concrete nail material

Latest articles

concrete nail materialGalvanized hook net, is not easy to corrosion, long life protection net. Galvanized hook mesh is durable and easy to install. Wire factory introduction galvanized hook mesh all parts are hot dip galvanized steel to guarantee a 12-year warranty. The frame-structure terminals used to connect the chain links are made of aluminum to maintain the security of free enterprise. The cost of hot-dip galvanizing is low, and the cost of hot-dip galvanizing is lower than that of other anti-rust treatment.

...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read More

concrete nail material

Post time: 04-05-23...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read More3. Before cleaning the cage, put the birds in a safe place, and then clean out the garbage inside the cage. Clean it up with a sweep. Then use a wet rag to clean on site.

concrete nail material...

concrete nail material 【concrete nail material】

Read MoreHot dip galvanizing is the plating of zinc layer on the surface of Angle steel, channel steel and other metals to achieve the appearance of convenience and rust prevention of metal. Hot-dip zinc processing plants use zinc tin solution to prevent corrosion on the workpiece. This new technology can extend the corrosion time by up to five times, which is usually used in outdoor construction. Because the principle of action is not the same, so the role of the workpiece is not the same. The appearance of hot dip zinc plant is only to expand the scope of action.

concrete nail material...

concrete nail material 【concrete nail material】

Read Moreconcrete nail material

...

concrete nail material 【concrete nail material】

Read More

Popular articles

It was designed not only to be easy to install, but also to allow for quick and easy installation in harsh terrain such as cliffs, with little anchorage and little excavation. Based on the characteristics of heavy hexagonal mesh duplex structure, it can withstand the impact of falling rocks even when the steel wire is damaged.

Post time: 19-09-22Greenhouse special electroplating process iron wire blackening solution:

- There are two kinds of electrochemical protection. One is to connect a piece of metal that is slightly more vivid than it. For example, ships and ships will be inlaid with zinc blocks. The second is to connect the negative terminal of the power supply, such as iron and steel river locks are often connected with the negative terminal of the power supply, through the negative terminal. Its methods include: metal cover film such as electroplating, organic coating such as paint, transformation layer such as orchid or black, new elements to change the metal structure.

- In general, the organic matter contained in the galvanized wire can make the plating speed significantly reduced. Although the chemical formulation is conducive to high deposition rate, but the organic matter with the coating thickness can not meet the requirements, so activated carbon can be used to treat the tank liquid. Zinc is a silver-white metal, brittle at room temperature, soluble in acid can also be soluble in alkali, known as amphoteric metal.

Latest articles

-

-

-

-

According to the galvanized iron wire manufacturer, galvanized iron wire is the selection of excellent low carbon steel, through drawing forming, pickling rust removal, high temperature annealing, hot dip galvanized, cooling and other processes. Galvanized iron wire should pay attention to the following points in the use process:

-

-

National standards on the use of wire mesh standards have certain requirements, diameter and mesh size matching use, rather than simply diameter size, on the plaster layer to use is mesh should not be greater than 20×20, diameter is not easy to be less than 1mm, light selection diameter is not much significance, choose 40×40×0.9 and choose 10×10×0.6 wire mesh, Which one is better? 10×10×0.6, I’m afraid.

Links

4. Safety and Compliance Building codes often require specific access points for maintenance of various systems. A drywall ceiling hatch enables compliance with these codes while maintaining an aesthetically pleasing environment. By providing easy access to critical infrastructure, hatches can help prevent safety hazards associated with neglecting necessary maintenance.

4. Cost-Effective Solution Installing access panels can prove to be a cost-effective solution in the long term. By facilitating easy access for routine maintenance, they can help prevent costly repairs that might arise from neglected systems.

1. Location Selection Identify the optimal location for the panel to ensure it allows access to the necessary utilities while maintaining visual appeal.

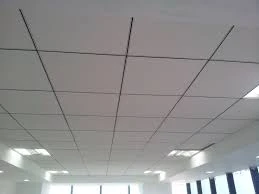

In the realm of interior design and construction, aesthetics and functionality often go hand in hand. One of the essential components of achieving a polished look in commercial and residential spaces is the ceiling. Among the various ceiling options available, drop ceiling tees have emerged as a popular choice for their practicality and versatility. This article explores the significance, benefits, and applications of drop ceiling tees, shedding light on their growing prominence in contemporary architecture.

Micore 300 is widely applicable in various sectors due to its diverse properties. In the construction industry, it is frequently utilized in wall systems, ceilings, and flooring. Its lightweight nature makes it easy to handle and install, facilitating faster project completion than heavier alternatives. Additionally, renovation projects benefit from Micore 300 as it can be applied over existing structures without significant modifications to the supporting elements.

Durability is a critical factor when selecting ceiling materials, and PVC coated gypsum tiles excel in this regard. The PVC layer offers excellent protection against moisture, helping to prevent issues such as warping, mold growth, or degradation that can occur with uncoated gypsum. This makes them an ideal choice for environments with high humidity, including kitchens, bathrooms, and commercial spaces. Moreover, the robust nature of both gypsum and PVC ensures that these tiles can withstand the wear and tear of daily usage, leading to a longer lifespan compared to traditional ceiling materials.