sheetrock screws for hanging pictures

Latest articles

Determine the size of the dog cage based on the dog’s actual adult size. In general, the cage should be three times the size of the dog’s body and give him enough room to turn around and so on.

sheetrock screws for hanging pictures...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read MoreHexagonal mesh is also known as twisting mesh, thermal insulation net, soft edge net. It is made of single – layer mesh. Its mesh, mesh wire, galvanized and PVC film properties and the same as the cage. This product can be different shapes and sizes of the block stone into the alloy net to form a flexible whole, through lifting, car, shipping to the place, the alloy net connected to each other into a larger whole, construction throwing convenient, fast, good economic performance.

sheetrock screws for hanging pictures...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read MoreGenerally speaking, it is necessary to install thorn rope in pasture, which is simpler and saves time and effort. It is better managed because it is full of spikes that keep livestock away from the barbed fence.

sheetrock screws for hanging pictures...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read Moresheetrock screws for hanging pictures

...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read More

sheetrock screws for hanging picturesFor example, in gray iron, its carbon exists in iron ore in the form of graphite, the crack is often gray, soft and tough, simple filter cutting, suitable for casting. In the white iron, the carbon and iron are combined to form iron carbide, the crack appears white, the quality is very strong and brittle, and it is the material of malleable steel. Alloying grade is composed of various alloying elements with different composition and structure.

...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read More

sheetrock screws for hanging pictures

Post time: 22-02-23...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read Moresheetrock screws for hanging pictures

...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read Moresheetrock screws for hanging pictures

...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read Moresheetrock screws for hanging pictures

...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read More3. Straightening and cutting: straighten and cut the cold galvanized wire after drying to reach the set size and length.

sheetrock screws for hanging pictures...

sheetrock screws for hanging pictures 【sheetrock screws for hanging pictures】

Read More

Popular articles

1, the blade barbed rope damage should be timely corrected

- Zinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is the length of the distance between the lead screw on the zinc pot and the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire galvanized, is an aspect of maintaining the uniformity of zinc layer.

Post time: 23-12-22

Latest articles

-

Post time: 18-11-22 -

-

Because zinc layer corrosion resistance, can be applied to all kinds of environment, use is also very convenient, has been more popular hardware products. Galvanized iron wire should pay special attention to the acyl washing, to slowly put into the container, to prevent acid sputtering on the body, and prohibit the water into the water, so that it is easy to let the acid out, to learn to handle gently, stacking should also be firm and neat. It can be widely used in architecture, handicrafts and other daily civilian applications.

-

-

After a long time of use, it will not rust after the corrosion layer on the surface of the hot-dip galvanized barbed wire has problems, because the material inside the stainless steel barbed wire is the same as the material on the surface.

-

Large coil galvanized wire is made of high quality low carbon steel wire rod processing, is made of high quality low carbon steel, after drawing molding, pickling rust removal, high temperature annealing, hot dip galvanized. Cooling process and other processing. Galvanized wire is divided into hot galvanized wire and cold galvanized wire. Galvanized wire in the process of smelting there are a lot of need to pay more attention to the place, galvanized wire products in the manufacturing process will experience a lot of process, of which the following galvanized wire annealing is a very important step, this step to the nature of galvanized wire has brought a lot of help.

Links

3. 16 x 16 inches This size is ideal for moderate access requirements, often suited for utility areas where larger components may need attention.

1. Moisture Management One of the primary benefits of waterproof exterior access panels is their ability to manage moisture effectively. Buildings in areas with high humidity or heavy rainfall are at an increased risk of mold growth, structural damage, and electrical hazards due to water intrusion. By installing waterproof access panels, property owners can safeguard their buildings against these risks.

In terms of safety, an attic access door should comply with local building codes, especially if the attic is used as a living space. Adequate ventilation is also crucial to prevent moisture build-up, which can lead to mold and structural damage. It’s wise to ensure that any access points are well-constructed and easy to operate, improving safety for all who may need to enter.

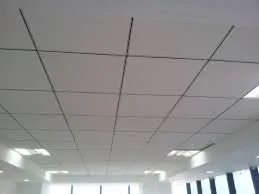

Ceiling grid bars are integral components in modern architectural design, particularly within the realm of suspended ceilings. They serve both functional and aesthetic purposes, enabling buildings to achieve a clean, organized, and efficient design while also providing essential structural support. This article will delve into the details of ceiling grid bars, exploring their types, applications, benefits, and installation processes.

Conclusion

4. Facilitation of Inspections Regular inspections are crucial for maintaining the integrity of a building's infrastructure. Ceiling access panels make it convenient for inspectors to conduct thorough evaluations and ensure that all systems are functioning properly. This proactive approach can help in identifying problems early, thus avoiding costly repairs in the future.

3. Acoustic Access Hatches In environments where noise control is vital, acoustic access hatches help maintain sound insulation while still allowing for necessary access. These hatches are designed to minimize noise transmission and can be particularly useful in theaters, studios, and conference rooms.

Aesthetic Appeal

Benefits of Access Panels in Ceilings

The Importance of Proper Installation

1. Maintenance and Repair Accessibility One of the most significant advantages of a ceiling access panel is that it grants technicians quick access to vital systems. Whether it's an HVAC duct, electrical wiring, or plumbing lines, a 30x30 panel provides ample space for repairs or adjustments, thereby minimizing service disruption.

What is a 600x600 Ceiling Access Hatch?

Another significant advantage of frameless access panels is their cost-effectiveness. While some may assume that their sleek design and modern appearance come at a premium, frameless panels often provide substantial savings in the long run. Their easy installation reduces labor costs, while their durable materials ensure that they withstand the test of time, minimizing the need for replacements or repairs. Additionally, by facilitating efficient maintenance of concealed systems, these panels can help prevent costly emergencies and disruptions.

Aesthetic Appeal