how to use wall screws

Latest articles

how to use wall screwsThe barbed wire factory will store the inventory of the barbed wire blade in the appropriate place because of the understanding of the product characteristics.

...

how to use wall screws 【how to use wall screws】

Read More

how to use wall screwsSome customers are just for ordinary fencing, but the pictures provided to the barbed rope factory are indeed applied to the barbed rope products in prison, maybe because the customers prefer the style, but such products are really a little overqualified to be installed in ordinary areas. Even if the customers prefer such barbed rope products, the higher price is prohibitive. The price and quality of the prison rope are certainly not the level of the rope we contact in our daily life.

...

how to use wall screws 【how to use wall screws】

Read Morehow to use wall screws

...

how to use wall screws 【how to use wall screws】

Read Morehow to use wall screws

...

how to use wall screws 【how to use wall screws】

Read MoreIn addition, many luxury cat cage, dog cage, parrot cage, bird cage and flock bird cage, will use iron square tube. Luxury cage using iron square tube is generally as a cage body frame, and then on each side of the welded iron wire. Square tube cage is characterized by more beautiful shape design, cage body more solid, more surface treatment methods.

how to use wall screws...

how to use wall screws 【how to use wall screws】

Read Morehow to use wall screws

...

how to use wall screws 【how to use wall screws】

Read Morehow to use wall screws

...

how to use wall screws 【how to use wall screws】

Read MoreHard black galvanized iron wire is made of low carbon steel wire directly drawn by drawing machine. The primary characteristics of hard black galvanized iron wire are high hardness and bright appearance. Primary use for welding hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawn. The primary feature of soft black galvanized iron wire is good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving process, electric welding mesh, welding process products.

how to use wall screws...

how to use wall screws 【how to use wall screws】

Read More

how to use wall screws...

how to use wall screws 【how to use wall screws】

Read MorePerformance characteristics of zinc coating: zinc layer of thick galvanized wire zinc layer crystallinity meticulous, uniform and no gap, good corrosion resistance; The zinc layer obtained by electrogalvanizing is very pure and corrodes slowly in the gas, liquid and fog of acid and alkali, which can effectively protect the steel matrix. Galvanized layer can also be chromic acid passivation treatment into a variety of colors, beautiful and generous, with good decorative; The zinc layer on the galvanized wire has good ductility, can be cold blanking, rolling, bending and other molding without damage to the zinc layer.

how to use wall screws...

how to use wall screws 【how to use wall screws】

Read More

Popular articles

There is a connection between the hook mesh and the aperture, in short, the general hole small hook mesh, the wire is also very small; Aperture is large, hook mesh wire is generally larger. The weaving of the hook mesh also has certain rules, using the first pre-bent into a wavy wire, and then woven into the hook mesh. According to the knitting method, the hook mesh can be divided into: closed weaving, two-way plain weaving, one-way corrugated weaving, two-way plane weaving, two-way corrugated weaving, rectangular hole weaving.

Latest articles

-

Large rolls of galvanized silk play a very important role in our life. Made of low carbon steel rod processing, after drawing forming, pickling rust removal, high temperature annealing, hot dip galvanized. Cooling and other process processes. Galvanized wire is divided into hot galvanized wire and cold galvanized wire (electric galvanized wire). Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance.

-

After annealing, iron wire will become soft, flexibility will increase, iron is a more active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron in the dry air is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements, its production cost is lower, use and scale is wider, better protection function, so it is an important material for iron and steel parts in a strict working environment.

-

3, reduce the bivalent iron ion in the plating aid used for hot plating wire, reduce the formation of zinc slag

-

-

-

Links

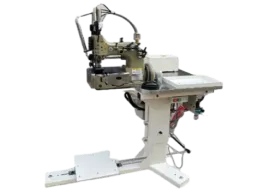

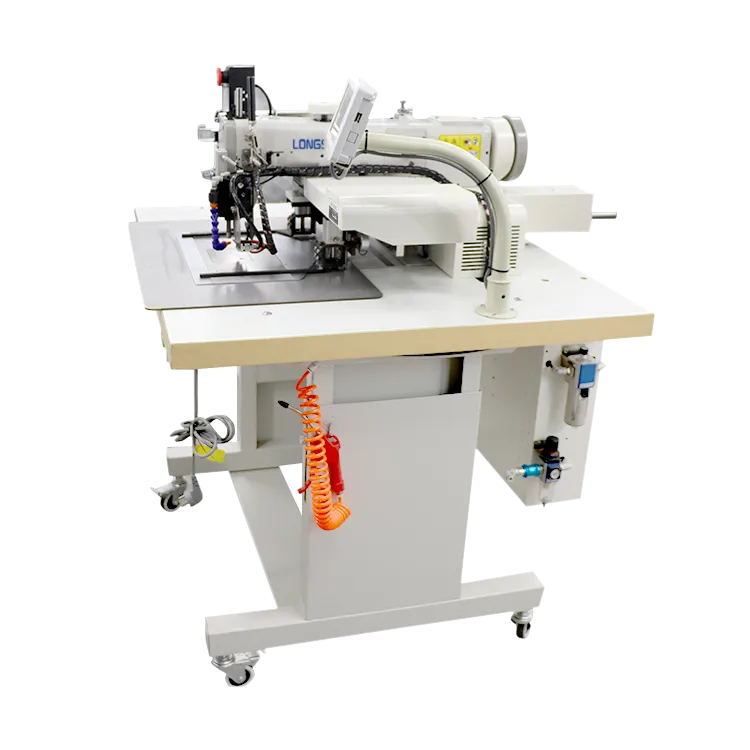

- Domestic special sewing machines are essential tools for individuals who are passionate about sewing and crafting. These machines offer a range of features and capabilities that make them ideal for a variety of projects, from simple repairs to intricate embroidery. Whether you are a beginner or an experienced sewer, a domestic special sewing machine can help you bring your creative vision to life.

Another noteworthy feature of the overlock chain stitch is its speed and efficiency. Overlock machines are designed to sew and finish seams simultaneously, which significantly reduces the overall sewing time. This efficiency is particularly beneficial in mass production settings, where time and precision are paramount.

Sew Leather with a Regular Sewing Machine Tips and Techniques

The Importance of Industrial Leather Sewing Machines

An overlocker, also known as a serger, is an indispensable tool for both professional and amateur seamsters. Unlike a standard sewing machine, which primarily stitches fabric together, an overlocker is designed to finish edges and seams, giving garments a polished look while preventing fraying. With its ability to trim excess fabric as it works, an overlocker streamlines the sewing process and introduces creative possibilities. So, what can you do with an overlocker? Let’s explore various techniques and projects that highlight this versatile machine’s capabilities.

Technological Advancements

While there are many benefits to using a hand crank sewing machine, there are some challenges to consider. The learning curve can be steep for those who are accustomed to electric machines that do much of the work automatically. Additionally, sewing large pieces of leather may require physical effort, which can be tiring over extended periods.

Furthermore, many Dressmaker models come equipped with multiple stitch patterns, including decorative stitches that allow for creative expression. Whether it’s a floral pattern for a quilt or a simple zigzag for reinforcing seams, this machine's variety makes it a staple in any sewing room.

Manual bobbin winding can often lead to mistakes, such as incorrect tension settings or uneven winding, which can create frustration and lead to wasted materials. With an automatic bobbin winder, these issues are significantly diminished. The machine handles the winding process efficiently, allowing the sewist to focus on their creativity rather than managing technical errors. This not only saves time but also reduces thread waste and the frustration associated with constant adjustments.

A chain stitch sewing machine is a valuable asset for anyone engaged in sewing, from hobbyists to professional garment manufacturers. Its speed, flexibility, and cost-effectiveness make it an appealing choice for various sewing applications. With several purchasing options available, you are bound to find the perfect chain stitch machine to meet your needs. Whether you're enhancing your sewing hobby or boosting your production capabilities, investing in this versatile equipment is sure to elevate your sewing experience.

auto oil sewing machine. Proper lubrication ensures that the needle and bobbin move smoothly, resulting in consistent and accurate stitches. This is particularly advantageous for complex patterns and heavy-duty projects where precision is paramount.

auto oil sewing machine. Proper lubrication ensures that the needle and bobbin move smoothly, resulting in consistent and accurate stitches. This is particularly advantageous for complex patterns and heavy-duty projects where precision is paramount.4. User-Friendly Operation With many modern models designed with intuitive interfaces and robust software, operating a two needle embroidery machine has become accessible even for beginners. Comprehensive tutorials and guides often accompany these machines, providing users with the resources needed to get started.

Just like any other piece of equipment, a sailmaker sewing machine requires regular maintenance to ensure optimal performance. Sailmakers are advised to clean their machines after each use, lubricating moving parts and checking for any wear on the needles or other components. Regular maintenance prolongs the life of the sewing machine and maintains its ability to produce high-quality stitches.

Factors Influencing Price

As we move further into a world dominated by fast fashion and rapidly changing trends, the double needle sewing machine remains a reliable companion for both professional tailors and sewing enthusiasts alike. Its combination of versatility, efficiency, and quality makes it an indispensable tool in modern garment construction. Whether it’s creating a simple hem or crafting a high-fashion piece, the double needle sewing machine ensures that every stitch counts, reaffirming its place in the heart of the textile industry. Investing in this machine not only benefits the quality of the work but also empowers creators to explore their artistic potential in the ever-evolving landscape of fashion design.

In conclusion, the floating foot sewing machine has redefined the sewing landscape by providing enhanced precision, flexibility, and user-friendly features. Whether you are a budding enthusiast or a seasoned professional, integrating this innovative sewing tool into your crafting toolkit can significantly elevate your sewing experience. As technology continues to evolve, it’s exciting to foresee what other advancements will shape the future of sewing, but for now, the floating foot machine stands out as a definitive asset in the world of textiles. Embracing this technology not only streamlines the sewing process but also opens up endless possibilities for creativity and craftsmanship in every stitch.

Industrial Sewing Machines: These tools are made for use in businesses. They are made to run for a long time, often several hours a day, and move a lot of stuff. They are usually found where many things are made, like clothing plants, upholstery shops, and other large-scale production settings.

The Advantages of Automatic Needle Threader Sewing Machines

While heavy-duty sewing machines offer numerous benefits, it is essential to assess your specific needs before investing in one. Consider the types of projects you plan to work on, the materials you will be using, and your sewing experience level. If you primarily focus on lightweight fabrics and basic garments, a standard sewing machine may suffice. However, if your projects often include thicker materials or require more advanced capabilities, a heavy-duty sewing machine would be a beneficial addition to your sewing arsenal.

Heavy duty sewing machines are designed to handle thick fabrics and multiple layers, making them indispensable in industries that require robust stitching capabilities, such as upholstery, leatherworking, and manufacturing of workwear. These machines are built with superior materials and components, ensuring they can withstand the rigors of daily use. However, what truly sets them apart is the motor powering them.

how to use the double needle in sewing machine. Make sure to thread each needle correctly to avoid tangles and breakages.

For those who want a more industrial-grade machine, the JUKI TL-2010Q offers unmatched performance for heavy fabric sewing. With its high-speed stitching capabilities and precision, it’s perfect for serious tent makers looking for professional quality.

In the world of garment manufacturing, efficiency and precision are paramount. One of the essential tools that help achieve these goals is the industrial overlocker, commonly known as an overedge or serger machine. If you’re in the market for an industrial overlocker for sale, this guide will provide you with valuable insights into what to consider, the benefits of using an overlocker, and tips on making the right investment.

2. Walking Foot Mechanism A walking foot, or even a roller foot, is essential for sewing leather, as it helps to grip the material evenly, preventing slipping during operation. This feature is particularly important when sewing multiple layers of leather.

Optimizing Overlock Machine Costs

Features of the Single Needle Edge Cutter Machine

Moreover, the speed shuttle hook offers a unique opportunity for individual athletes to train independently, which can be especially advantageous for those with busy schedules. Traditional team training sessions require coordination with multiple individuals, often leading to logistical challenges. By utilizing the speed shuttle hook, athletes can maximize their training time and develop their skills at their own pace, ensuring they can hone their abilities regardless of external circumstances.

1. Custom Stitch Programming One of the most appealing features of programmable pattern sewing machines is the ability to create custom stitches. Users can design unique patterns and save them in the machine's memory for future use. This flexibility not only enhances creativity but also saves time, as users don’t have to replicate intricate designs manually each time.

4. Reduction in Labor Costs While the initial investment in CNC sewing machines can be high, they can ultimately lead to reduced labor costs. With machines performing the majority of sewing tasks, businesses can save on labor expenses and allocate human resources to more complex or creative tasks that machines cannot handle.

2. Control A handheld stitcher provides greater control during the stitching process. Crafters can easily maneuver the tool to create tight, even stitches, which can be challenging with a needle and thread alone. This control is essential for ensuring the longevity and durability of leather items, as well-crafted seams can prevent future wear and tear.

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile manufacturing. Its efficiency, consistency, and technological advancements not only boost productivity but also help address sustainability concerns. As the fashion and textile industries continue to evolve, the hi-speed lockstitch machine will undoubtedly play a critical role in shaping the future of garment production, offering opportunities for both innovation and improved operational effectiveness. Embracing this technology is essential for manufacturers aiming to thrive in an increasingly competitive marketplace.

What Can I Do with an Overlocker?

4. Bernina 770 QE For those who are ready to invest in a high-end model, the Bernina 770 QE is a luxurious option that offers a wide array of features, including a dual feed system and a large sewing area. It’s an excellent choice for serious leather crafters looking for professional quality.

At the core of the double needle sewing machine's functionality is its unique design. It features two needles that are threaded separately but operate simultaneously, allowing for stitches that are both strong and visually appealing. The machine typically comes equipped with a dedicated thread tension mechanism for each needle, ensuring that the fabric is properly secured without any puckering or uneven stitches.

- Foot and Needle Options Ensure the machine accommodates various foot types and needle sizes, as this flexibility can greatly enhance your sewing experience.

At the heart of long arm sewing is the long arm quilting machine, which typically features a large table or frame and a specialized sewing mechanism. Unlike standard sewing machines, long arm machines allow for the movement of the fabric while the sewing head remains stationary, or vice versa, depending on the design. This setup gives users the ability to quilt large quilts without the struggle of maneuvering tons of fabric through the small throat space of a regular machine.