galvanized iron wire manufacturer

Latest articles

galvanized iron wire manufacturer

...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read More

galvanized iron wire manufacturer

Post time: 01-11-22...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read MoreThe wire mesh is finished by fine welding of active welding equipment. The material can be divided into cold drawing wire, hot dip galvanized, cold galvanized, dip plastic and so on. To be used for bridge reinforcement, deck paving, building reinforcement, etc.

galvanized iron wire manufacturer...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read Moregalvanized iron wire manufacturer

...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read MoreSecondly, galvanizing can increase the mechanical strength of the product. The wire drawing process is to draw metal materials to make their grains thinner, thereby improving the mechanical strength of the product. Galvanizing can form a layer of zinc on the surface of the product, and the zinc layer itself has a high hardness, which can provide additional support during the wire drawing process and prevent the metal material from tensile fracture during the wire drawing process. Therefore, galvanized products after wire drawing can increase their strength and stiffness, and improve their tensile strength and torsional resistance.

galvanized iron wire manufacturer...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read More

galvanized iron wire manufacturer

Post time: 02-06-23...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read Moregalvanized iron wire manufacturer

...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read Moregalvanized iron wire manufacturer

...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read Moregalvanized iron wire manufacturer

...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read MoreThe color of powder coating is divided into: blade blue, grass green, dark green, yellow. Spray blade gill net by hot-dip galvanized steel plate or stainless steel sheet stamping out sharp knife sheet, high tension galvanized steel wire or stainless steel wire as the core of the resistance device. Because the barbed wire shape is not easy to contact, so it can reach an excellent barrier effect. The primary raw material of the product is galvanized sheet, stainless steel plate, high quality low carbon steel wire (electric galvanized, hot galvanized, plastic coated, plastic sprayed) wire, blue, green, yellow and other colors.

galvanized iron wire manufacturer...

galvanized iron wire manufacturer 【galvanized iron wire manufacturer】

Read More

Popular articles

After the column is installed and secured, the net can be connected directly to the Internet. The tools required for this step must be special spanner, casing and matching screws. Stand the net in the middle of the two columns, and then force upward to align the net with the connecting accessories of the column.

With the improvement of people’s living standards, now many families are raising some small pets, these small pets need a stable nest, pet cage has become a more important choice of people, each pet habits and living habits will choose to adapt to the cage.

(1) In the painting construction should pay attention to ventilation, moisture-proof, fire prevention. The working environment and painting tools should be kept clean, the pressure of the air pump should be controlled within 0.63MPa, and the safety valve should be checked for failure.

After annealing, iron wire will become soft, flexibility will increase, iron is a more active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron in the dry air is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements, its production cost is lower, use and scale is wider, better protection function, so it is an important material for iron and steel parts in a strict working environment.

Latest articles

-

The drawing process of waste product drawing process has a great influence on product function. Generally, large total surface reduction rate (see area reduction rate) and small pass surface reduction rate (about ≤23%) are selected to ensure the tolerance of products. About high strength spring steel wire, the exit temperature of each pass steel wire should be controlled when drawing below 150℃, to prevent the steel wire from changing cracks due to strain aging, which is the main disadvantage of steel wire obsoletion.

-

-

Field fence line net is a streamlined, streamlined, beautiful, tacky, fashionable European elegance; The diversity of color selection, a variety of standard color card color choice, can meet different varieties, different needs. The field fence line network can be separated with a variety of methods, and according to the customer’s request.

-

-

Regarding the placement of the cage, the top of the cage should not be higher than your standing eye level. This is because tall parrots are usually superior and not easy to tame. But for overly frightened parrots it can be slightly above your eye level. The bottom of the cage is usually equipped with a tray to prevent objects such as bird seed from falling to the ground and to prevent parrots from bumping their feet through the bars at night. The chassis should be covered with newspaper and replaced daily. To help the parrot feel safer, the cage should have a solid side and not be surrounded by bars. If a solid side is hard to find, put one side of the cage against a solid wall.

-

Links

- Lithopone is a white pigment that is widely used in various industries such as paint, ink, plastics, and paper. It is a mixture of barium sulfate and zinc sulfide, and is known for its excellent covering power and brightness.

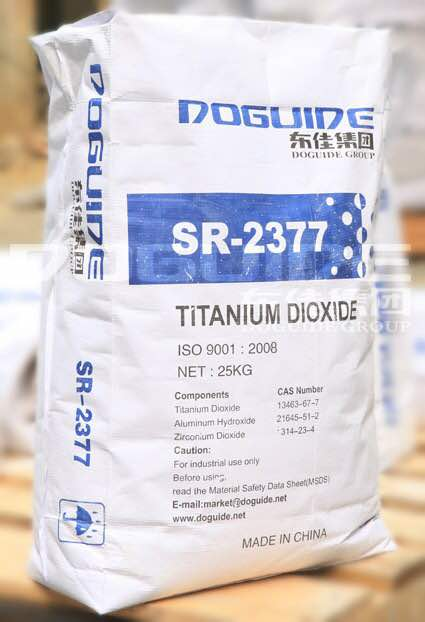

Buff percentage refers to the amount of uncoated or partially coated titanium dioxide particles in a product. A higher buff percentage generally indicates a lower level of coating, which can impact the overall performance of the titanium dioxide. Manufacturers must carefully control this percentage to ensure that their product meets the specific requirements of their customers.

- Milk powders and other dairy products

- China's OEM Titanium White Market A Comprehensive Analysis

- Furthermore, TiO2 is also an effective heat stabilizer. It helps to prevent rubber from scorching and discoloring during the manufacturing process, ensuring consistent quality and performance throughout the product's lifecycle.

In response to the allegations, Justin Comes, vice president of research and development at Mars Wrigley North America, told Health that safety is of paramount importance to Mars Wrigley. While we do not comment on pending litigation, all Mars Wrigley ingredients are safe and manufactured in compliance with strict quality and safety requirements established by food safety regulators, including the FDA.

titanium dioxide for interior and exterior wall paint material factory. It does not release harmful substances into the air, ensuring indoor environments remain safe and healthy. Furthermore, its excellent hiding power allows for effective coverage even in small spaces where natural light may be limited, creating a consistent and aesthetically pleasing finish.

titanium dioxide for interior and exterior wall paint material factory. It does not release harmful substances into the air, ensuring indoor environments remain safe and healthy. Furthermore, its excellent hiding power allows for effective coverage even in small spaces where natural light may be limited, creating a consistent and aesthetically pleasing finish.Furthermore, lithopone is a versatile pigment that can be easily mixed with other coloring agents to create custom shades and finishes. This flexibility allows leather suppliers to meet the diverse needs of their customers and produce a wide range of leather products in different colors and styles. Whether it's a classic black leather jacket or a trendy pastel-colored purse, lithopone can be tailored to suit any design requirements.

Does It Cause Cancer?

Various titanium-rich minerals, including ilmenite and rutile, can serve as starting materials for the production of highly purified Titanium Dioxide. The predominant method employed in Titanium Dioxide production is the chloride process. In this process, the mineral, along with coke and chlorine, undergoes a reaction within a fluidized bed, resulting in the formation of primarily titanium tetrachloride and carbon dioxide. Subsequently, the titanium tetrachloride undergoes purification and conversion to Titanium Dioxide. Another method involves treating ilmenite with sulfuric acid to manufacture the chemical.

There are two primary forms of titanium dioxide commercially available: anatase and rutile. The rutile form is typically used in sunscreens due to its superior ability to handle UV rays and stability in the presence of UV light. The anatase form is typically used in other types of products, such as paint. Another plus of the rutile form is that its UVA protection extends past 400 nanometers, which is the upper limit of UVA.

Colour

Lithopone B301, Lithopone B311 powder is also called C.I. 77115; Pigment White 5; Barium zinc sulfate sulfide and belongs to Product Categories of Inorganic & organic chemicals; uvcbs-inorganic. Lithopone B301, Lithopone B311 powder is used in water-based paints because of its excellent alkali resistance. It is widely utilized as a whitener and reinforcing agent for rubber and as a filler and whitener for paper. Lithopone B301, Lithopone B311 powder is considered to be poisonous because it is able to liberate hydrogen sulfide upon decomposition by heat, moisture, and acids. When heated to decomposition Lithopone B301, Lithopone B311 powder emits highly toxic fumes of SOx, ZnO, and H2S.

So, what does it all mean for you, the consumer? Should you stop eating Skittles or begin checking foods for the presence of titanium dioxide? Here's a closer look.

Price and Availability

Price and AvailabilityLithopone

Freshwater algae show low-to-moderate susceptibility to TiO2 exposure, with more pronounced toxic effects in the presence of UV irradiation. It has also been shown that nano-sized TiO2 is significantly more toxic to algae Pseudokirchneriella sub-capitata than submicron-sized TiO2. Hund-Rinke and Simon reported that UV irradiated 25 nm TiO2 NPs are more toxic to green freshwater algae Desmodesmus subspicatus than UV irradiated 50 nm particles, which is in agreement with Hartmann et al. UV irradiated TiO2 NPs also inactivated other algae species such as Anabaena, Microcystis, Melsoira and Chroococcus. It was demonstrated that smaller particles have a greater potential to penetrate the cell interior than submicron-sized particles and larger aggregates. Studies have shown that the amount of TiO2 adsorbed on algal cells can be up to 2.3 times their own weight.

zinc oxide content, %