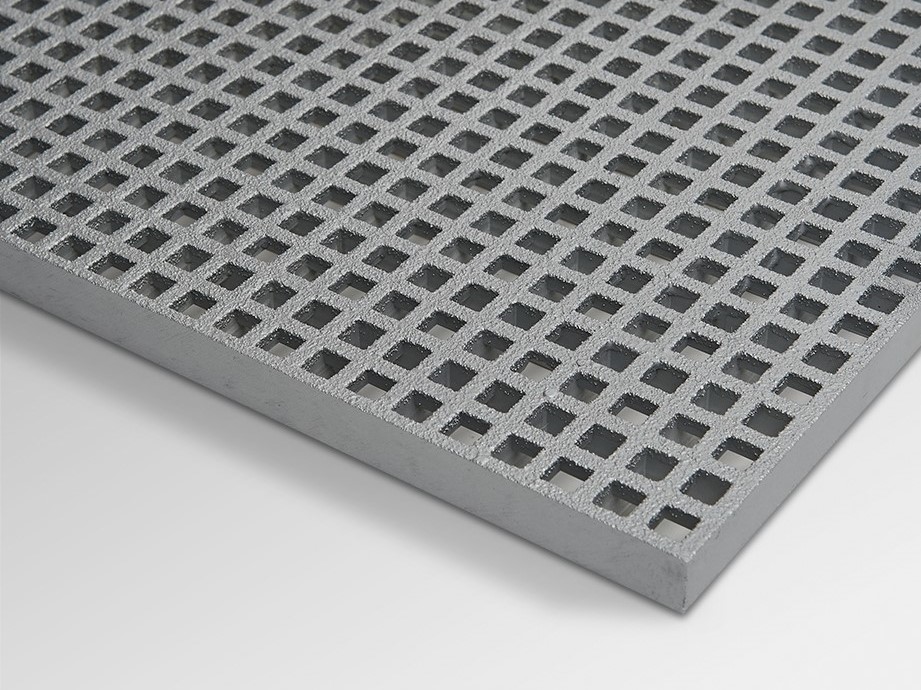

316 stainless steel perforated sheet

Latest articles

316 stainless steel perforated sheetAfter annealing, the wire will become soft, flexibility will increase, iron is a relatively active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron in the dry air is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements, its production cost is lower, use and scale is wider, better protection function, so it is an important material for iron and steel parts in a strict working environment.

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More316 stainless steel perforated sheet

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read MoreWhen pickling, we should pay great attention to the acid has a strong corrosion, so when adding acid, we must pour acid into water, and it is along the wall of the cylinder, not a splash down, so as not to cause splash. Remember the order of pouring acid, acid into water rather than water into acid, water into acid will cause splashing and boiling, when pouring acid must wear protective glasses, must ensure that there are no non-professional onlookers, so as not to cause some risk of splashing acid.

316 stainless steel perforated sheet...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read MoreGalvanized iron wire is divided into hot galvanized wire and cold galvanized wire (electric galvanized wire) is made of low carbon steel, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. Galvanized iron wire has good toughness and elasticity, zinc content can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. The products are widely used in construction, handicrafts, wire mesh, galvanized hook mesh, spackle mesh, highway fence, product packaging and daily civilian and other fields.

316 stainless steel perforated sheet...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More316 stainless steel perforated sheet

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read MoreBarbed wire, on the one hand, is a great protection against livestock theft, because the surface is covered with sharp spikes that make it very difficult to penetrate through the barbed wire. On the other hand, because livestock generally have the habit of bumping, the barbed rope is used to circle, which makes the livestock dare not rush to collide with the barbed rope, so as to save the use cost of users.

316 stainless steel perforated sheet...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More

316 stainless steel perforated sheet

Post time: 06-05-22...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More

316 stainless steel perforated sheetGalvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More316 stainless steel perforated sheet

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More316 stainless steel perforated sheet

...

316 stainless steel perforated sheet 【316 stainless steel perforated sheet】

Read More

Popular articles

- Generally larger birds choose tall but more dense cage, so as not to damage the tail feathers. Although bailing and other small body, but high flying singing habits, with a special high cage.

- Because the barbed rope is a strong use of regeneration value. Generally, the use of discarded guardrail networks for exercise, or steel production of new structural raw materials, do a good job of daily cleaning up and recovery can promote the value of the whole guardrail network faster. Again is to recover the use, the use of it in the appearance of the use of places that are not high, such as as other days purse Seine; Taking apart or discarding the raw materials that do not need to rust can carry out the whole regeneration.

Wire flexibility and elongation is good, can withstand the pressure of mechanical operation, in our country’s industry has played a very important role. There are many kinds of iron wire, the most common is to give black iron wire, galvanized iron wire. The corrosion resistance of the outer coating is effectively improved, but the phenomenon of crevice corrosion will be found after long-term use.

- One end of the wire must be clearly marked and the other end left on the outer layer for easy connection by other wires. Ask the factory to provide the corresponding quality inspection report before packing. Cold drawing is a kind of material often used in our life, especially in the construction of buildings. Cold wire drawing is used more in building materials, cold wire drawing testing standards are also different.

Latest articles

-

-

-

-

In the calculation process of 12*14 specifications of barbed rope, it can not be calculated according to the above calculation formula, because first of all, two specifications of raw materials are used, the thinner the wire diameter, the higher the processing cost. Generally speaking, a kilogram of 12*14 barbed rope can reach about 7.5 meters, and the ratio of warp wire to barbed rope cannot be calculated according to the traditional ratio of 7 to 3. The specific use of how much wire and silk need to go through a series of professional measurement but also increase the loss of raw materials and other factors to calculate. Thorn rope factory will also according to customer needs to calculate the reasonable amount of customer use.

-

In the processing of stainless steel barbed wire after cold galvanized or hot galvanized coating on the surface of the last zinc material, not only beautiful but also plays a good protective role.

-

5, according to the wire diameter thickness to adjust zinc dipping time

In recent decades, carbon aerogels have been widely explored by using graphitic carbons and soft carbons, which show advantages in superelasticity. These elastic aerogels usually have delicate microstructures with good fatigue resistance but ultralow strength. Hard carbons show great advantages in mechanical strength and structural stability due to the sp3 C-induced turbostratic “house-of-cards” structure. However, the stiffness and fragility clearly get in the way of achieving superelasticity with hard carbons. Up to now, it is still a challenge to fabricate superelastic hard carbon-based aerogels.

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces This high level of precision can help prevent errors and ensure that the final product meets the required specifications This high level of precision can help prevent errors and ensure that the final product meets the required specifications

This high level of precision can help prevent errors and ensure that the final product meets the required specifications This high level of precision can help prevent errors and ensure that the final product meets the required specifications The material can be molded into complex shapes, allowing for a streamlined design with fewer joints and seams, thereby minimizing potential weak points The material can be molded into complex shapes, allowing for a streamlined design with fewer joints and seams, thereby minimizing potential weak points

The material can be molded into complex shapes, allowing for a streamlined design with fewer joints and seams, thereby minimizing potential weak points The material can be molded into complex shapes, allowing for a streamlined design with fewer joints and seams, thereby minimizing potential weak points It can handle both potable and wastewater, as well as chemical and industrial fluids, without the risk of contamination It can handle both potable and wastewater, as well as chemical and industrial fluids, without the risk of contamination

It can handle both potable and wastewater, as well as chemical and industrial fluids, without the risk of contamination It can handle both potable and wastewater, as well as chemical and industrial fluids, without the risk of contamination