cold dip gi wire

Latest articles

cold dip gi wire

...

cold dip gi wire 【cold dip gi wire】

Read More

cold dip gi wireAnd high quality data is constrained by production cost and production conditions, so some welding mesh manufacturers do not meet this requirement, natural in this case, there is no way to improve the strength of the product. In addition to the data, there is the production process, even if it is the best data, but the manufacturer does not meet the production process requirements in the welding, it will also form the product under high pressure welding, so this is also a decline in strength, the process conditions of different manufacturers are also very different, so it forms the market above the product has a difference in strength.

...

cold dip gi wire 【cold dip gi wire】

Read Morecold dip gi wire

...

cold dip gi wire 【cold dip gi wire】

Read MoreIn summary, as a commonly used anticorrosive material, electrogalvanized wire has good corrosion resistance. Its corrosion resistance mainly depends on the thickness, uniformity and structure of zinc layer, substrate material and environmental conditions and other factors. Through reasonable electroplating process and material selection, the corrosion resistance of electrogalvanized wire can be improved and its service life can be extended.

cold dip gi wire...

cold dip gi wire 【cold dip gi wire】

Read Morecold dip gi wire

...

cold dip gi wire 【cold dip gi wire】

Read Morecold dip gi wire

...

cold dip gi wire 【cold dip gi wire】

Read Morecold dip gi wire

...

cold dip gi wire 【cold dip gi wire】

Read More

cold dip gi wire

Post time: 09-10-22...

cold dip gi wire 【cold dip gi wire】

Read MoreThe application range of small hexagonal mesh is also relatively wide, can be used for building wall fixed insulation layer, pipeline, boiler fixed heat preservation, decoration and other fields.

cold dip gi wire...

cold dip gi wire 【cold dip gi wire】

Read More

cold dip gi wireIn the process of composite plating, it is necessary to stir the plating solution to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc. In the process of production, the acid activation solution can remove the corrosion products and oxide film on the surface of low carbon steel wire without excessive corrosion on the matrix. Galvanized wire can be used zincate galvanized or chloride galvanized and other processes, appropriate additives should be used to obtain the coating required by the standards of low carbon steel wire.

...

cold dip gi wire 【cold dip gi wire】

Read More

Popular articles

Latest articles

-

-

Large coil galvanized wire in the zinc immersion distance debugging, keep the original speed unchanged, according to t= KD to determine the zinc immersion time (1), where: t is the zinc immersion time is constant, take 4-7D is the diameter of steel wire mm, and then estimate the zinc immersion distance. By adjusting the zinc dip distance, the zinc dip time of steel wire of various specifications can be shortened by 5s on average. In this way, the zinc consumption per ton of steel wire decreases from 61kg to 59.4kg.

-

-

-

-

Post time: 01-02-23

5. Pfaff Ambition 610 Renowned for its IDT technology that ensures even feeding from both the top and bottom, this machine is perfect for handling challenging fabrics. With 130 built-in stitches and a large sewing area, it provides excellent functionality for serious sewists.

The Art and Efficiency of Swing Needle Sewing Machines

Key Features to Look For

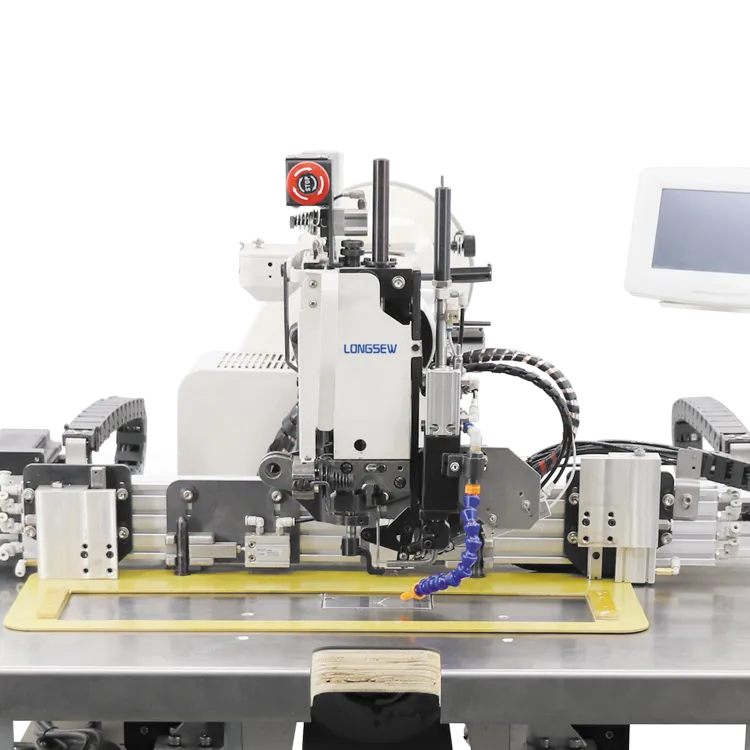

1. The thick material sewing machine is suitable for sewing shoes, sofas, container bags, safety belts, tents, leather, and other extremely thick materials.