heavy duty aluminum screen

Latest articles

③ The galvanized iron wire shall not be damaged when it is tightened.

heavy duty aluminum screen...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read Moreheavy duty aluminum screen

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read More

heavy duty aluminum screenHot dip galvanized coating is also relatively thick, but there is an uneven situation, for example, the thickness of the thin is only 45 microns, thick can reach 300 microns or even thicker, the color of this product is relatively dark. There is also a lot of zinc consumed in the production process. Zinc will form an infiltration layer with the metal. Its advantage is that it has good corrosion resistance. Electrogalvanizing, it is through the plating tank in the zinc one-way plating on the outside of the metal products, this way of making products is relatively slow, but its thickness is more uniform.

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read More

heavy duty aluminum screenNow most people buy barbed rope choose blade barbed rope, why is this? From the material blade barbed wire technology blade gill net is made of hot-dip galvanized steel plate or stainless steel sheet stamped out sharp knife sheet, high tension galvanized steel wire or blade barbed wire stainless steel wire as core wire combination of the resistance device. Because the gill net shape is not easy to contact, so it can achieve excellent protective barrier effect. The primary raw materials of products are galvanized sheet and stainless steel plate.

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read MoreDue to the implementation of the grassland contract operation obligation system, herdsmen have a high capacity to strengthen and raise their stainless steel barbed rope fence net in grassland pastoral areas, forming the phenomenon of high density and high height of stainless steel barbed rope fence net in grassland pastoral areas, which is destructive and even destructive to the survival of wild animals.

heavy duty aluminum screen...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read Moreheavy duty aluminum screen

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read More

heavy duty aluminum screenWire mesh production of general selection of low carbon wire, after fine and accurate active welding equipment processing, the selection of galvanized process surface treatment. After the completion of the product, the net surface is smooth and regular, good integrity, strong and consolidated, even if part of the choice or pressure will not appear lax phenomenon.

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read Moreheavy duty aluminum screen

...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read More

heavy duty aluminum screen

Post time: 03-04-23...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read MoreLarge rolls of galvanized wire products are widely used because of its anti-rust and anti-corrosion effect, because zinc has a great protective effect on the appearance of the product, so it greatly improves the role and characteristics of the product itself, which also promotes the promotion of the application of the product. The characteristics of galvanized wire products on galvanized wire products are the factors that determine many characteristics of galvanized wire products.

heavy duty aluminum screen...

heavy duty aluminum screen 【heavy duty aluminum screen】

Read More

Popular articles

Post time: 15-07-22After annealing, iron wire will become softer and more flexible. Iron is a more active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements in dry air, its production cost is low, the use and scale is relatively wide, better protective function, so it is an important material for steel parts used in strict working environment.

- Galvanized wire to galvanized evenly, a body is now its cross section, the second is the longitudinal uniformity. In the actual operation process, such as the jitter of steel wire, the surface scum in the plating pot and other reasons will cause the accumulation of galvanized layer on the surface of galvanized wire, and efforts should be made to solve the problem.

Latest articles

-

The above are the three major advantages of the positive and negative twisting barbed wire, mainly including durability, high cost performance, and beautiful appearance.

-

-

3. The transport, storage and use of the binder of galvanized wire mesh should adopt safety and fire prevention methods according to the relevant regulations, so as to be safer.

-

On the highway, barbed rope protection net is generally to prevent people and animals from crossing the highway at will, so as not to interfere with driving and reduce accidents, as well as effectively prevent illegal occupation of road land and other issues of traffic safety facilities. There are many forms of barbed rope protective nets, commonly used metal, woven net, barbed wire and often green gracilaria. Metal braided net is set in crowded areas, barbed wire is used in areas with few people and animals, and the structure of hedges and barbed wire is used in toll stations and service areas. In the past two years, considering the beauty of the problem, in the Pearl River Delta region of some highways with fruit plastic spot welding network (usually said guardrail network), this barbed rope protection network is more good-looking, durable, the overall effect is good, but the construction requirements are higher, more expensive. General sections should not be used, in the city center, scenic spots or strong requirements for beautiful sections can be used.

-

-

Post time: 17-04-23

Links

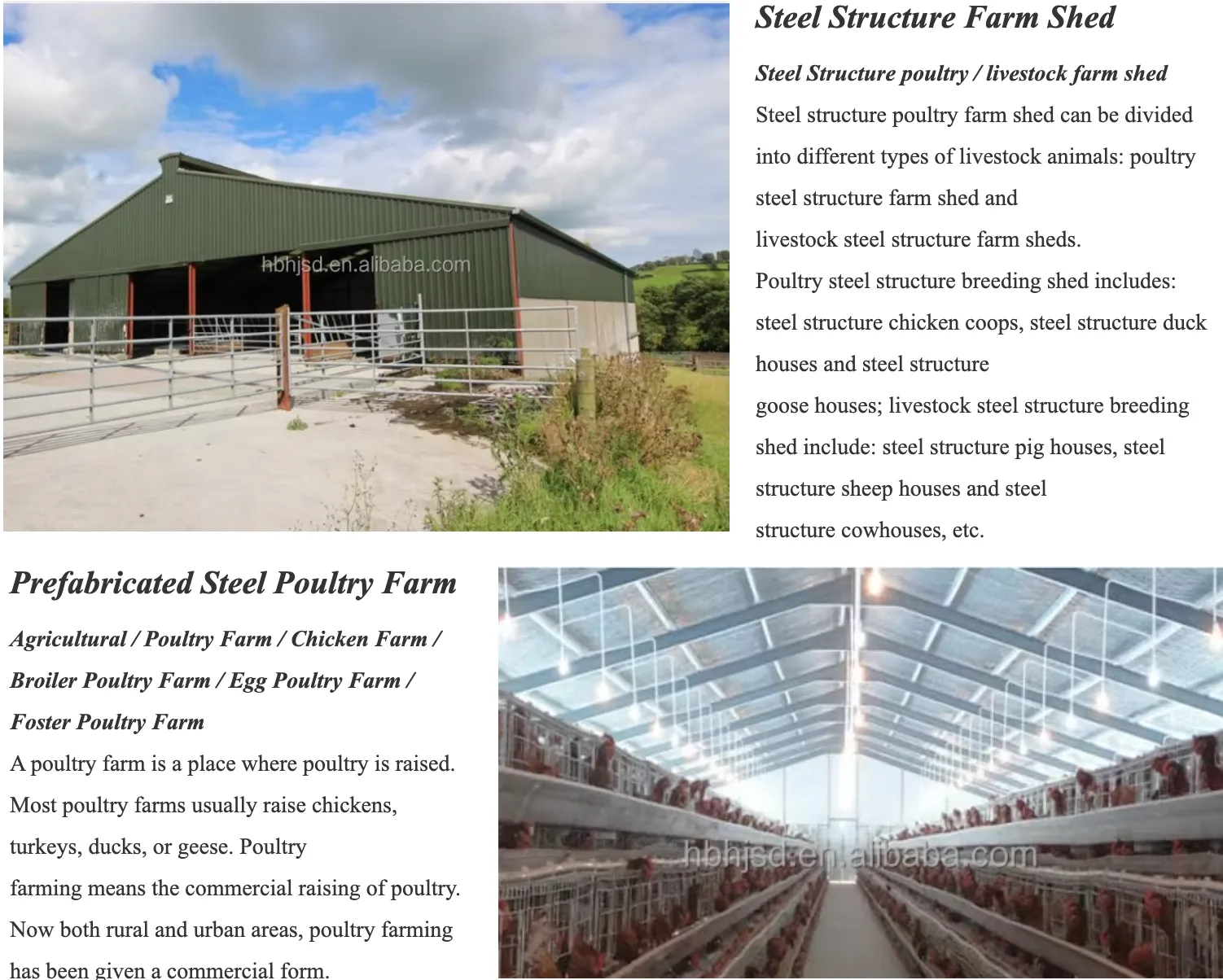

The Significance of Portal Frame Warehouses in Modern Construction

Metal agricultural sheds are primarily constructed from steel or aluminum, materials known for their durability and strength. Unlike wooden sheds, metal structures are not susceptible to rot, pests, or harsh weather conditions. This resilience ensures that farmers can rely on their sheds for longer periods, minimizing the need for frequent repairs or replacements. In an era where cost-effectiveness is paramount, investing in metal sheds could lead to substantial savings over time.

Materials are a significant portion of the total cost of a steel workshop. The type of steel used, the quality of insulation, and other construction materials greatly affect the overall expenditure. Steel prices can fluctuate based on market conditions, so it is critical to monitor these prices when planning a budget. Additionally, using eco-friendly or high-grade materials may increase upfront costs but could reduce long-term operational costs, such as energy bills and maintenance.

If your warehouse plan is submitted to a steel structure manufacturer company, the building will be pre-designed and manufactured by experts. It makes the entire process from start to finish more economical, resulting in ready-made steel construction components shipped directly to the worksite.

Metal buildings are renowned for their strength and durability. A 30x40 prefab metal building is designed to withstand harsh weather conditions, including snow, high winds, and heavy rain. Unlike wood, metal is not susceptible to rot, termites, or mold, which decreases the need for high maintenance. When properly installed and maintained, a metal building can last for several decades, providing a solid return on investment. This longevity is a critical consideration for individuals and businesses looking to maximize the lifespan of their structures.

Steel Farm Sheds A Durable and Versatile Solution for Agricultural Needs

Low Maintenance Requirements

Hangers The Backbone of Aircraft Maintenance

Conclusion

Despite its compact footprint, a 6x8 metal shed offers a surprising amount of storage capacity. The interior can be customized with shelves, hooks, and organizational systems, allowing owners to make the most of the available space. The shed can serve as a dedicated workspace for DIY projects, a gardening station, or simply a place to store tools and equipment securely.

shed 6x8 metal

One of the best features of an 8ft x 8ft metal shed is its versatility. Homeowners can use it for various purposes beyond mere storage. For instance, it can be transformed into a workshop for DIY projects, a potting shed for gardening enthusiasts, or even a small hobby space for arts and crafts. The adaptability of this shed means it can evolve with your needs over time, providing continual value as your storage requirements change.

The first step in building your garage workshop is to carefully plan your space. Assess the size of your garage and determine how much room you need for your workshop. Consider what activities you plan to engage in—woodworking, metalworking, automotive repair, or arts and crafts—and tailor the dimensions of your workshop accordingly. Ideally, your workshop should have enough space for essential tools, equipment, and ample room for movement.

Durability and Strength

3. Cost: The structure’s cost must be considered when designing the warehouse.

Investing in a metal shed can significantly enhance your storage capabilities while adding value to your property. By considering size, material, assembly, ventilation, and flooring options, you can make an informed decision. As you explore your options, remember to check customer reviews and warranties to ensure you purchase a reliable product that meets your expectations. With the right metal shed, you will have a functional and aesthetically pleasing storage solution that lasts for years to come.

The Advantages of Steel Beam Construction

Steel structure warehouse buildings usually consist of steel beams, columns, steel trusses, and other components.

The various components or parts are connected by welding, bolting, or rivets.

1. Main structure

The main structure includes steel columns and beams, which are primary load-bearing structures. It is usually processed from steel plate or section steel to bear the entire building itself and external loads. The main structure adopts Q345B steel.

2. Substructure

Made of thin-walled steel, such as purlins, wall girts, and bracing. The secondary structure helps the main structure and transfers the main structure’s load to the foundation to stabilize the entire building.

3. Roof and walls

The roof and wall adopt corrugated single color sheets and sandwich panels, which overlap each other during the installation process so that the building forms a closed structure.

4. Bolt

Used to fix various components. Bolt connection can reduce on-site welding, making the installation of steel structure easier and faster.

In conclusion, steel buildings for sale present a valuable investment for individuals and businesses alike. With their durability, versatility, and potential for cost savings, these structures cater to a wide range of applications. By understanding the pricing dynamics and thoroughly researching the available options, you can make an informed decision that best suits your project requirements. Whether you are looking to expand your business or create a personal space, a steel building can be an ideal solution, providing both functionality and longevity.

3. Energy Efficiency Modern prefab buildings, including the 30x30 model, are often designed with energy efficiency in mind. Many come equipped with advanced insulation, energy-efficient windows, and eco-friendly materials. As a result, they provide long-term savings on energy costs while reducing the environmental footprint.

Customization options can also significantly impact the final cost. Adding insulation, premium finishes, or specialized functionality will increase the overall price. It's essential for buyers to assess their needs and budget before making a purchase.

One of the standout features of metal garages is their durability. Constructed from high-quality steel, these garages can withstand severe weather conditions, including heavy snow, torrential rain, and strong winds. Unlike wooden garages, which can warp or succumb to termite infestations, metal structures maintain their integrity over time. This means that your vehicle will remain safe and secure inside regardless of external conditions, reducing the risk of damage from falling branches, hail, or flooding.

When shopping for an insulated metal shed, there are several factors to keep in mind

insulated metal sheds for sale

A 12x10 metal shed is more than just a storage solution; it is a versatile addition to your outdoor space that enhances organization, security, and functionality. With their durability and varying applications, these sheds cater to a range of needs—making them a smart investment for homeowners. By choosing a metal shed, you can enjoy a clutter-free yard, peace of mind regarding security, and the flexibility to adapt your space as your lifestyle changes. If you’re looking to enhance your outdoor area, a 12x10 metal shed may be the perfect solution for you.

Sustainability and Environmental Benefits

Security is a primary concern for anyone investing in a storage solution. Metal sheds often come equipped with advanced locking mechanisms, making it difficult for intruders to gain access. Additionally, the robust nature of metal itself adds an extra layer of security, as it is much harder to breach than wood or plastic. For businesses that store valuable equipment or tools, a quality metal shed provides peace of mind that their assets are protected.

The Importance of Warehouse Building Use Maximizing Efficiency and Functionality

Exploring Large Metal Storage Sheds The Ultimate Solution for Your Storage Needs

As farming practices embrace technology, barns are evolving into sophisticated hubs of innovation. Smart barns equipped with sensors and IoT (Internet of Things) devices allow farmers to monitor livestock health, assess feed storage levels, and manage environmental conditions from their smartphones or computers. This data-driven approach enables farmers to make informed decisions that can lead to increased productivity and reduced waste. Moreover, automated systems for feeding, milking, and monitoring animal health streamline operations, allowing farmers to focus on more strategic aspects of farm management.

The Metal Garage 2 project began on a crisp autumn afternoon when Jake, the unofficial leader of the group, gathered his friends for a brainstorming session. With the sun setting behind the mountains, casting a warm orange glow through the windows, he began sketching out his vision for the garage’s revival. “This is more than just fixing cars,” he proclaimed, enthusiasm lighting up his eyes. “It’s about creating a community space – an arts hub for music, art, and all things creative!”

The Red Iron Barn A Symbol of Tradition and Resilience

Easy Assembly and Customization

In addition, the construction time for metal garages is considerably reduced compared to traditional buildings. Pre-engineered metal building kits are available, allowing for quick assembly and reducing labor costs. Many providers offer easy-to-follow instructions that enable savvy DIY enthusiasts to undertake the installation themselves. This speed and efficiency in construction mean that owners can enjoy their new space sooner rather than later.

Regional Variations in Pricing

2. Low Maintenance Steel pole barns require significantly less maintenance compared to wooden structures. They are resistant to pests like termites and do not suffer from issues like rot or mold. A simple wash with water usually suffices to keep the exterior looking fresh.

Steel Structure Warehouses

1. Durability and Longevity One of the most appealing features of metal barns is their robustness. Constructed primarily from steel, they are designed to withstand harsh weather conditions, including heavy snow, strong winds, and rain. Unlike wooden structures that may succumb to rot, pests, or fire, metal barns can last for decades with minimal maintenance.

Key Considerations in Warehouse Design

Incorporating scalability into the initial design allows for future expansion, ensuring that the warehouse can grow in tandem with the business, thereby avoiding costly relocations or extensive renovations.

Another significant advantage of prefab metal buildings is their durability. Steel structures are resistant to many of the common issues that plague traditional buildings, such as termites, rot, and severe weather conditions. This resilience translates to lower maintenance costs over the lifespan of the building. Regular upkeep typically involves simple inspections and occasional cleaning, promoting long-term savings for property owners.

Moreover, the quick and easy installation process associated with metal garages adds to their appeal. Most metal structures can be pre-fabricated and assembled on-site in a fraction of the time required for conventional construction. This means that homeowners can have their garage built and ready for use in a much shorter timeframe, eliminating the lengthy wait associated with traditional construction projects.

The modular nature of prefabricated industrial steel buildings allows for rapid on-site assembly. Once the components arrive at the construction site, they can be quickly bolted or welded together. This eliminates the need for extensive on-site fabrication, which can be time-consuming and prone to errors.