welded wire fence panels

Latest articles

welded wire fence panels

...

welded wire fence panels 【welded wire fence panels】

Read More

welded wire fence panelsThe shape of the cage has round, square, octagonal, hexagonal and other shapes. Because the circular space uses a large area, it is more suitable for the activities of birds, and it is not easy to get hurt, so it is popular with everyone. A cage is dear to a man who loves birds, for it is inhabited by his master’s birds. If well maintained, it can be maintained for many years. Let’s look at how to maintain the cage.

...

welded wire fence panels 【welded wire fence panels】

Read More

welded wire fence panelsOrdinary blades installed on the walls of the barbed wire fence height in two metres of general construction cost in more than a dozen yuan a metre, but if the prison on the height of the wall construction modest have already reached the four or five meters so that every one meter of the cost of construction in 30-40 yuan, mainly because the work high above the risk is bigger. The construction cost is different, but the price of the blade barbed rope is the same. The construction cost is often higher than the product. In this way, the blade barbed rope factory recommends customers to use the blade barbed rope with better quality to avoid the tedious time and cost of subsequent removal and installation.

...

welded wire fence panels 【welded wire fence panels】

Read MoreWhen the barbed rope is installed in different places, the choice of barbed rope column is different. Usually, the barbed rope column we install is cement column, but the use of cement column also has its drawbacks. For example, it’s not so convenient if we install it on a steep hill where transportation is not very convenient. This time can use barbed rope with the composite column to install.

welded wire fence panels...

welded wire fence panels 【welded wire fence panels】

Read MoreCharacteristics: strong anti-corrosion performance, bright appearance, beautiful appearance.

welded wire fence panels...

welded wire fence panels 【welded wire fence panels】

Read Morewelded wire fence panels

...

welded wire fence panels 【welded wire fence panels】

Read MoreAt present, some manufacturers also use the process of sandblasting equipment for wire pretreatment, sandblasting process is carried out in the sandblasting room, but in the process of sandblasting, dust will permeate the whole sandblasting room, produce a lot of dust that is not easy to collect, and if the dust will be discharged at will.

welded wire fence panels...

welded wire fence panels 【welded wire fence panels】

Read Morewelded wire fence panels

...

welded wire fence panels 【welded wire fence panels】

Read Morewelded wire fence panels

...

welded wire fence panels 【welded wire fence panels】

Read Morewelded wire fence panels

...

welded wire fence panels 【welded wire fence panels】

Read More

Popular articles

The cage should be strong so that the bars cannot be bent or damaged by the parrot, and weak bars can be bent or damaged by the parrot and injure the parrot. Cages made of plastic coated railings can cause parrots to eat the coating and are not suitable. Quality cages are made of stainless steel, especially those made of colorful mild steel railings. Railing spacing is very important for the parrot’s safety, and the railing should always be small enough to prevent the parrot from poking its head out between the railing gaps. For small parrot species, column spacing of 1/2 inch (1.3 cm) is necessary. Medium parrot species such as grey parrots and Amazons require a 1 inch (2.5 cm) pitch, while great macaws can reach a pitch of more than 1 by inch (3.8 cm).

The impregnated hexagonal wire mesh will lose its original characteristics after corrosion, and will change in shape, color and mechanical properties, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment than dry environment easy corrosion, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated hexagonal wire mesh, prolong the service life of products.

- Three, the use of different technologies

Latest articles

-

2. Stainless steel 316 material should be used in coastal areas, which can resist corrosion of sea water.

-

-

-

Wet air in rain and snow climate, steel mesh sheet exposed, easy to rust, to avoid affecting the use of steel mesh, it is necessary to carry out simple rust prevention treatment, of course, slight rust float will not affect the use of steel mesh. Common network site storage, rainy days, heavy snow, rainy days and rainy days, how to better save the steel mesh, this is a lot of friends need to consider.

-

The chromium-plated layer has good thermal property. When the temperature is heated below 500℃, its luster and hardness are not changed obviously. When the temperature is higher than 500℃, the initial oxidation and discoloration occur, and the hardness decreases when the temperature is higher than 700℃. The friction coefficient of chrome coating is small, especially the dry friction coefficient, which is low among all metals. So the chrome coating has good wear.

-

Links

- One notable advantage is their versatility in the kitchen. With a range of sizes and shapes included in most sets, from fry pans to Dutch ovens, you can easily prepare soups, stews, casseroles, and more. They're also suitable for baking, offering a homogenous heat distribution that's perfect for bread and desserts.

Carbon steel pans are just as suitable for high heat cooking as cast iron, but with a lighter, less bulky profile. Here are some distinct advantages of using this pan.

- Moreover, cast iron griddles are not only limited to the stovetop or oven; they can be placed directly over an open flame or even taken outside for a cookout. Their versatility extends beyond the kitchen, making them perfect for camping trips, where they can be placed over a firepit, adding a smoky flavor to your al fresco dining experience.

- The Timeless Charm of Enamel-Cast Iron Skillets A Culinary Game-Changer

Delicate dishes, reducing oil needed for cooking - The Charm of Small Enamel Cast Iron Pots

- When properly cared for, enamelware cookware can last for many years, making it a worthwhile investment for any home cook. To ensure the longevity of your enamelware cookware, it is important to avoid using metal utensils that can scratch the enamel surface. Instead, opt for silicone, wood, or plastic utensils to preserve the integrity of your cookware.

Buy Cast Iron Cookware

No, a frying pan and a skillet are not exactly the same. Both are made of stainless steel, but their main difference lies in the height of the sides. Fry pans have lower sloping sides for easier flipping, while French skillets hold higher straight sides for more food or liquid.

- Another benefit worth mentioning is the aesthetic appeal of non-stick enamel cookware. Available in a wide range of colors and designs, they add a pop of color to any kitchen, transforming cooking into a more visually pleasing experience.

- Beyond its practical uses, the Iron Meat Press can also be employed in creative ways. Chefs have used it to flatten chicken breasts, compress sandwiches for enhanced flavor infusion, or even to press herbs and spices for homemade rubs. Its versatility is a testament to the ingenuity of those who have relied on it throughout history.

No, aluminum pans should be hand-washed only. Aluminum cannot withstand the high heat of the dishwasher or harsh dishwashing chemicals, which can tarnish or stain the surface.

This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning

This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning cast iron flat top gas grill.

cast iron flat top gas grill. polished cast iron skillet for sale. Its timeless design adds a rustic touch to your kitchen, and with proper care, it can be passed down through generations, accruing a patina that enhances its non-stick properties over time.

polished cast iron skillet for sale. Its timeless design adds a rustic touch to your kitchen, and with proper care, it can be passed down through generations, accruing a patina that enhances its non-stick properties over time.

It's also a great option for those who prefer a healthier cooking method, as it allows for the easy draining of excess fats and oils It's also a great option for those who prefer a healthier cooking method, as it allows for the easy draining of excess fats and oils

It's also a great option for those who prefer a healthier cooking method, as it allows for the easy draining of excess fats and oils It's also a great option for those who prefer a healthier cooking method, as it allows for the easy draining of excess fats and oils cast iron flat top grill.

cast iron flat top grill. From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

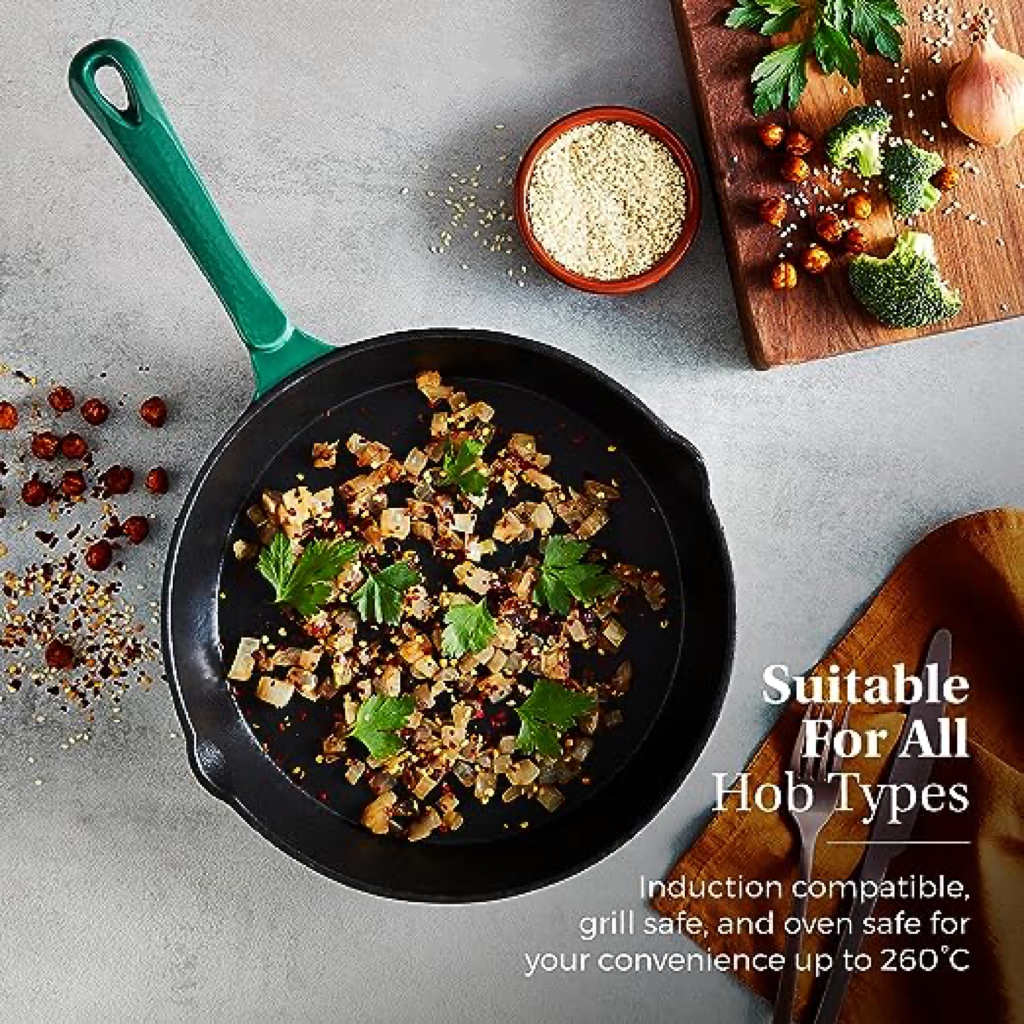

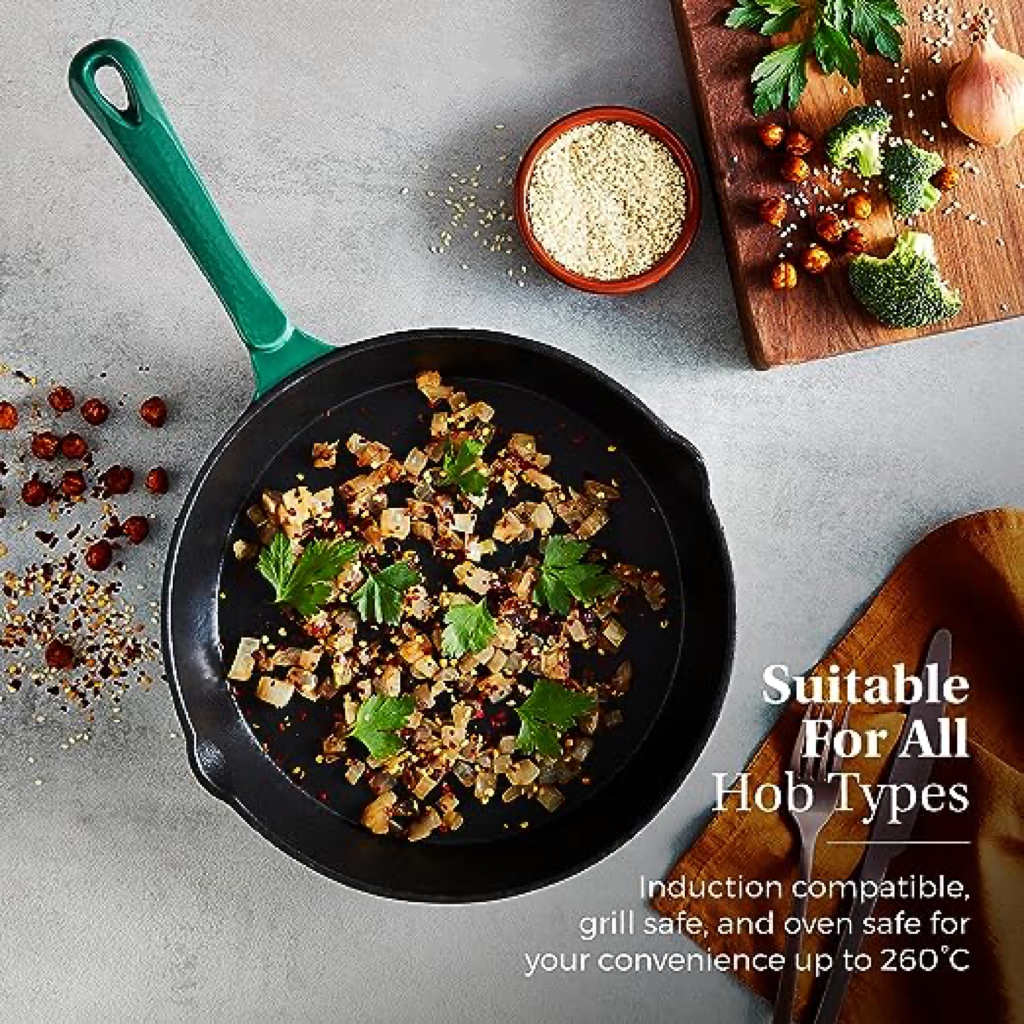

enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe. The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots

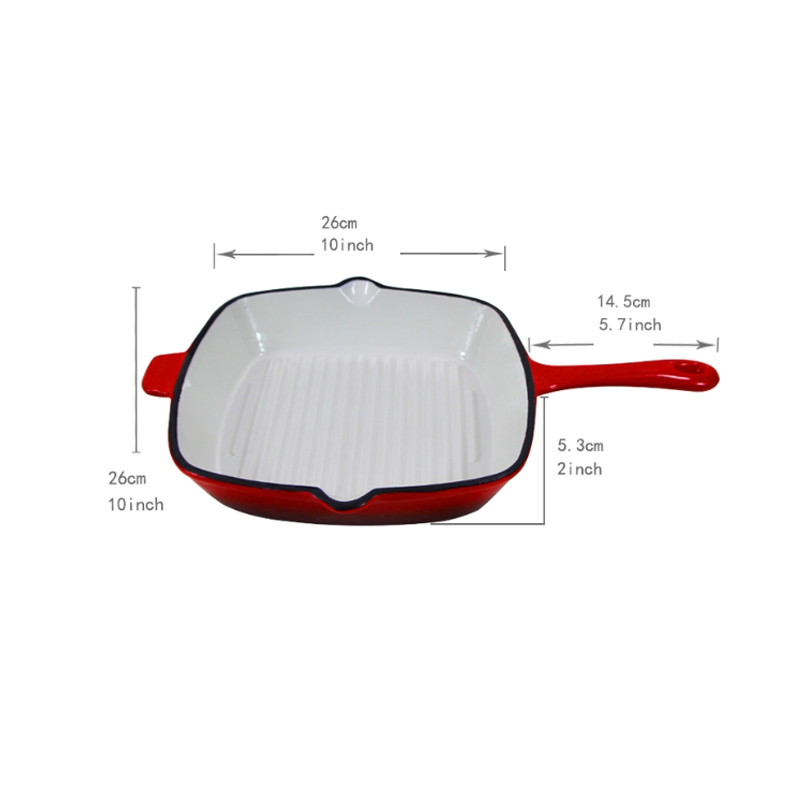

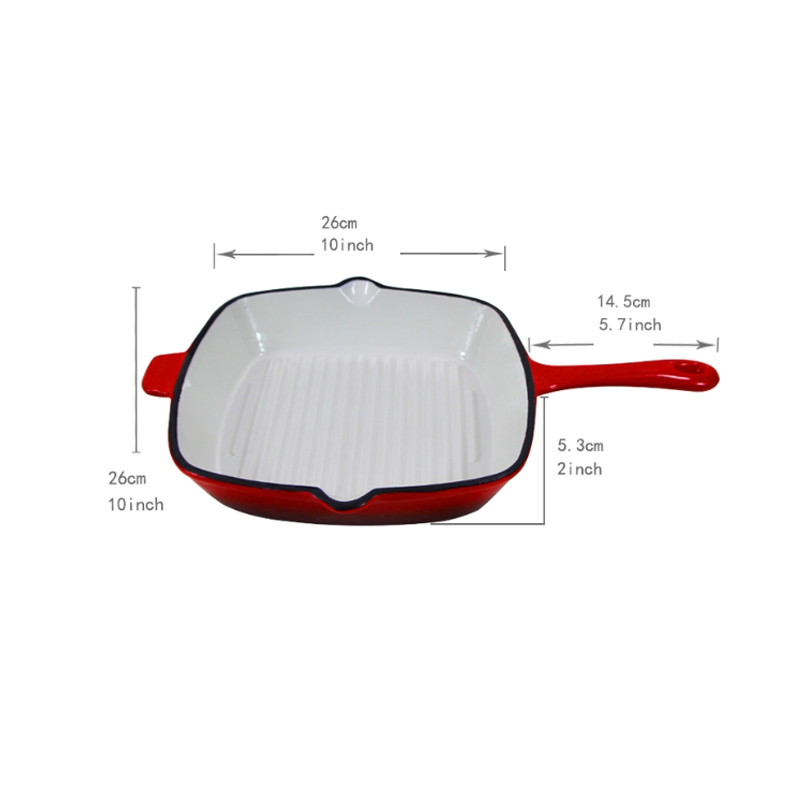

The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots enamel induction grill pan. Whether you're searing a steak or gently sautéing vegetables, the consistent heat will help you achieve perfect results every time.

enamel induction grill pan. Whether you're searing a steak or gently sautéing vegetables, the consistent heat will help you achieve perfect results every time.Cleaning Griddle On The Stove

When making your choice, consider the material of the pan, its heat distribution properties, and how easy it is to clean and maintain. Take into account any drawbacks, such as the need for special care and maintenance or the limited lifespan of the non-stick coating.