14 gauge mesh wire

Latest articles

Third, after the production process of cold galvanized wire treatment. Galvanized cold galvanized wire needs to go through a series of post-treatment processes to ensure its quality and performance.

14 gauge mesh wire...

14 gauge mesh wire 【14 gauge mesh wire】

Read More14 gauge mesh wire

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More14 gauge mesh wire

...

14 gauge mesh wire 【14 gauge mesh wire】

Read MoreAttention should be paid to line collection and operation. Others shall not get on the train without the monitor’s consent. The wire reel should be put lightly, stacked firmly and neatly, not more than 5 discs. It is forbidden to contact human skin directly with acid and base. When the acid fog exceeds the specified target of the state, timely measures should be taken to control it; otherwise, production is not allowed.

14 gauge mesh wire...

14 gauge mesh wire 【14 gauge mesh wire】

Read More14 gauge mesh wire

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More

14 gauge mesh wireIn the calculation process of 12*14 specifications of barbed rope, it can not be calculated according to the above calculation formula, because first of all, two specifications of raw materials are used, the thinner the wire diameter, the higher the processing cost. Generally speaking, a kilogram of 12*14 barbed rope can reach about 7.5 meters, and the ratio of warp wire to barbed rope cannot be calculated according to the traditional ratio of 7 to 3. The specific use of how much wire and silk need to go through a series of professional measurement but also increase the loss of raw materials and other factors to calculate. Thorn rope factory will also according to customer needs to calculate the reasonable amount of customer use.

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More2. Quantity and packing

14 gauge mesh wire...

14 gauge mesh wire 【14 gauge mesh wire】

Read More14 gauge mesh wire

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More14 gauge mesh wire

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More

14 gauge mesh wireIn order to pack and bundle galvanized wire on the surface of the deposit layer to remove the surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless. Small homogeneous particles of large denier present in the tank can stabilize the foam layer. To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the intake of surfactant. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

...

14 gauge mesh wire 【14 gauge mesh wire】

Read More

Popular articles

3. Acid activation acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts, without excessive corrosion on the matrix.

- The application range of small hexagonal net is also relatively wide, can be used for building wall fixed insulation layer, pipeline, boiler fixed insulation, decoration and other fields.

- Generally speaking steel does not rust easily with chromium content of 10.5%. The higher the content of chromium and nickel, the better the corrosion resistance, such as 304 material nickel content in 8-10%, chromium content of 18-20%, such stainless steel in general is not rust.

Paint on the galvanized layer, the binding force between each other and the baking temperature of the paint has a great relationship, after galvanized coating alkyd paint, adhesion is no problem. Galvanized amino paint, paint adhesion is not good. Do two bottom two surface, adhesion is ok, if the two bottom two surface to two bottom three surface, that is, more paint, more baking once, again test adhesion is very poor, poor to the paint from the galvanized layer of pieces torn off.

- 3. Scope of application. Electrogalvanizing involves more and more extensive fields, fastener products have been widely used in machinery manufacturing, electronics, precision instruments, chemical industry, transportation, aerospace and so on in the national economy is of great significance.

Latest articles

-

-

-

-

After the corrosion of impregnated hexagonal wire mesh, the original characteristics will be lost, and the shape, color and mechanical properties will be changed, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually, there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment is easier to rust than dry environment, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated six-sided wire mesh, prolong the service life of the product.

-

-

The development of iron wire industry in our country is still very good, among which there is a kind of iron wire called large roll galvanized wire, which is also widely used with its own good performance. In fact, the zinc layer plays a protective effect on the iron wire inside, which can ensure that the iron wire is not oxidized, and it is convenient and beautiful to use. Galvanized iron wire is formed by pickling, high temperature, hot dip galvanizing and other steps. It has good toughness and elasticity and can be applied to many civil fields.

It's also worth considering the weight and ergonomics of the tool. A comfortable grip can significantly enhance the sewing experience, especially during prolonged use. Finally, evaluating the availability of replacement parts and accessories can ensure that the tool remains functional for years to come.

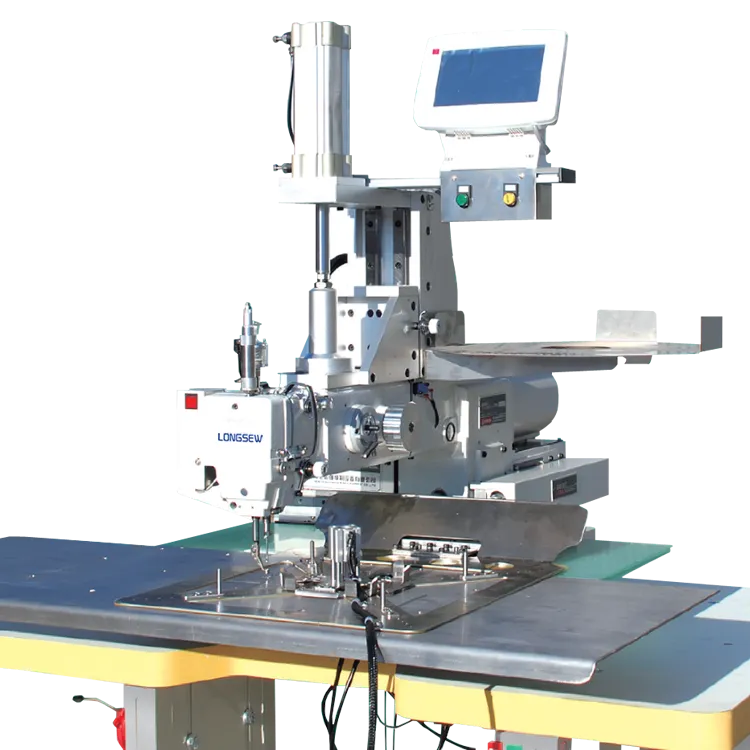

The Importance of Industrial Bag Closing Machine Heads in Modern Manufacturing

- Select the Right Stitch Settings Before you start, adjust your sewing machine’s settings to match the fabric type and intended use of the stitching. Experiment with different widths and lengths to achieve the desired effect.

On the business side, leather sewing machine companies often provide resources and support for their users beyond just the sale of machinery. Many companies offer workshops, tutorials, and online communities where crafters can share techniques, troubleshoot issues, and inspire one another. This sense of community fosters a collaborative spirit, allowing artisans to learn from one another while improving their skills and producing outstanding products.

Using a sailmaker sewing machine not only enhances the quality of the finished product but also significantly reduces the time and effort required to fabricate sails. In a world where efficiency is paramount, having the right tools can mean the difference between meeting deadlines and falling behind. Additionally, the precision that these machines offer ensures that sails are not just aesthetically pleasing but also functionally effective, providing the necessary aerodynamic properties needed for efficient sailing.

The versatility of the walking foot machine extends to a wide range of applications. For quilters, it allows for precise stitching across multiple layers, offering cleaner lines and better quilt integrity. Upholsterers benefit from the machine's ability to handle thick fabrics with ease, while tailors appreciate the control it provides when sewing difficult seams.

1. Motor Power Heavy-duty machines typically have a more powerful motor compared to standard models. Look for machines with a motor rated at least 1.0 amp or higher. A robust motor ensures that your machine can handle thick materials without stalling.

Understanding the Double Needle Walking Foot Industrial Sewing Machine

Heavy-duty leather sewing machines are designed to handle tough materials normally used in leather crafting. These machines have robust construction and powerful motors that can easily sew through multiple layers of leather, thick fabrics, and other heavy materials. Unlike standard sewing machines, heavy-duty models come equipped with more powerful needles and feed systems that allow them to manage challenging materials smoothly.

Another pivotal advantage of modern walking foot machines is their ergonomic design. Many industrial models come equipped with user-friendly features such as adjustable heights, knee lifts, and variable speed controls. These enhancements contribute to a more comfortable working environment and reduce fatigue among operators, which is crucial in high-demand production settings where workers may spend long hours at their stations.

In the world of upholstery, precision and quality are paramount. Whether working on furniture, automotive interiors, or other textile applications, having the right tools is essential. Among these tools, commercial upholstery sewing machines stand out as indispensable equipment for professionals in the industry. This article will explore the significance of these machines, their features, and tips for choosing the right one for your needs.

The price of a cylinder bed sewing machine can vary significantly based on several elements, including brand, features, functionality, and the machine's specific purpose. On average, a standard cylinder bed sewing machine can cost anywhere from $1,000 to $5,000. High-end models with advanced features or greater functionality might exceed this range, potentially reaching prices above $10,000.

What Makes a Heavy Duty Machine Different?

When selecting a sewing machine quilt pattern, consider factors such as your skill level, the type of fabric you want to use, and the overall look you hope to achieve. For beginners, simple block patterns or straight-line designs can be an excellent starting point. More advanced quilters may want to explore intricate patterns such as applique, paper piecing, or curves.

The Brother ST371HD is another highly rated option that shines in durability and ease of use. This machine is specifically designed for heavier fabrics and comes with 37 built-in stitches, including 1-step auto-size buttonholes. It features a metal needle plate, which is essential for sewing thicker materials, and an adjustable presser foot pressure that allows you to tackle different fabric thicknesses effortlessly. Users love its lightweight design, making it easy to transport to sewing classes or workshops.

In the dynamic world of textile manufacturing, precision and efficiency are paramount. One of the machines that play a critical role in achieving these qualities is the single needle edge cutter machine. This specialized equipment is designed to deliver clean and precise cuts on fabric edges, ensuring a high-quality finish for garments and textile products. In this article, we will delve into the features, benefits, and applications of the single needle edge cutter machine, highlighting its importance in the industry.

Industrial Sewing Machines: Given their continuous operation, these machines demand regular and thorough maintenance. However, due to their robust build, they might require less frequent repairs if appropriately maintained.

Heavy-duty and industrial sewing machines serve distinct needs, with the former bridging the gap between household and professional machines. While industrial units excel in continuous, specialized tasks, heavy-duty machines can effectively sew light fabrics when tailored with appropriate settings, such as stitch length, tension control, and needle choices. However, challenges like machine speed, feed dogs, and thread choice need careful management. Regular maintenance and choosing versatile machines, backed by expert advice and reviews, can ensure optimum results across various fabrics, from robust denim to delicate silks.

Additionally, automatic bag closer machines can contribute to a company’s sustainability efforts. By improving efficiency and reducing waste, these machines align with environmentally friendly practices, making it easier for companies to meet their sustainability goals.

In conclusion, when considering the purchase of a portable bag closer machine, it's essential to evaluate your specific needs and the nature of your operations. While price is a significant factor, it should also be weighed against quality, durability, available features, and potential long-term savings. Investing in a reliable portable bag closer machine can enhance operational efficiency and ultimately lead to greater profitability in your business endeavors. Whether you are a small business or a large-scale manufacturer, careful consideration of these factors can lead to a well-informed purchase decision.

Do you have limited space for a sewing setup, or do you have a dedicated sewing room with ample workspace?

One of the primary functions of an overlocker is to sew and trim fabric edges simultaneously. This capability allows for quick and efficient sewing, significantly reducing the time it takes to finish a garment. When working with woven fabrics, the overlocker can quickly create clean and professional seams that do not fray, ensuring the longevity of clothing items. Additionally, the overlocking process often features a rolled hem function, which is particularly useful for lightweight and delicate materials like chiffon or organza, providing a neat finish without the bulk of a traditional hem.

what is an overlocker in sewing

The benefits of these machines extend beyond simply threading the needle. They encourage creativity by making sewing more accessible. Many individuals who may have been intimidated by previous challenges are now able to dive into their craft with enthusiasm. This surge in confidence can lead to the production of diverse projects, from simple altercations to intricate quilts.

double needle stitch. It can also be used with different types of threads, allowing for endless creative possibilities. Double needle stitching can be done with both regular sewing machines and industrial sewing machines, making it accessible to sewists of all skill levels.

6. Enhancing Decorative Elements