fine mesh screen material

Latest articles

fine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read More

fine mesh screen materialBlade thorn rope because the volume is relatively large so thorn rope factory is used to packaging treatment.

...

fine mesh screen material 【fine mesh screen material】

Read Morefine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read Morefine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read More

fine mesh screen material

Post time: 15-06-22...

fine mesh screen material 【fine mesh screen material】

Read MoreIn this temperature range, the zinc solution is severely corroded to the workpiece and the zinc pot, and the iron is lost at 560 degrees Celsius to add obviously, and the zinc will be the iron substrate above 660 degrees Celsius, zinc slag will be added quickly, plating cannot be used. Therefore, electroplating is carried out in the range of 430~450 degrees Celsius.

fine mesh screen material...

fine mesh screen material 【fine mesh screen material】

Read Morefine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read More

fine mesh screen materialLarge coil galvanized wire is made of high quality low carbon steel wire rod processing, is made of high quality low carbon steel, after drawing molding, pickling rust removal, high temperature annealing, hot dip galvanized. Cooling process and other processing. Galvanized wire is divided into hot galvanized wire and cold galvanized wire. Galvanized wire in the process of smelting there are a lot of need to pay more attention to the place, galvanized wire products in the manufacturing process will experience a lot of process, of which the following galvanized wire annealing is a very important step, this step to the nature of galvanized wire has brought a lot of help.

...

fine mesh screen material 【fine mesh screen material】

Read Morefine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read Morefine mesh screen material

...

fine mesh screen material 【fine mesh screen material】

Read More

Popular articles

- Compared with the traditional braided barbed rope, the blade barbed rope has a relatively complex technology and a relatively high cost of raw materials.

Blade thorn rope because the volume is relatively large, so the thorn rope factory is used to packaging.

Now it is more used in the binding of the construction industry. Compared with ordinary iron wire, it is softer and has better luster. Use in daily life does not need to carry out maintenance and maintenance, save a lot of time, but also save the cost of maintenance and maintenance. Annealed wire has good stability, good corrosion resistance, greatly prolonging the service life. More kinds, can be selected according to different uses, making annealing wire device is simple, improve the utilization rate of the device. The material properties of annealed wire can meet different processing requirements.

And high quality data and production cost and production conditions are bound, so some welding screen manufacturers did not meet the requirements of this aspect, natural in this case there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

Latest articles

-

Alias: gabion mesh, heavy hexagonal mesh, ecological mesh, wire mesh, etc.

-

3. The structure of the dog cage should be reasonable

-

Pet cage has many types, and selective is bigger, pet cages are generally made of wire, with better coarse, then at the bottom with a wheel base, such a simple pet basket was made, in the wheel at the bottom of the mount is for the convenience of the mobile, a pet cages should also adapt to the location of the production in addition to a door, It is convenient for feeding pets.

-

-

Pure zinc is more stable in dry air. In moist air or water containing carbon dioxide and oxygen, the surface will generate a layer of basic zinc carbonate based thin film layer, which can delay the corrosion rate of zinc layer. Comparison of corrosion resistance of zinc coating in aqueous solution of acid, alkali and sodium chloride; It is also resistant to corrosion in atmospheres containing carbon dioxide and hydrogen sulfide and in oceanic atmospheres; In high temperature and high humidity air and contain organic acid atmosphere is small, galvanized layer is also easy to be corroded.

-

The anticorrosion of these raw materials are very different, the use of life is not the same. Cattle fence cold galvanized, also known as electroplating, galvanized little, rust in rain, but the price is cheap, the use of life in 5-6 years. Hot dip galvanizing (low zinc and high zinc) zinc content in 60 grams to 400 grams, the use of life is about 20-60 years, corrosion resistance is general.

Links

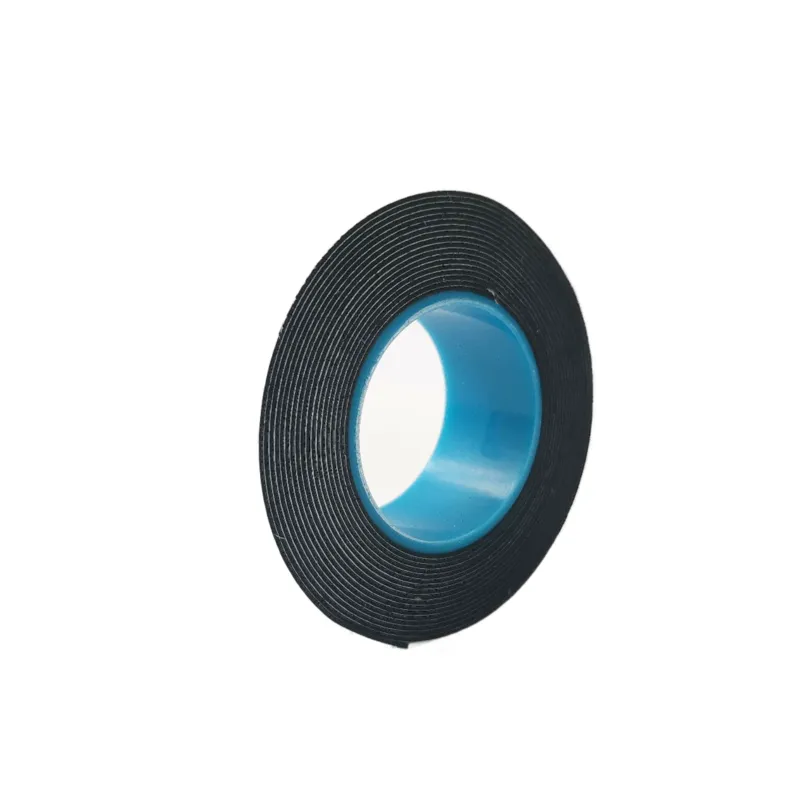

Splicing tape is an essential tool in the world of film production and editing. It is used to connect different pieces of film together seamlessly, allowing for smooth transitions between scenes and shots. Splicing tape comes in various types, each serving a specific purpose in the editing process.

Tape

- Versatility and Ease of Use

- In conclusion, the humble 25mm insulation tape is more than just a strip of sticky material; it's a vital component in electrical safety and maintenance. Its versatility, durability, and the role it plays in preventing electrical mishaps make it an indispensable tool in our daily lives. As technology continues to evolve, so does the importance of understanding and utilizing tools like the 25mm insulation tape effectively.

- Chemical Resistance – Polyester offers good resistance to many chemicals, solvents, and oils. It can withstand exposure to a wide range of chemicals without significant degradation, making it suitable for applications in harsh chemical environments.

It’s important to consider the specific requirements of the application, including temperature range, mechanical stress, chemical exposure, electrical properties, and budget when selecting the most suitable carrier material for adhesive tapes. Each material has its advantages and is chosen based on the specific demands of the application.

The Importance of Choosing the Right Butyl Rubber Tape Supplier

Get more information on product selection, applications and training in our Electrical Resource Center.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.Solvent rubber

Furthermore, temporary floor marking tape is not limited to industrial or commercial applications. It can be used in schools, hospitals, and even at home. In educational settings, teachers can use the tape to create engaging learning environments, designating areas for group activities or marking spots for social distancing. Meanwhile, homeowners can utilize the tape for DIY projects or to organize storage areas, making it a versatile tool for various applications.

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes.

warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes. Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.

electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.The use of control boxes goes beyond typical day-to-day use and this is a testament to their tremendous rewards. Utilizing one of these boxes is likely to benefit you in the following ways;

- Renewable Energy In solar and wind power systems, the insulation of busbars is crucial for protecting the components from harsh environmental conditions, ensuring efficiency and reliability.

The Importance of Fireproof Gasket Tape in Safety and Efficiency

We all know that electrical tape is an important part of any electrical job. But what many people don’t know is what temperature does electrical tape melt?

The key to selecting the right electrical tape for your application.

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work cloth insulation tape. Even in the arts and crafts world, its adhesive strength and colorful options make it a popular choice.

cloth insulation tape. Even in the arts and crafts world, its adhesive strength and colorful options make it a popular choice.Self-fusing silicone electrical tape finds applications across various industries. In electrical installations, it is commonly used for insulating splices, protecting wiring, and securing cables in both residential and commercial projects. Its resistance to heat makes it an ideal choice for high-performance applications, such as in automotive and aerospace sectors.