1 1 2 ring shank coil nails

Latest articles

1 1 2 ring shank coil nails

Post time: 24-02-23...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More6, the use of special formula and special UV absorbent, no fading, no yellowing, no peeling, no cracking, no foaming, no moth, the use cycle can be more than 30 years.

1 1 2 ring shank coil nails...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More1 1 2 ring shank coil nails

...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More1 1 2 ring shank coil nails

...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read MoreThe service condition and service life of electro galvanized iron wire or component are closely related to the thickness of electroplated coating. The more strict the conditions of use and the longer the service life, the thicker the layer of galvanized iron wire required. Different products, according to the specific environment (temperature, humidity, rainfall, atmospheric composition, etc.) to determine the expected service life of the coating thickness, blind thickening will cause all kinds of waste. But if the thickness is insufficient, it will not reach the expected service life requirements. Different manufacturers, according to their own equipment conditions, in the case of determining the plating, the first preparation of a more complete and reasonable process flow, clear plating parameters, control plating solution concentration, standard operation.

1 1 2 ring shank coil nails...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More1 1 2 ring shank coil nails

...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More

1 1 2 ring shank coil nailsImmersed six edge barbed wire corrosion lost the original characteristics, in the shape, color and mechanical properties and other aspects will change, resulting in equipment damage, pipeline leakage, specifically, is prone to fracture, lose the original protection function. Corrosion usually metal corrosion has three types: physical, chemical corrosion and electrochemical corrosion, and corrosion depends on the chemistry of the metal itself and the organizational structure, still have relationship with the surrounding medium, such as wet environment than dry environment is easy to rust, more less than the impurities of impurities is easy corrosion, high temperature conditions than under the condition of low temperature corrosion, etc. After understanding these, we can effectively prevent the corrosion of the six sides of the wire, prolong the service life of the product.

...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read MoreIf using common galvanized barbed wire due to the influence of climate and environment, will accelerate the corrosion rate of barbed wire lower utilization rate, so use stainless steel barbed wire in coastal areas is the best choice, if it is the environment is dirty it is recommended to use stainless steel barbed wire of nickel content in the highest 316 l, so that you can extend the service life, greatly enhance the protective effect.

1 1 2 ring shank coil nails...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read MoreThe most obvious gap in a short time is the cross section. Because the hot-dip galvanized barbed rope is surface anticorrosive treatment, there will be rust in the cross section, while the stainless steel barbed rope because the internal raw materials are consistent with the surface raw materials, so there is no such situation.

1 1 2 ring shank coil nails...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read MoreBefore wall plastering, the wall column is connected to the gap construction wire mesh, which can play a certain strengthening and heat preservation effect. The mesh is hung on the interface surface of different grassroots, and the length of each side should meet the requirements of 100mm, so as to prevent shrinkage and cracking caused by different grassroots. Mesh wire diameter can also determine the effect and efficiency of construction, mesh fine laid up convenient soft, high construction efficiency; Of national standard can assure quality, but laid respect is inferior to fine construction fast.

1 1 2 ring shank coil nails...

1 1 2 ring shank coil nails 【1 1 2 ring shank coil nails】

Read More

Popular articles

- Hexagonal cage has a wide range of applications, with the progress of science and technology, has been extended to the major hydraulic engineering, civil engineering. Geotechnical engineering and other projects. In the hydraulic hexagonal cage in the river construction to reach the utility, that is appropriate and the use of hexagonal cage used to fill stone, fixed river, can avoid river erosion bring water and soil loss. In the civil engineering project, the hexagonal cage is considered appropriate and the use of similar particle size volume particle filling, cage between the formation of a mesh wall, which is the stone cage mesh retaining wall.

Post time: 28-09-22- Large hexagonal net called stone cage net, mainly used for mountain preparedness protection, hydraulic construction, etc. Small wire hexagonal net is used as a good material for culture, will twist the hexagonal net in the welding of the iron frame on the hexagonal net welding into chicken cage, pigeon cage, rabbit cage and other cage, hexagonal net is an excellent material for culture with net.

The barbed wire factory will store the blade barbed wire inventory in the appropriate place, because it understands the product characteristics.

Latest articles

-

Electric welding net is also known as external wall insulation wire mesh, galvanized wire, galvanized electric welding net, wire mesh, row welding net, touch welding net, construction net, external wall insulation net, decorative net, wire mesh, square eye mesh, screen mesh, anti-crack mesh. Stainless steel electric welding mesh, is made of high quality stainless steel wire row welding, more acid resistance, alkali resistance, welding firm, beautiful, widely used and so on.

-

-

-

The key and important parts with tensile strength greater than 1034Mpa should be relieved of stress at 200±10℃ for more than 1 hour before plating, and the carburized or surface hardened parts should be relieved of stress at 140±10℃ for more than 5 hours. The cleaning agent used for cleaning shall have no effect on the binding force of the coating and no corrosion on the substrate. Acid activation Acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts without excessive corrosion on the matrix.

-

Post time: 15-07-22 -

Links

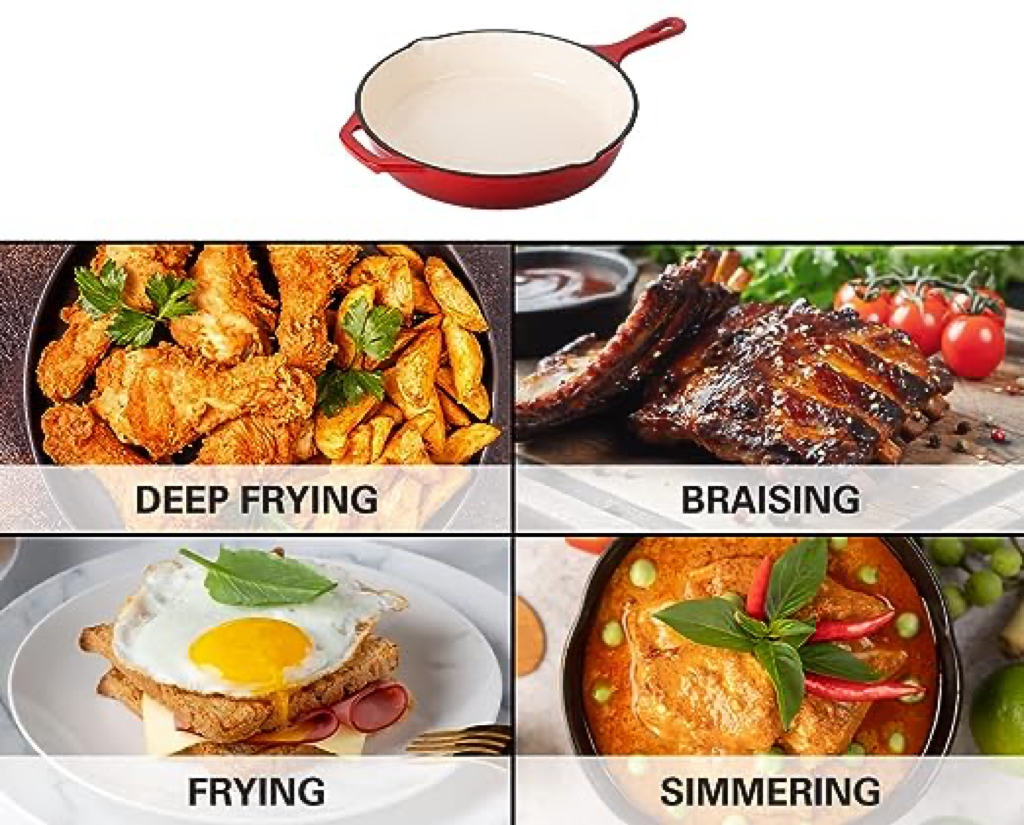

Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor

Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor small enamel pot with lid. Its retro aesthetic, reminiscent of bygone eras, adds a nostalgic touch to modern culinary practices. Whether used as a serving dish or displayed on open shelving, it becomes a decorative element that tells a story of culinary traditions.

small enamel pot with lid. Its retro aesthetic, reminiscent of bygone eras, adds a nostalgic touch to modern culinary practices. Whether used as a serving dish or displayed on open shelving, it becomes a decorative element that tells a story of culinary traditions.When choosing a Dutch oven for outdoor cooking, it's important to consider the type of cooking you'll be doing and the specific features that will best suit your needs. Whether you choose a round cast iron Dutch oven, a camping Dutch oven, or an outdoor cast iron Dutch oven, you can be sure that you are purchasing versatile and reliable cookware that will enhance your outdoor cooking experience. So the next time you’re out camping or on an outdoor adventure, consider bringing along a Dutch oven to up your outdoor cooking game.

Clean Enamel Cookware

Recipes that you plan to grill up fast under high heat, meats that need to be seared, or foods that require constant flipping and stirring with a spatula are most conveniently prepared in a frying pan. The nicely sloped sides of a frying pan also make it possible to toss up a small portion of stir-fry. However, to achieve a perfect finish on this type of shallowly fried dish, a bowl-shaped Wok works best.

There are a few tips to remember when cooking with a cast iron Dutch oven. First, it's important to season your Dutch oven properly before use to create a nonstick surface and prevent rust. Additionally, using gentle heat and avoiding sudden temperature changes can help extend the life of your Dutch oven and prevent cracking.

enamel cooking ware.

What’s Cooking?

cast iron griddle for camp stove. From bacon and eggs in the morning to grilled cheese sandwiches for lunch, to fajitas for dinner, a cast iron griddle can handle it all. You can also use it to cook foods that you wouldn't normally think to cook on a griddle, such as pizza or stir-fry.

Durability and Longevity: Big black cast iron skillets are built to last a lifetime and beyond. With proper care and maintenance, they become seasoned over time, developing a natural non-stick surface that improves with use.

Use Sizzling Hot Plate Benefits

In conclusion, enameled cast iron cookware sets offer a perfect combination of functionality, durability, and aesthetic appeal. Whether used for cooking, baking, or stylish presentation at the dining table, these versatile culinary tools enhance the cooking experience and add a touch of elegance to any kitchen.

outdoor griddle cast iron. It transforms your outdoor kitchen into a bustling hub of culinary creativity, where family and friends can gather around, watch their meals being prepared, and share stories under the open sky.

outdoor griddle cast iron. It transforms your outdoor kitchen into a bustling hub of culinary creativity, where family and friends can gather around, watch their meals being prepared, and share stories under the open sky.Pans are an essential tool in any kitchen, but with so many options available, it can be overwhelming to determine their uses and which ones are the best fit. The various sizes, shapes, and coatings can make it difficult to choose.

Because of its wide base, a sauté pan is significantly heavier than the equivalent skillet, often necessitating the addition of a helper handle on the opposite side of the main handle to facilitate lifting and moving. While this weight is no problem when the pan is sitting still on the stovetop or in the oven, the lighter weight of a skillet makes it superior for shaking and stirring to promote even cooking of vegetables or pieces of chopped meat.

Again, the straight sides of a sauté pan allow you to fit a higher volume of liquid into the same amount of oven space. Straight sides also make the liquid less likely to splash out as you move the pan around or transfer it into and out of the oven. It also allows the lid to fit more tightly, minimizing evaporation. This extra volume is a great boon when you're performing tasks like shallow-frying a pan full of meatballs in a half inch of oil, or braising a dozen chicken thighs in white wine.