heavy duty wire mesh screen

Latest articles

heavy duty wire mesh screen

Post time: 28-04-22...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read More

heavy duty wire mesh screen

Post time: 10-11-22...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read Moreheavy duty wire mesh screen

...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read More

heavy duty wire mesh screen

Post time: 19-08-22...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read More

heavy duty wire mesh screen

Post time: 20-10-22...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read MoreGalvanized iron wire is divided into hot galvanized wire and cold galvanized wire, the use of low carbon steel wire processing, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. Good toughness and elasticity, zinc content can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Galvanized iron wire can be cut off the tie wire used in the building, the length of 20cm 30cm 40cm, can be cut off according to requirements.

heavy duty wire mesh screen...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read MoreBecause they are afraid of the rain, so there is no need to say more, and the surface of the packaging is more afraid of the sun, so it is not recommended to prevent the outdoor blade thorn rope will cause the woven bag to become ineffective, resulting in the internal blade thorn rope exposed to affect the later use.

heavy duty wire mesh screen...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read MoreHook net use value is still very high, has a very good sex, and its manufacturing concise generous, beautiful, not in high temperature will fade, you can save a sum of maintenance costs, but also according to the different needs of the site to change the shape, to meet the needs of the site.

heavy duty wire mesh screen...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read Moreheavy duty wire mesh screen

...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read MoreWhen in use, wrap into a roll cage. First, its ventilation is good, conducive to the air drying of corn; Second, occupy a small space, convenient drying, good air permeability, light transmission; Third, beautiful and strong, reusable, cost-effective. And in the storage process, it is easy to cover in rain and snow weather to avoid the deterioration of corn mold.

heavy duty wire mesh screen...

heavy duty wire mesh screen 【heavy duty wire mesh screen】

Read More

Popular articles

Razor wire, also known as razor wire and razor net, is a new type of protective net. Blade barbed wire has beautiful, economic and practical, good anti-resistance effect, convenient construction and other excellent characteristics, at present, blade barbed wire has been widely used in many countries of industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention houses, government buildings and other countries of the security facilities.

Post time: 13-04-23- The main raw materials of blade barbed wire are galvanized wire and galvanized sheet. Because the price of galvanized sheet is more expensive than galvanized wire, it is directly reflected in the price of blade barbed wire sales. There is also the difference in processing technology also leads to the difference in the price of the blade barbed rope. The traditional barbed rope is mechanically twisted, with relatively small labor consumption and high production efficiency. But the blade barbed rope is after the second mechanical processing in the artificial processing operations to appear. Therefore, there is a big gap between labor force and production efficiency. These factors lead to the price of the blade barbed rope is more expensive main factors.

- 3. For temporary protection, breeding chickens and ducklings, etc., it is recommended that you choose products with a wire diameter of 2mm.

Latest articles

-

In order to pack and bind galvanized wire in the surface of the sedimentary layer to local removal of surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is formed when soap and surfactants such as saponified fats are brought into the tank. Moderate rates of foam formation may be harmless. Small, homogeneous particles of large denier present in the bath can stabilize the foam layer. Use activated carbon mat to remove surface active substance. Or through filtration to make the foam is not too stable, which are effective measures; Other measures should also be taken to reduce the amount of surfactant introduced. The electroplating speed can be obviously reduced by the addition of organic matter. Although chemical formulations facilitate high deposition rates, the deposition of organic matter does not meet the requirements of coating thickness, so activated carbon can be used to treat the bath.

-

-

-

Post time: 25-10-22 -

Post time: 09-02-23 -

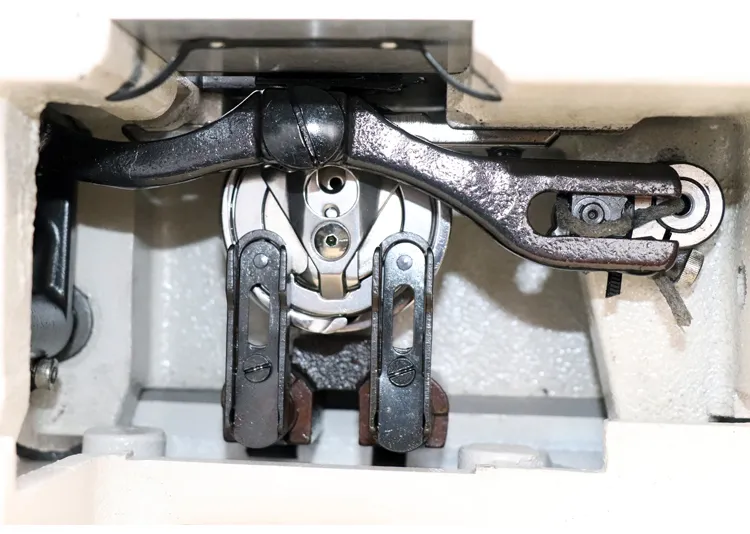

How Does a Lock Stitch Machine Work?

Another advantage is the tactile feedback these machines offer. As craftsmen turn the crank, they develop a sense of connection to their work, allowing them to feel the material they are sewing. This hands-on experience can lead to a higher level of craftsmanship and a greater appreciation for the art of leatherworking. The slow, deliberate pace of hand sewing also encourages mindfulness, allowing artisans to focus on each stitch and detail carefully.

Overall, woven sack sewing machines play a crucial role in the production of woven sacks, providing a fast, efficient, and reliable way to stitch together the durable polypropylene material. These machines are essential for industries that rely on woven sacks for packaging and transportation, ensuring that goods are safely stored and transported in a secure and durable packaging solution.

In conclusion, automatic template sewing machines represent a significant advancement in the textile industry, combining efficiency, accuracy, and creativity. As these machines continue to evolve, they promise to play an increasingly vital role in shaping the future of sewing, both for industrial applications and personal projects. Whether you are a seasoned professional or a novice at the sewing machine, embracing this technology may unlock new possibilities and enhance your sewing experience. As the industry continues to innovate, the potential for even more sophisticated automatic template sewing machines awaits on the horizon, heralding a new era in textile production.

Conclusion

Car mats serve a crucial role in maintaining the cleanliness and aesthetics of vehicles. They not only protect the vehicle's interior from dirt, mud, and spills but also enhance the overall driving experience. For those passionate about customization and craftsmanship, sewing your own car mats can be an enjoyable and rewarding project. With the right knowledge and tools, turning raw materials into stylish, functional car mats becomes an art form that reflects personal style.

4. Time Efficiency By combining the capacity to handle larger projects with the versatility of zigzag stitching, these machines can significantly reduce sewing time. Sewists can complete more projects in less time, making them ideal for both professional use and hobbyists looking to maximize their crafting experience.

Moreover, specialized sewing machine retailers often have a selection of industrial machines and a knowledgeable staff that can help you select the right model to fit your specific needs. Be sure to conduct thorough research, including reading reviews and comparing different models, to ensure you make an informed decision.

A heavy duty basic sewing machine is specially designed to handle a wide range of fabrics, including thick and heavy materials such as denim, canvas, and upholstery fabric. Unlike standard sewing machines, which may struggle with these tougher materials, heavy duty machines come equipped with stronger motors, reinforced structures, and specialized stitching capabilities that make them ideal for demanding sewing projects.