1.5 inch welded wire mesh

Latest articles

1.5 inch welded wire meshHexagonal mesh is made of galvanized iron wire woven by automatic mesh machine, mesh into regular hexagonal shape, mesh standard, beautiful, mesh size can be customized according to customer requirements, usually 27mm,20mm, 13mm, wire diameter from 0.40mm to 1.20mm, to meet the requirements of different customers.

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More1.5 inch welded wire mesh

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read MoreGalvanized wire A stable layer of zinc is coated on the outside of the wire, which is used to protect the wire and make the wire service life longer. When producing galvanized wire, the wire is pickled. Pickling is to use some acid mist or acid to wash off some oxides on the surface of iron, that is, rust, and some other corrosive substances, to achieve the purpose of cleaning iron, so that zinc will fall off when galvanizing.

1.5 inch welded wire mesh...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More

1.5 inch welded wire meshAdvantages: The cost of hot dip galvanized rust prevention is lower than that of other paint coating. In suburban environment, the standard hot-dip galvanized rust prevention thickness can adhere to more than 50 years without repair. In urban or offshore areas, the standard hot-dip galvanized rust protection layer can last 20 years without repair. Galvanized layer and steel is a metallurgical connection, into a part of the steel surface, so the durability of the coating is more reliable.

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More3. Keep the rinse water clean after pickling the steel wire

1.5 inch welded wire mesh...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More

1.5 inch welded wire meshGalvanized wire in acid, alkali, sodium chloride aqueous solution of poor corrosion resistance, in the atmosphere containing carbon dioxide and hydrogen sulfide, as well as Marine atmosphere is not corrosion resistance. In high temperature and high humidity air and containing organic acid atmosphere is small, galvanized layer is also easy to be corroded. Galvanized wire and general wire is very different, general wire is cheap, and because the iron is not very stable, easy to rust in the wet place, so the stability is not very good, the life is not very long.

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More1.5 inch welded wire mesh

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More

1.5 inch welded wire meshWe must have a certain understanding of the hexagonal network, we are the beautiful appearance of the hexagonal network, hexagonal network is not only very beautiful appearance, in fact, the practical value of survival is very high. To introduce the relevant information should be very clearly know the highway guardrail net, hexagonal wire netting in all kinds of fence netting, in the value of the high-speed on the road more MaoJian, it not only be used in all kinds of road, in a sports ball games venue and try our best to take care of landslides, also has reached very matter effectiveness.

...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More③ Galvanized iron wire shall not be damaged when it is tightened.

1.5 inch welded wire mesh...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read MoreIn the production of its own, to avoid injury, wearing the corresponding work clothes is very necessary, so that not only can avoid the occurrence of accidents, but also can better realize the production and processing of products. The application of black iron wire in the process is mainly through the hot metal billet rolled into a six-and-a-half-millimeter wire, and then put it into the drawing device to draw into different diameter of the wire, gradually reduce the aperture of the drawing disk, cooling and annealing, coating and other processes to make a variety of different specifications of the wire.

1.5 inch welded wire mesh...

1.5 inch welded wire mesh 【1.5 inch welded wire mesh】

Read More

Popular articles

This oxide film has greater elasticity and lubricity, does not affect the accuracy of parts. Therefore, the parts of precision instruments and optical instruments, spring steel, thin steel sheet, fine steel wire and so on are commonly bluing treatment. The commonly used galvanizing treatment of large roll galvanized wire is equivalent to forming a protective layer on the surface of the iron wire. The commonly used methods are hot dip galvanizing, hot spray plating, vacuum plating and so on. Different methods have corresponding characteristics.

- Stainless steel wire drawing is a metal working (stainless steel) process, is a popular surface treatment technology in the stainless steel and aluminum products industry today. It is the effect of drawing stainless steel and aluminum products. So galvanized wire and stainless steel wire are two different products. Defects such as surface film and surface inclusion can be found and treated by conventional techniques in order to locally remove the surface film and surface inclusion from the surface of galvanized iron wire. Excess foam is formed when soap and surfactants such as saponified fats are brought into the tank.

- Bird food, now raising birds can be fed with bird food on the market, which is more convenient, of course, you can also feed some cereals, herbs and so on, in order to supplement nutrition.

Latest articles

-

The common type of barbed rope is double-strand barbed rope, and the models are 2.0*2.0mm, 2.25*2.25mm, 2.7*2.25mm, and all of them are galvanized barbed rope (plastic coated barbed rope is rarely used). The barbed distance (that is, the distance between winding wires) is generally 14 cm. Here’s what these models mean:

-

③ The galvanized iron wire shall not be damaged when it is tightened.

-

The reason why there are black spots in wire mesh welding is that the action of wire feeding should be timely filled in the melting time, and the development should be appropriate. There is no argon gas, long burning, large current, long distance, blunt tungsten needle and high molten pool temperature are the fundamental reasons for blackening. Continuous burning, is about active welding machine energy selection, machine welding will appear black spots.

-

Galvanized wire can be seen as iron wrapped in carbon, when extinguished, the surface is comparable to shallow carbon can contact with oxygen, produce carbon dioxide gas, will wrap it in iron (this is a molten state) radiation in. The more carbon there is in the galvanized wire, the more likely it is to spark. The iron-encased carbon is like dynamite in a dynamite bag, blowing the iron away from time to time.

-

Stainless steel barbed wire is often used in various engineering projects because of its good anti-corrosion ability, but it is difficult for ordinary families to accept because of its relatively high price. So what material of barbed rope anticorrosion ability is better?

-

Non-proportional extension strength: It is mainly for hard steel without yield point. It is defined as the stress where the residual elongation of the standard distance part reaches 0.2% of the length of the original standard distance.

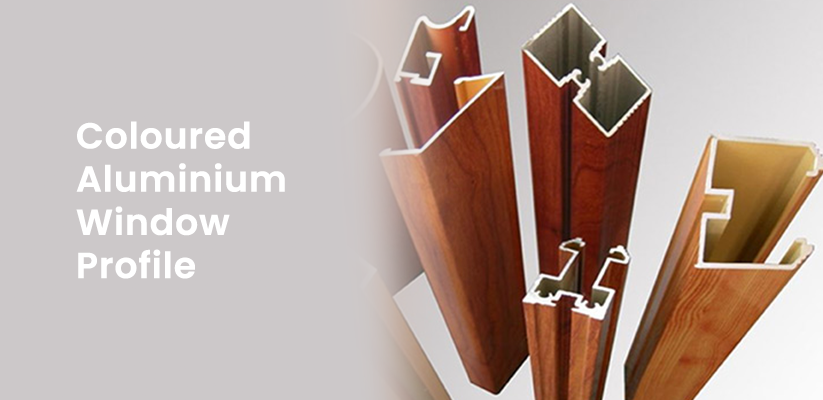

The surface of aluminum alloy is polished and polished by oxidation. The window sash frame is large and can be inlaid with a large area of glass, so that the indoor light is bright enough, and the contrast between the interior and the exterior of the facade is enhanced, and the living room is more rich. Aluminum alloy itself is easy to extrusion, the cross-section of the profile size is accurate, the machining accuracy is high, so in the decoration, many owners choose to adopt aluminum alloy doors and windows.

For polishing: pear velvet+heat shrinkable film

Wrought iron is generally longer-lasting than cast iron. As we said, cast iron is harder but it’s also more brittle. The extra carbon in its molecular structure compared with wrought iron results in internal stress points that are more likely to fracture under extreme stress rather than bend. There are advantages and disadvantages to this: cast iron is more likely to retain its exact shape without undergoing any warping or bending.

Throughout history, spears have held a significant place in various cultures, serving as both a weapon and a tool. The term real spears evokes images of finely crafted weapons that are not merely replicas but authentic artifacts that encapsulate the artistry and functionality of ancient craftsmanship. From hunting to warfare, these weapons have evolved alongside humanity, taking on symbolic meanings and becoming integral to various cultural narratives.

Today, the legacy of head spearing lives on primarily through historical accounts, anthropological studies, and preserved artifacts. Museums showcase these ancient weapons, providing a window into a past where such practices were integral to societal norms. Furthermore, the remnants of head spearing traditions have inspired contemporary art and literature, serving as a reminder of the complex tapestry of human history.

The Allure of Decorative Wrought Iron Pieces

Remove any non-metal parts, such as wooden panels or plastic decorations, that may be attached to the iron. This ensures that the metal is clean, which is crucial for recycling.

ITEM #6 – WARRANTY INFORMATION

aluminium windows profile.

Step 3 Clean the Rollers and Track

Another compelling aspect of wrought iron gate ornaments is their customizability. Homeowners can collaborate with skilled artisans to create bespoke designs that perfectly reflect their personality and home architecture. This level of personalization has led to a resurgence in the appreciation of wrought iron work, as people seek to imbue their properties with unique character and charm.

6061 Aluminum Grade

Let’s talk numbers for a moment. After all, one of the most commonly asked questions we see is in regard to the wrought iron vs aluminum fence cost.

cast iron designs. The material can be molded and shaped into a wide variety of forms, allowing for endless possibilities in design. Whether you prefer a more traditional and ornate style or a more modern and minimalist look, cast iron can be customized to suit your preferences.

The Parts of a Wrought Iron Fence

It is quite popular and can be used with self-tapping screws or merely threaded to take a machine screw.