replacing fly screen mesh

Latest articles

Of course, the quality of any kind of product is also affected by the implementation of the specification of the manufacturer, if it is the welding screen manufacturers in the production of their own is not very high implementation of the specification, or in the production line of the procedure specification has declined, or there is no higher requirements on the production link.

replacing fly screen mesh...

replacing fly screen mesh 【replacing fly screen mesh】

Read More

replacing fly screen meshA. When the thickness of the plating is 3-4 mm, the zinc adhesion should be less than 460g/m, that is, the average thickness of the zinc layer is not less than 65 microns.

...

replacing fly screen mesh 【replacing fly screen mesh】

Read More

replacing fly screen mesh

Post time: 24-08-22...

replacing fly screen mesh 【replacing fly screen mesh】

Read Morereplacing fly screen mesh

...

replacing fly screen mesh 【replacing fly screen mesh】

Read MoreAttention should be paid to line collection and operation. Others shall not get on the train without the monitor’s consent. The wire reel should be put lightly, stacked firmly and neatly, not more than 5 discs. It is forbidden to contact human skin directly with acid and base. When the acid fog exceeds the specified target of the state, timely measures should be taken to control it; otherwise, production is not allowed.

replacing fly screen mesh...

replacing fly screen mesh 【replacing fly screen mesh】

Read MoreFor example, the following circumstances may lead to rust of 304 stainless steel pet cage:

replacing fly screen mesh...

replacing fly screen mesh 【replacing fly screen mesh】

Read More

replacing fly screen mesh

Post time: 06-06-22...

replacing fly screen mesh 【replacing fly screen mesh】

Read Morereplacing fly screen mesh

...

replacing fly screen mesh 【replacing fly screen mesh】

Read More

replacing fly screen meshUsing activated carbon mat to remove surface active substances, or through filtration to make the foam is not too stable, this is an effective measure; Other measures should also be taken to reduce the amount of surfactant introduced to Z.

...

replacing fly screen mesh 【replacing fly screen mesh】

Read MoreMaterial: low carbon steel wire (iron wire, stainless steel, aluminum). Features: net average, bright appearance, textile, concise, crocheting, beautiful not stingy. Mesh screen image quality and width, thickness, erosion, long life, applicability. Hook fence nets are tied as consistently as tennis chain fences because they are easily installed. Hook mesh is also called diamond mesh, hook mesh, galvanized hook mesh, plastic wrapped hook mesh, hook mesh is made of hook mesh machine for all kinds of materials of wire hook knitted, can be divided into folding shrink, screw lock two kinds. Material: PVC wire, stainless steel wire, low carbon steel wire, galvanized wire, iron wire, etc.

replacing fly screen mesh...

replacing fly screen mesh 【replacing fly screen mesh】

Read More

Popular articles

Black iron wire application in the process, the main is through the hot metal billet rolling into six point five mm wire rod, and then put it in the drawing into a line of different diameter, the plant and then gradually narrow drawing plate aperture, cooling and annealing, plating process, such as making a variety of different specifications of the wire, the wire compared with ordinary black iron wire, will be more softer, Softness is also very uniform, color is also consistent, widely used in the construction industry, mining, chemical industry, welding mesh, welding coat hanger, reprocessing industry and so on.

If not packaged, then a car of blade thorn rope can not be loaded with many pieces, but also relatively occupied places and easy to be lost in the process of transportation. Each bundle of blade barbed rope is 50 bundles. After hydraulic compression, the volume is reduced and it is more convenient to load and unload. Forklift trucks can load and unload easily. In general, when exporting, the blade thorn rope will be packaged for sale, so that the volume occupied in the container is relatively small, which can be very easy to size and place will not take up much place.

Post time: 18-05-22

Latest articles

-

-

-

-

-

Aquaculture galvanized electric welding net this mesh structure is convenient for construction, to ensure quality. Compared with the traditional manual binding, it can ensure the quality of the project, shorten the construction of drug control and shorten the construction period. So now such grids are also being used in new rural construction to enhance wall tension and to prevent earthquakes.

-

Links

- Door & Window Hardware The Heart of Architectural Functionality

5. Check Alignment After making your adjustments, check if the door is level. Use a level if necessary. If the door leans to one side, you may need to adjust one roller more than the other to achieve a balance.

- Cast iron wood burning stoves have been a popular choice for heating homes for centuries. These stoves provide a cozy and efficient way to heat a living space while also adding a touch of rustic charm to any room. In this article, we will discuss the benefits of cast iron wood burning stoves and why they are a great option for anyone looking to invest in a reliable heating source.

Thus, you can use it in any environment and still attain desirable results.

Thickness - Overall, gate lock boxes made from weldable steel are a reliable and effective solution for securing gates and protecting properties. Their durability, weather resistance, and tamper-proof features make them an ideal choice for both residential and commercial applications. With easy installation and long-lasting performance, weldable steel lock boxes provide a strong and secure barrier against unauthorized access.

Note: When choosing the right ball post cap size for your building needs, the hole size refers to the outside size of your material. For example, if you are using 2” square material for your project, you would choose the 2” hole size, so it will slip over top.

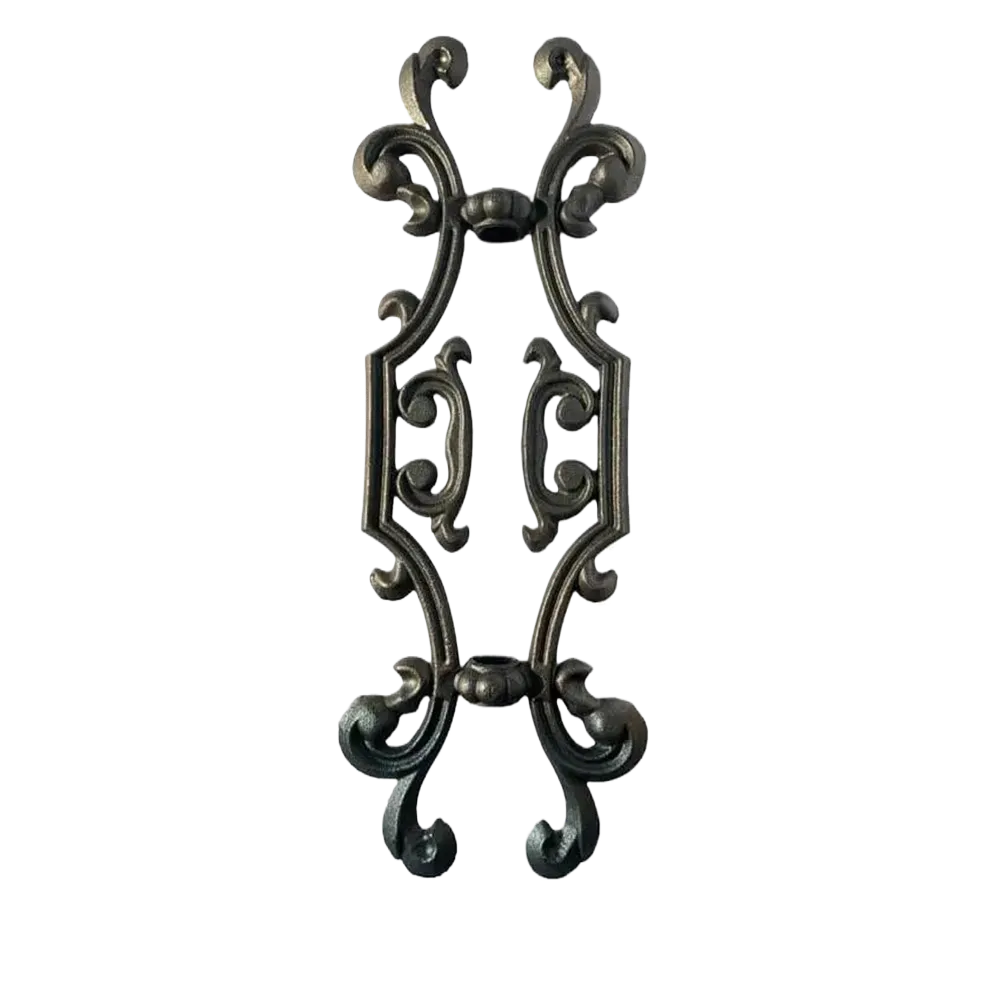

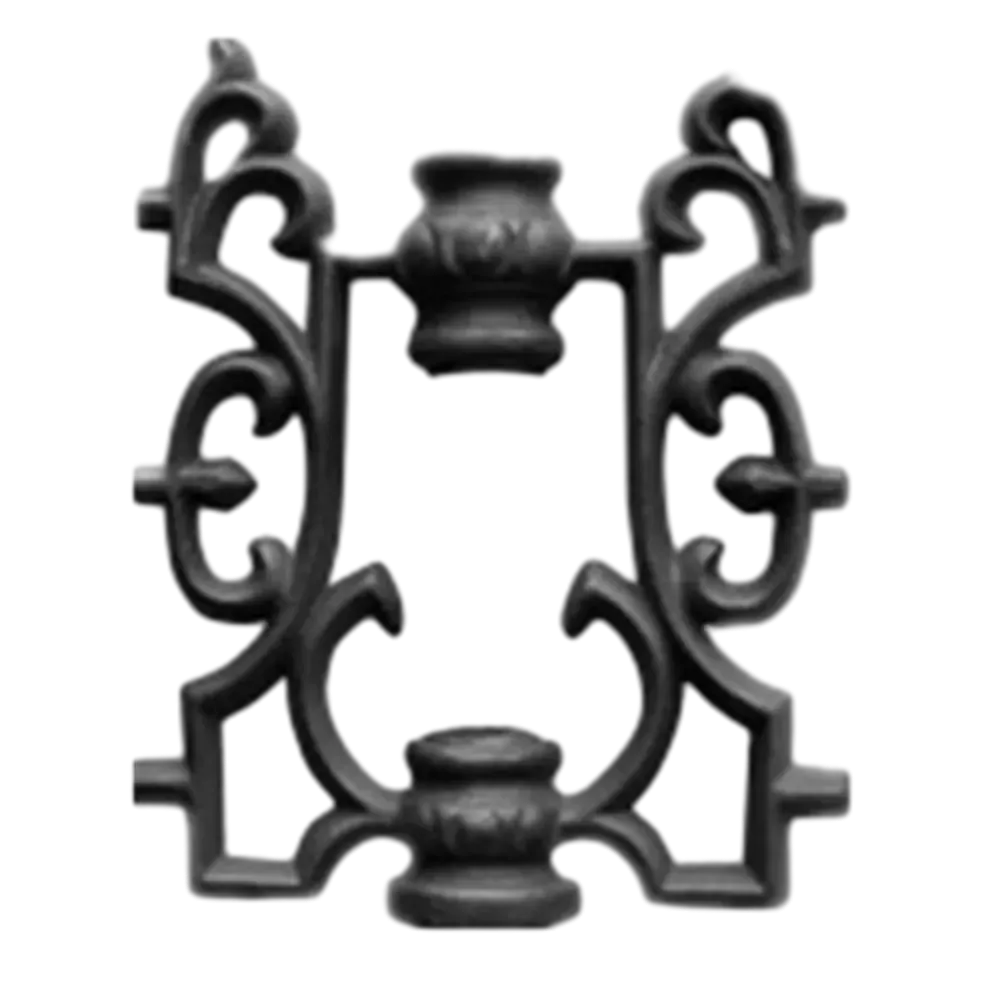

decorative cast iron or iron elements are ideal for ending or completing the railing or fences. .

steel lock box double. Despite its sturdy construction, it is designed to fit neatly in small spaces, making it ideal for home, office, or travel use. Its compact design also makes it easy to transport, allowing you to take your valuables with you wherever you go.

steel lock box double. Despite its sturdy construction, it is designed to fit neatly in small spaces, making it ideal for home, office, or travel use. Its compact design also makes it easy to transport, allowing you to take your valuables with you wherever you go. stainless steel barn door handles. Most handles come with all the necessary hardware and instructions, making it a simple process to attach them to your door. With just a few basic tools and some patience, you can have your new handles installed and functioning in no time.

stainless steel barn door handles. Most handles come with all the necessary hardware and instructions, making it a simple process to attach them to your door. With just a few basic tools and some patience, you can have your new handles installed and functioning in no time.

aluminium sliding wheel. The clean lines and smooth finish of aluminium create a contemporary look that complements a wide range of architectural styles. Whether you are installing sliding doors in a modern home or updating a traditional space, aluminium sliding wheels can add a touch of sophistication to any design.

aluminium sliding wheel. The clean lines and smooth finish of aluminium create a contemporary look that complements a wide range of architectural styles. Whether you are installing sliding doors in a modern home or updating a traditional space, aluminium sliding wheels can add a touch of sophistication to any design.Recycling wrought iron helps conserve natural resources and reduces the environmental impact associated with mining and processing new materials. By choosing to recycle, you contribute to environmental sustainability and help reduce landfill waste.

6. Coatings and Finishes

Moreover, wrought iron railing panels offer a high level of customization. Clients can work closely with artisans to design panels that complement their specific architectural style or personal preferences. Whether it's a classic, Victorian-inspired pattern or a more contemporary, minimalist design, wrought iron railings can be tailored to fit any aesthetic.

wrought iron railing panels

Begin by closing the door and securely locking it to prevent it from swinging open during adjustment Begin by closing the door and securely locking it to prevent it from swinging open during adjustment

Begin by closing the door and securely locking it to prevent it from swinging open during adjustment Begin by closing the door and securely locking it to prevent it from swinging open during adjustment adjusting screen door rollers. Locate the screws or clips holding the roller in place. For screws, use a screwdriver to loosen them slightly but do not remove them completely. For clips, press down on the tab or lever to release the tension. Once loosened, gently lift or push the roller into the desired position. Ensure that the roller is parallel to the ground and evenly spaced from the door's edge. Re-tighten the screws or re-engage the clips, ensuring they are snug but be careful not to over-tighten, which can cause damage to the door or frame.

adjusting screen door rollers. Locate the screws or clips holding the roller in place. For screws, use a screwdriver to loosen them slightly but do not remove them completely. For clips, press down on the tab or lever to release the tension. Once loosened, gently lift or push the roller into the desired position. Ensure that the roller is parallel to the ground and evenly spaced from the door's edge. Re-tighten the screws or re-engage the clips, ensuring they are snug but be careful not to over-tighten, which can cause damage to the door or frame.

Preservation and Restoration

There is no absolute cost for aluminum profiles for windows and doors. Notably, several factors influence the specific amount you pay to obtain these components, such as follows;

As the technical content and the degree of mechanization of doors and windows are not high, most of them rely mostly on the manual operation of the installation workers, which requires the operators to have a good sense of product quality. It is important to strengthen the proficiency of the operators and their product awareness during the production process. High-quality aluminium windows should acquire the following qualities: fine processing, consistent angle (the main frame is usually 45 or 90 degrees), no obvious gaps during the splicing process, good sealing performance and smooth operation.

Adjusting Rollers on Sliding Doors A Comprehensive Guide

They can be painted in a variety of colors to match the surrounding landscape or left to weather naturally, developing a patina that adds a rustic charm They can be painted in a variety of colors to match the surrounding landscape or left to weather naturally, developing a patina that adds a rustic charm

They can be painted in a variety of colors to match the surrounding landscape or left to weather naturally, developing a patina that adds a rustic charm They can be painted in a variety of colors to match the surrounding landscape or left to weather naturally, developing a patina that adds a rustic charm wrought iron fence spear points.

wrought iron fence spear points.Aluminum profiles are cost-effective in the long run due to their durability and low maintenance, but intial costs may vary. It is vital that people balance quality and budget constraints before choosing their ideal aluminum profile.

One of the key benefits of using aluminium for window frames is its strength-to-weight ratio. Aluminium is significantly lighter than traditional materials like steel, yet it maintains exceptional strength, allowing for larger glazing areas. This characteristic enables architects and builders to design windows that maximize natural light while providing a contemporary look. Additionally, aluminium profiles can be produced in a variety of shapes, sizes, and finishes, giving homeowners and builders ample options to fit different architectural styles.

Both cast iron and wrought iron are susceptible to corrosion over time when their bare surfaces are exposed to the elements. That’s why both materials will require finishing and regular maintenance. However, cast iron generally rusts more slowly than wrought iron and thus can go longer intervals between upkeep.