perforated steel angle iron

Latest articles

perforated steel angle ironUnder any application environment, users hope that the welding mesh has better strength, as long as it has improved in strength, it will make better use of the demand, but to make the strength of this product improve, also need to have many conditions, to see what kind of data manufacturers have in production, the strength of the product is the strength of the data, But a manufacturer does not meet the strength requirements in the data, and naturally, it cannot make the strength of the product improve after all, so this is the condition.

...

perforated steel angle iron 【perforated steel angle iron】

Read Moreperforated steel angle iron

...

perforated steel angle iron 【perforated steel angle iron】

Read Moreperforated steel angle iron

...

perforated steel angle iron 【perforated steel angle iron】

Read More2. When there are channels, ponds, lakes and other natural barriers on the side of the road, there is no need to worry about people and animals entering and illegally occupying the road land.

perforated steel angle iron...

perforated steel angle iron 【perforated steel angle iron】

Read More

perforated steel angle iron

Post time: 01-02-23...

perforated steel angle iron 【perforated steel angle iron】

Read Moreperforated steel angle iron

...

perforated steel angle iron 【perforated steel angle iron】

Read More

perforated steel angle iron

Post time: 24-02-23...

perforated steel angle iron 【perforated steel angle iron】

Read Moreperforated steel angle iron

...

perforated steel angle iron 【perforated steel angle iron】

Read More

perforated steel angle iron1. Choose the right cage for your dog according to its size

...

perforated steel angle iron 【perforated steel angle iron】

Read Moreperforated steel angle iron

...

perforated steel angle iron 【perforated steel angle iron】

Read More

Popular articles

- Preparation process: single twist plait, double twist plait.

1. The diameter of the raw material and the thickness of the diameter are directly affected;

The barbed wire factory will store the inventory of the barbed wire blade in the appropriate place because of the understanding of the product characteristics.

3. The structure of the dog cage should be reasonable

Latest articles

-

5. Maintenance and cleaning in the future

-

-

-

-

The drawing process of waste product drawing process has a great influence on product function. Generally, large total surface reduction rate (see area reduction rate) and small pass surface reduction rate (about ≤23%) are selected to ensure the tolerance of products. About high strength spring steel wire, the exit temperature of each pass steel wire should be controlled when drawing below 150℃, to prevent the steel wire from changing cracks due to strain aging, which is the main disadvantage of steel wire obsoletion.

-

Post time: 29-07-22

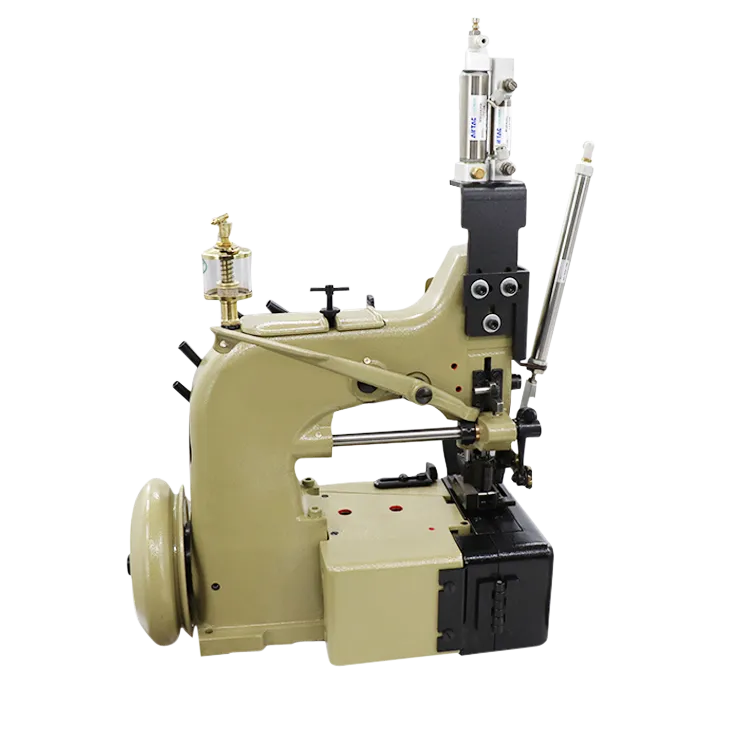

In conclusion, a double needle walking foot sewing machine is a smart investment for anyone serious about sewing. Its ability to handle a variety of fabrics, the precision it offers, and the creativity it encourages through decorative stitching makes it a sought-after tool for both novice and experienced sewists. With careful consideration and research, you can find the perfect double needle walking foot sewing machine for your sewing adventures, setting you on the path to creating beautiful, professional-quality projects. Happy sewing!

2. Needle and Presser Feet Heavy-duty machines often come with specialized needles and presser feet designed specifically for leather. This will prevent skipping stitches and ensure clean, precise lines.

- Upholstery Whether you’re recovering furniture or making cushions, heavy duty needles are ideal for sewing through thick upholstery fabrics and batting.

heavy duty sewing needle

3. Versatility Double needle machines are versatile. They can sew various types of fabrics, including knits, woven fabrics, and materials that require stretch. This capability makes them suitable for various projects beyond garment construction, including home textiles and upholstery work.

However, like any tool, handheld leather sewing machines come with their own set of limitations. They may not match the speed or power of a traditional sewing machine, especially when it comes to larger or thicker materials. Consequently, while they are perfect for small projects and quick repairs, crafters may still need to rely on more robust machines for larger tasks.

Heavy-duty mechanical sewing machines are built with robust materials and components. They often feature a metal frame that provides stability and reduces vibrations during operation, ensuring precise stitches. The heavy-duty presser foot is another key element; it exerts more pressure on the fabric, allowing for smooth feeding of multiple layers and thicker materials without skipping stitches. These machines typically come with a range of stitch options, including straight stitch, zigzag, and specialized stitches like bar tacks, which are frequently needed in heavy sewing projects.

- Built-in Stitch Options Depending on your projects, you may want a machine that offers different stitch types, including straight, zigzag, and decorative stitches.

double needle saddle stitch. This stitching technique can be used on a wide range of materials, including leather, fabric, and paper. It can also be adapted to create different decorative patterns and designs, making it a popular choice for customizing products and adding a touch of personalization.

Understanding Lockstitch Sewing Machines

One of the key advantages of jumbo bag sewing machinery is its ability to automate the sewing process. Traditional sewing methods can be labor-intensive and time-consuming, often resulting in inconsistencies in quality. However, automated jumbo bag sewing machines utilize advanced technology to streamline operations. These machines can sew multiple bags simultaneously, significantly reducing production time and labor costs. Furthermore, with the integration of computer numerical control (CNC) technology, manufacturers can achieve precise stitching patterns and dimensions, enhancing the quality of the final product.

Understanding the Lockstitch Sewing Machine A Vital Tool in Textile Production

However, despite its advantages, using a zig zag stitch machine does come with its own set of challenges. Proper tension settings, stitch length, and needle choice are all critical factors that can influence the final outcome of a project. Seamstresses should take the time to familiarize themselves with their specific machine and practice different techniques to achieve the best results.

The environmental impact of footwear production is an ongoing concern, with traditional methods often leading to waste and excess material use. Automatic shoe sewing machines contribute to more sustainable practices by optimizing material usage and reducing off-cuts. Advanced software solutions are also being integrated to track material consumption and streamline processes further, allowing manufacturers to adopt more eco-friendly practices.

4. Type of Machine While the focus here is on single needle sewing machines, it’s important to consider that there are specialized models within this category. For instance, heavy-duty machines designed to handle thicker fabrics or those equipped for quilting purposes may come at a premium compared to standard models. Understanding the specific type of sewing you intend to do can guide you toward the right machine.

single needle machine price

industrial overlocker for sale. Look for machines that are user-friendly and come with clear instructions and support materials. Additionally, consider the availability of replacement parts and accessories, as well as the ease of servicing and repairs. A machine that is easy to maintain and keep in good working order will save you time and money in the long run.

industrial overlocker for sale. Look for machines that are user-friendly and come with clear instructions and support materials. Additionally, consider the availability of replacement parts and accessories, as well as the ease of servicing and repairs. A machine that is easy to maintain and keep in good working order will save you time and money in the long run.As technology progresses, compound feed sewing machines are also evolving. Manufacturers are now incorporating advanced features such as digital control systems and automated adjustments, allowing for greater precision and customization. These innovations not only facilitate easier operation but also improve the overall quality of the stitching process.

No matter which sail making sewing machine you choose, be sure to carefully read the product specifications and reviews before making a purchase. Consider your own skill level and the types of projects you will be working on to ensure that you select a machine that meets your needs.

Another application of the two needle stitch is in home décor and upholstery. From curtains to cushions, this technique provides a robust seam that can withstand the rigors of everyday use. The added strength of the parallel stitching ensures that seams remain intact despite the stresses placed upon them. It also allows for creative opportunities, as variations in thread color or patterns can enhance the overall design of home accessories.

two needle stitch

Versatile Features

2. Enhanced Design Options The ability to embroider complex designs with multiple colors simultaneously gives businesses a competitive edge, enabling them to offer customers a wider range of products.

In conclusion, CNC programmable sewing machines are revolutionizing the textile and garment industry by providing unmatched precision, efficiency, and adaptability. As manufacturers continue to seek innovative ways to improve production processes while meeting consumer demands for sustainable and unique products, these advanced machines are likely to play an increasingly pivotal role. The marriage of technology and craftsmanship in sewing not only enhances productivity but also paves the way for a more sustainable and capable future in fashion manufacturing.

Importance of Quality and Safety

climbing rope sewng machine

One of the primary advantages of using a twin needle sewing machine is its ability to produce professional-looking hems, particularly on knit and stretchy fabrics. Traditional single needles can struggle with these materials, often leading to puckering or distortion. However, a twin needle allows for the sewing of two lines of stitches while keeping the fabric securely in place. This results in a flat, well-finished hem, which is essential for garments designed to fit comfortably.

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

The continuous innovation within this segment ensures that these machines not only meet current industry standards but also anticipate future demands. In summation, a bag closing sewing machine is an indispensable tool in modern packaging, combining speed, precision, and adaptability to meet the diverse needs of various industries, thereby playing a critical role in maintaining the quality and safety of packaged goods.

Understanding Auto Sewing Machine Prices Factors and Trends