framed welded wire mesh panel

Latest articles

framed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read More

framed welded wire mesh panelMagnetic test method is the original common difference between austenitic stainless steel and ferritic stainless steel simple way, austenitic stainless steel is wrong magnetic steel, but after cold processing under large pressure will have a slight magnetic; But pure chrome steel and low alloy steel are strong magnetic steel.

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read More

framed welded wire mesh panel

Post time: 29-12-22...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read MoreA. When the thickness of the plating is 3-4 mm, the zinc adhesion should be less than 460g/m, that is, the average thickness of the zinc layer is not less than 65 microns.

framed welded wire mesh panel...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read Moreframed welded wire mesh panel

...

framed welded wire mesh panel 【framed welded wire mesh panel】

Read More

Popular articles

- 1. Choose according to your dog’s size

Post time: 25-05-23- Generally speaking, in dry main gas and indoor use, the thickness of galvanized coating is only 6-12μm, but under poor environmental conditions, the thickness of galvanized coating is 20μm, can reach 50μm. Therefore, environmental factors should be considered when choosing the thickness of galvanized layer. Galvanized layer after passivation treatment, can naturally form a layer of bright, beautiful color passivation film, can obviously improve its protective function, decorative.

3, reduce the bivalent iron ion in the plating aid used for hot plating wire, reduce the formation of zinc slag

Latest articles

-

-

-

-

As we all know, the use of hexagonal net for protection can protect the natural environment while protecting the bridge, which can not only green the ecological environment, but also prevent soil erosion.

-

Hot dip galvanizing is a kind of external treatment technology in the production of fasteners. The common varieties of hot dip galvanizing fasteners are electric galvanizing, powder galvanizing, mechanical galvanizing and hot dip galvanizing. Wire factory according to different requirements of customers for fasteners, different hot-dip galvanized surface treatment. Galvanized layer and steel is a metallurgical connection, become a part of the steel surface, so the durability of the coating is more reliable.

-

Dark green plastic-coated barbed cords are occasionally used on high-speed trains, but they are also used in small quantities.

Brushed Cotton

Research and development in textiles have also witnessed breakthroughs. Textiles incorporating nanotechnology demonstrate outstanding properties in warmth, breathability, and other aspects, offering consumers a more comfortable wearing experience. Simultaneously, the development of smart textiles, embedding sensors into clothing, allows real-time monitoring of individuals' health conditions, opening new possibilities for health management.

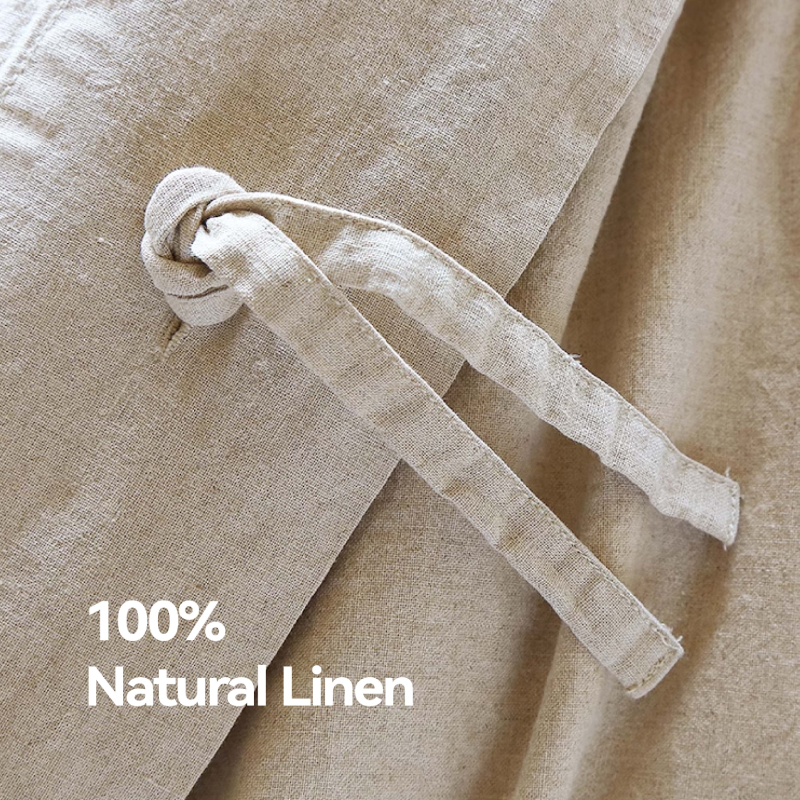

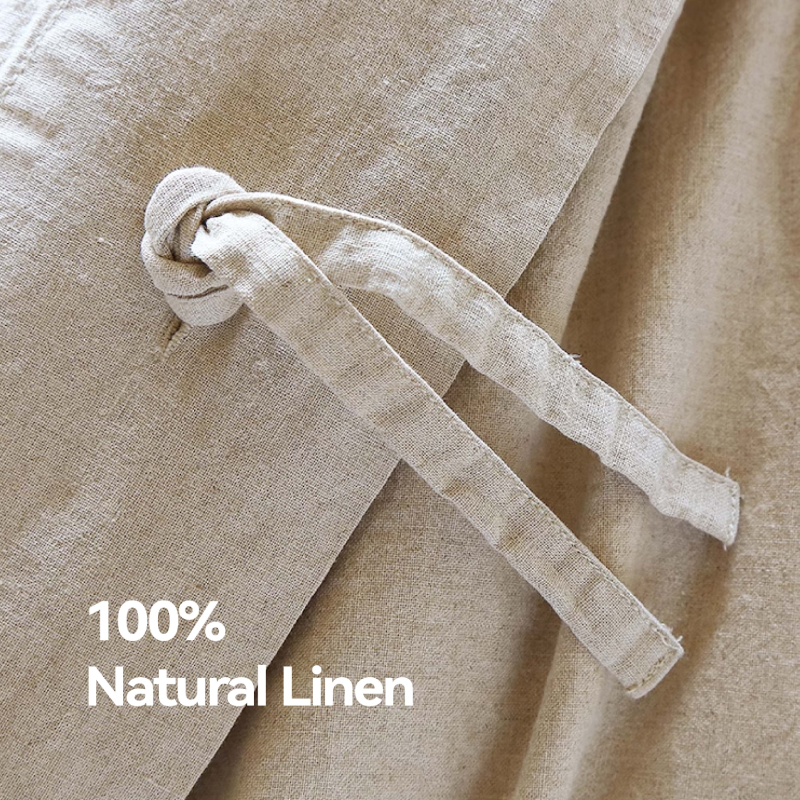

However, if you prefer a cooler sleep environment, you may want to consider materials like bamboo or linen, which have natural cooling properties However, if you prefer a cooler sleep environment, you may want to consider materials like bamboo or linen, which have natural cooling properties

However, if you prefer a cooler sleep environment, you may want to consider materials like bamboo or linen, which have natural cooling properties However, if you prefer a cooler sleep environment, you may want to consider materials like bamboo or linen, which have natural cooling properties choosing sheets. Additionally, silk sheets offer a luxurious feel and are known for their smooth texture, but they can be more expensive than other options.

choosing sheets. Additionally, silk sheets offer a luxurious feel and are known for their smooth texture, but they can be more expensive than other options. highest rated down alternative comforter. A comforter that is too small will not provide adequate coverage, while one that is too heavy may feel stifling and uncomfortable. It's important to find a comforter that is the right size for your bed and has the perfect weight for your sleeping preferences.

highest rated down alternative comforter. A comforter that is too small will not provide adequate coverage, while one that is too heavy may feel stifling and uncomfortable. It's important to find a comforter that is the right size for your bed and has the perfect weight for your sleeping preferences. long waffle robe womens. Patch pockets add convenience without detracting from the overall aesthetic, allowing you to carry small essentials or simply enjoy the comfort of having your hands nestled within the folds of the fabric.

long waffle robe womens. Patch pockets add convenience without detracting from the overall aesthetic, allowing you to carry small essentials or simply enjoy the comfort of having your hands nestled within the folds of the fabric. Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover

Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs.

comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs. To extend the life of your duvet insert, it's important to use a duvet cover to protect it from dust, dirt, and spills To extend the life of your duvet insert, it's important to use a duvet cover to protect it from dust, dirt, and spills

To extend the life of your duvet insert, it's important to use a duvet cover to protect it from dust, dirt, and spills To extend the life of your duvet insert, it's important to use a duvet cover to protect it from dust, dirt, and spills down feather duvet insert.

down feather duvet insert. They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses

They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses what are terry cloth towels. From small washcloths to large bath towels, terry cloth towels can be used for drying off after a shower, wiping down countertops, cleaning up spills, or even for wrapping around the body at the beach or pool.

what are terry cloth towels. From small washcloths to large bath towels, terry cloth towels can be used for drying off after a shower, wiping down countertops, cleaning up spills, or even for wrapping around the body at the beach or pool.In recent years, microfiber sheets have gained popularity due to their soft texture and affordable price. However, microfiber sheets are some common concerns and misconceptions about microfiber sheets that need to be addressed.

They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste

They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste hotel sheet company. This dedication to environmental responsibility aligns with the growing global consciousness, appealing to hotels that value sustainability as part of their brand ethos.

hotel sheet company. This dedication to environmental responsibility aligns with the growing global consciousness, appealing to hotels that value sustainability as part of their brand ethos. This means that you can say goodbye to soggy, damp towels that take forever to dry and hello to fluffy, soft towels that leave you feeling refreshed and rejuvenated This means that you can say goodbye to soggy, damp towels that take forever to dry and hello to fluffy, soft towels that leave you feeling refreshed and rejuvenated

This means that you can say goodbye to soggy, damp towels that take forever to dry and hello to fluffy, soft towels that leave you feeling refreshed and rejuvenated This means that you can say goodbye to soggy, damp towels that take forever to dry and hello to fluffy, soft towels that leave you feeling refreshed and rejuvenated full size towel. Whether you're using them to dry off after a swim or to wrap around yourself after a long day, full-size towels provide the ultimate in comfort and absorbency.

full size towel. Whether you're using them to dry off after a swim or to wrap around yourself after a long day, full-size towels provide the ultimate in comfort and absorbency. Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover

Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs.

comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs.However, these are not to be confused with Belgium or French Flax Linen. Manufacturers created this subtle distinction to determine how much of the linen production process is done in its country of origin.