aluminum perforated metal

Latest articles

aluminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read Morealuminum perforated metal

...

aluminum perforated metal 【aluminum perforated metal】

Read More

aluminum perforated metalWith the rapid development of market economy, all walks of life are improving the production process and quality of products, galvanized iron wire industry can not be an exception, of course. However, as a result of galvanized iron wire types differ, its characteristics and production process is also different. Galvanized wire selection of high quality low carbon steel rod processing, is the selection of high quality low carbon steel.

...

aluminum perforated metal 【aluminum perforated metal】

Read More

Popular articles

(1) Easy to use, only the mesh surface tile wall, building cement can be used;

- Non-proportional extension strength: It is mainly for hard steel without yield point. It is defined as the stress where the residual elongation of the standard distance part reaches 0.2% of the length of the original standard distance.

Steel wire mesh by its own unique advantages in construction occupation, reinforcement anti-crack occupation is indispensable reinforcement anti-crack data, high product error is small, mesh mesh uniform, welding firm, strong acceptance, not easy to deformation, steel wire mesh in different fields have different called, in bridge engineering construction people call it soft reinforcement.

Latest articles

-

In order to pack and bundle galvanized wire on the surface of the deposit layer to remove the surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless. Small homogeneous particles of large denier present in the tank can stabilize the foam layer. To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the intake of surfactant. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

-

The advantages of the blade stabbing rope (1) lightweight, high strength, never rust, good softness, fatigue resistance, impact resistance, breaking force, the overall structure is strong and durable, the service life is more than 30 years; (2) Close to nature, green environmental protection, highly effective protection of bird feathers and animal skin, effectively prevent rodents and other animals from biting, to give animals a safe and comfortable living environment; (3) Good visibility through l, luxurious appearance, novel style, itself is a big landscape. We can send you samples and make sure they are consistent. Our TECHNICIANS and ENGINEERS can also visit our factory free of charge for site investigation and design. According to your requirements and specific application environment, we can provide detailed material, rope diameter, hole distance and overall structure advice to guide installation.

-

The small homogeneous particles with large denier in the tank can stabilize the foam layer, but the accumulation of too many solid particles will cause explosion. Coating with activated carbon to remove surfactant, or filtering to make the foam less stable, are effective measures. Other measures should also be taken to reduce the amount of surfactant brought in to Z. The speed of electroplating can be significantly reduced by the addition of organic matter. Although the chemical formulation is conducive to high deposition rate, but the organic matter with the coating thickness can not meet the requirements, so activated carbon can be used to treat the tank liquid.

-

-

4: spray blade barbed rope long service life.

-

A. When the thickness of the plating is 3-4 mm, the zinc adhesion should be less than 460g/m, that is, the average thickness of the zinc layer is not less than 65 microns.

Links

- Fireproof adhesive tape is designed to withstand extreme temperatures, typically ranging from -50°C to 1000°C, depending on the specific type. Its primary function is to prevent the spread of fire by creating a heat-resistant barrier. It can be applied to cable wraps, electrical conduits, HVAC systems, and even structural joints, ensuring that fire does not penetrate through these potential entry points.

Learn More or Buy Now.

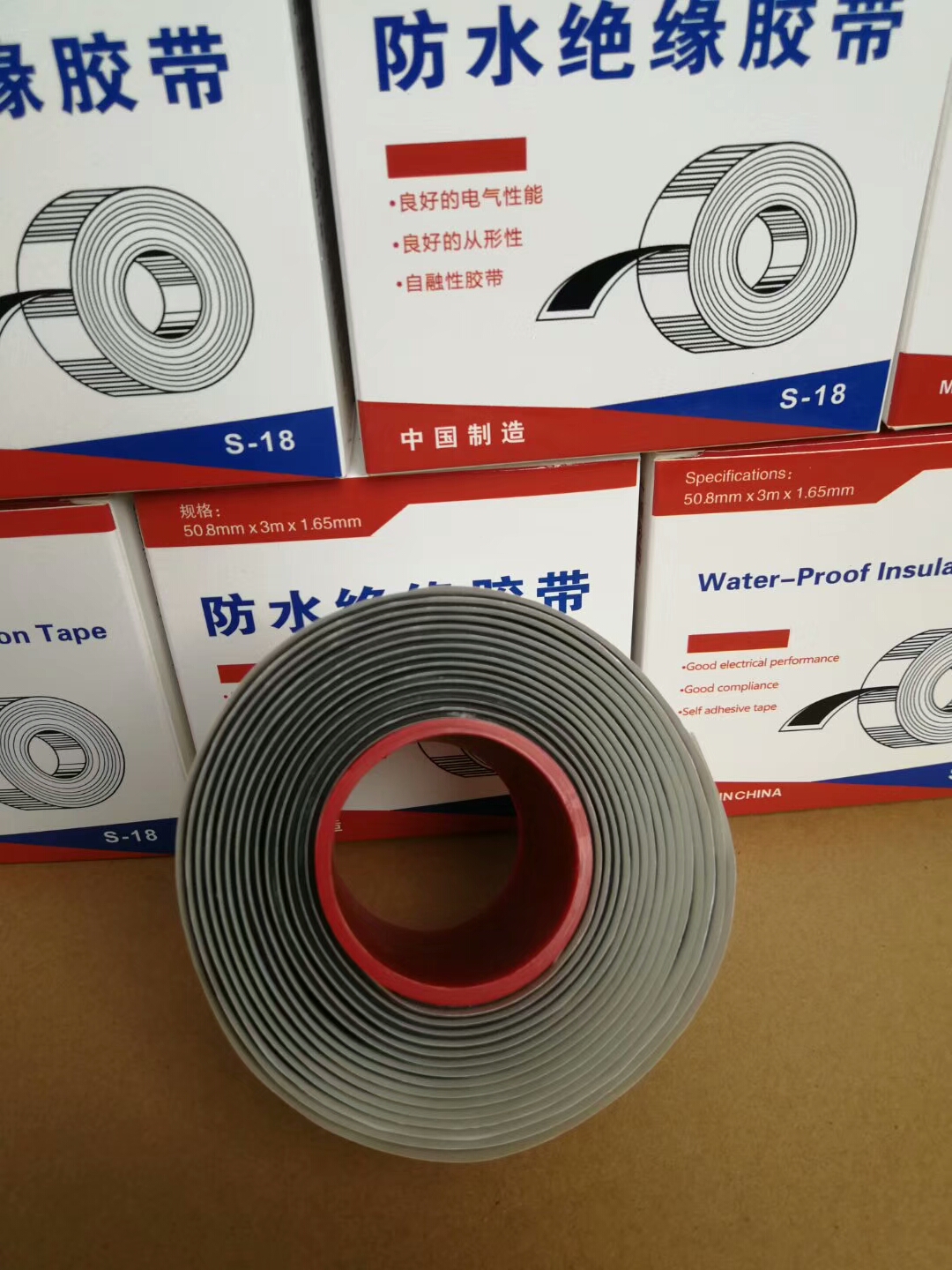

A versatile tape that can be used for everything from sealing pipes and hoses to general waterproofing and electrical cable splicing.

In the realm of construction and home improvement, the materials used play a crucial role in ensuring safety and durability. Among these materials, drywall has long been a favored choice for interior walls and ceilings due to its ease of installation and finishing. However, as fire safety becomes a growing concern, especially in residential and commercial buildings, the importance of fire-resistant drywall tape cannot be understated.

Applications Across Industries

2. Durability and Longevity Butyl rubber sheets exhibit remarkable resistance to various weather conditions, including extreme temperatures, UV light, and ozone exposure. This durability means that roofs made from butyl rubber can last significantly longer than traditional roofing materials, reducing the need for frequent replacements and repairs.

butyl rubber roofing sheet

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.Unlike traditional tapes, silicone self-adhesive tape does not leave behind a sticky residue. This means it won't attract dust or dirt, making it ideal for long-term use.

Red and white floor marking tape is typically used in settings where clear visual communication is essential. The highly contrasting colors draw attention and provide clear cues. Common applications include

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

fire resistant adhesive tape. In manufacturing plants, they are used to mark escape routes and fire-sensitive areas, contributing to a safer working environment.

fire resistant adhesive tape. In manufacturing plants, they are used to mark escape routes and fire-sensitive areas, contributing to a safer working environment.

hazard floor tape. Choose the appropriate type of tape based on the specific hazard being marked and the environment in which it will be used.

hazard floor tape. Choose the appropriate type of tape based on the specific hazard being marked and the environment in which it will be used. rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.https://www.fastenersystems.com/products/assorted-tape

Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations

Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations clear waterproof flex tape. This means that once you've applied the tape, you can trust that it will remain in place until you're ready to remove it.

clear waterproof flex tape. This means that once you've applied the tape, you can trust that it will remain in place until you're ready to remove it.Flex Tape Black is easy to use, with a simple peel-and-stick application process. This makes it accessible for users of all skill levels, from experienced handymen to DIY novices. Plus, the tape can be cut to size, allowing you to customize it to fit your specific repair needs.

flex tape black 4 in x 5 ft