organs that regulate and monitor our environment. Control panels for mechanical processes are similar in that they contain crucial electrical equipment for controlling and electronically monitoring the operation. Industrial equipment and machinery require well-defined functions and systematic control to meet diverse process objectives. In manufacturing equipment, control boxes provide these roles.

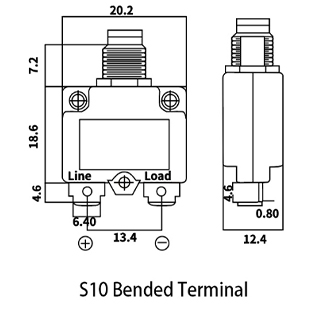

STRUCTURE OF CONTROL PANELS

The construction of a control panel consists of an enclosure and numerous distinct types of electrical components. These components define and arrange the various functions carried out by the control panel. These components include:

When comparing prices for floor marking tape, it is important to consider the durability and longevity of the product. Cheaper tapes may be more cost-effective in the short term, but they may wear down quickly and need to be replaced more often. On the other hand, higher-priced tapes are often made with stronger materials that can withstand heavy foot traffic and machinery.

Black PVC electrical tape is a type of adhesive tape made from polyvinyl chloride (PVC), a synthetic plastic polymer. It is designed specifically for electrical insulation and protection. The tape is coated with a pressure-sensitive adhesive that ensures strong bonding with various surfaces, which is critical for creating secure electrical connections.

3. Durability and Flexibility The tape needs to maintain its integrity under mechanical stress. It should be flexible enough to wrap around busbars securely while also being tough enough to resist wear and tear over time.