hexagonal netting

Latest articles

hexagonal netting

...

hexagonal netting 【hexagonal netting】

Read More4, after brushing, rinse with water. It should be noted that dogs like to lick everywhere. The disinfectant left on the fence is easy to be eaten by dogs, so be sure to flush several times. Finally, take the dog cage to the sun for 1 hour, ultraviolet radiation will make the sterilization effect double!

hexagonal netting...

hexagonal netting 【hexagonal netting】

Read More5. Maintenance and cleaning in the future

hexagonal netting...

hexagonal netting 【hexagonal netting】

Read Morehexagonal netting

...

hexagonal netting 【hexagonal netting】

Read Morehexagonal netting

...

hexagonal netting 【hexagonal netting】

Read Morehexagonal netting

...

hexagonal netting 【hexagonal netting】

Read More

hexagonal nettingAccording to the galvanized iron wire manufacturer, galvanized iron wire is the selection of excellent low carbon steel, through drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. The following points should be paid attention to in the use of galvanized iron wire:

...

hexagonal netting 【hexagonal netting】

Read More

hexagonal netting

Post time: 23-09-22...

hexagonal netting 【hexagonal netting】

Read More

hexagonal netting

Post time: 22-02-23...

hexagonal netting 【hexagonal netting】

Read Morehexagonal netting

...

hexagonal netting 【hexagonal netting】

Read More

Popular articles

After the optimization of the process, mass production of 0.80mm electro galvanized steel wire electro galvanized zinc layer quality is controlled within 80 ~ 90g/m2, zinc layer quality dispersion is very small; The results show that the average weight of zinc layer is 14.5g/m2, the loss of zinc layer is less than 5%, and the tensile strength of steel wire is 2300 ~ 2500MPa. It not only effectively controls the quality of zinc layer of raw steel wire, but also reduces unnecessary waste and production cost.

Post time: 21-03-23Hot dip galvanized coating is also relatively thick, but there is an uneven situation, for example, the thickness of the thin is only 45 microns, thick can reach 300 microns or even thicker, the color of this product is relatively dark. There is also a lot of zinc consumed in the production process. Zinc will form an infiltration layer with the metal. Its advantage is that it has good corrosion resistance. Electrogalvanizing, it is through the plating tank in the zinc one-way plating on the outside of the metal products, this way of making products is relatively slow, but its thickness is more uniform.

Latest articles

-

-

-

A variety of arc, undivided Angle and undivided elevation ladder mounts are available to provide the ideal treatment plan. It can be used together with the appearance and the design of the common trackless active shift door, forming a harmonious and intact whole.

-

-

With the improvement of people’s living standards, kittens, dogs and other small pets also need a stable nest, pet cage has become a more important choice for people to raise pets. Suitable cat cage, dog cage is very necessary for kittens and dogs. There are many kinds of pet cage, cat cage, dog cage selectivity is relatively large, pet cage is generally made of thicker wire, and then get a base with wheels at the bottom, such a simple pet cage is made.

-

For instance, in deep mines where the drilling depth is significant, high-strength, fatigue-resistant drill rods are preferred to counteract the increased stress and strain For instance, in deep mines where the drilling depth is significant, high-strength, fatigue-resistant drill rods are preferred to counteract the increased stress and strain

For instance, in deep mines where the drilling depth is significant, high-strength, fatigue-resistant drill rods are preferred to counteract the increased stress and strain For instance, in deep mines where the drilling depth is significant, high-strength, fatigue-resistant drill rods are preferred to counteract the increased stress and strain coal mining drill rod.

coal mining drill rod.Standards and Compliance

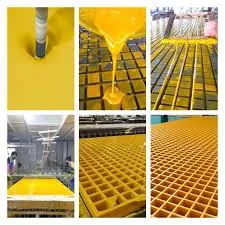

FRP grating can be used in a variety of applications from chemical plants to wastewater treatment facilities to swimming pools and more. It is also a great choice for industrial flooring applications because of its strength and durability as well as its slip-resistant surface texture which helps reduce the risk of slips and falls on wet surfaces. FRP grating is also an excellent choice for industrial staircases since its lightweight properties make installation much easier than other types of staircases while still providing an incredibly strong and slip resistant walking surface that will last for a long time.

In the future, the joint laboratory will also develop a variety of high-performance lightweight composite products and technologies, serving the automotive, aerospace, industrial machinery and other industries.

Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string

Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string drill rod connections.

drill rod connections. With proper training and safety precautions, anyone can learn how to use this powerful machine effectively With proper training and safety precautions, anyone can learn how to use this powerful machine effectively

With proper training and safety precautions, anyone can learn how to use this powerful machine effectively With proper training and safety precautions, anyone can learn how to use this powerful machine effectively power jack hammer. This makes it a popular choice among contractors, builders, and other professionals who work in the construction industry.

power jack hammer. This makes it a popular choice among contractors, builders, and other professionals who work in the construction industry.Another significant benefit of using FRP grating is that it is cost-effective compared to other types of flooring or structural supports. Its minimal maintenance requirements mean that there are fewer costs associated with keeping it in good condition over time. This includes occasional cleaning with soap and water or an approved cleaner if needed. Repairs or replacements are very rarely required. This makes fiberglass grating an attractive option for anyone looking for an affordable yet reliable solution for their project needs.

Hengshui Jrain, completed a lot of FRP fittings for our Australia customer, and they were loaded from workshop today. Hope their travel oversea is joyful.

anchor bit. If a ship loses power or control, the anchor bit is the first line of defense, literally and metaphorically. It initiates the anchoring process, potentially saving the ship from drifting into dangerous waters or colliding with other vessels.

anchor bit. If a ship loses power or control, the anchor bit is the first line of defense, literally and metaphorically. It initiates the anchoring process, potentially saving the ship from drifting into dangerous waters or colliding with other vessels. Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport

Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport fiberglass insulation tank. This is particularly beneficial for applications where space is limited or where weight is a concern.

fiberglass insulation tank. This is particularly beneficial for applications where space is limited or where weight is a concern. jack hammer for sale near me. These establishments pride themselves on offering an array of models, accessories, and parts, ensuring that every customer finds a tool tailored to their specific needs. They are havens for professionals and hobbyists looking to acquire not just a tool, but a piece of craftsmanship that will endure through countless projects.

jack hammer for sale near me. These establishments pride themselves on offering an array of models, accessories, and parts, ensuring that every customer finds a tool tailored to their specific needs. They are havens for professionals and hobbyists looking to acquire not just a tool, but a piece of craftsmanship that will endure through countless projects.