rust resistant drywall screws

Latest articles

rust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read More

rust resistant drywall screwsHot dip galvanizing is then oiled and chromed. The quality of hot-galvanized sheet produced by this method is significantly improved compared with that by wet galvanizing method. It is only valuable for small-scale production. Continuous galvanizing production line includes a series of pretreatment procedures, such as alkali degreasing, hydrochloric acid pickling, water washing, solvent coating, drying, etc., and the original plate needs to be annealed in cover furnace before entering the galvanizing line.

...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read More

rust resistant drywall screws

Post time: 14-06-22...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read Morerust resistant drywall screws

...

rust resistant drywall screws 【rust resistant drywall screws】

Read MoreOf course, the quality of any product is also affected by the implementation of the manufacturer’s norms. If it is the manufacturer of electric welding mesh in production, it does not have a high implementation of the norms, or the procedural norms on the production line have decreased, or there is no higher requirements on the production link.

rust resistant drywall screws...

rust resistant drywall screws 【rust resistant drywall screws】

Read More

Popular articles

Stainless steel wire rope is widely used in engineering cranes. It is generally made of many high strength steel wires. It first consists of a single wire wound together to form a strand, and then some of the strands are wound into a rope core, and then the outer strands composed of other strands are wound around the rope core to form a wire rope.

Latest articles

-

-

-

Hexagonal mesh is made of galvanized iron wire woven by automatic mesh machine, mesh into regular hexagonal shape, mesh standard, beautiful, mesh size can be customized according to customer requirements, usually 27mm,20mm, 13mm, wire diameter from 0.40mm to 1.20mm, to meet the requirements of different customers.

-

-

Twist flower hexagonal network customized quotation needs to provide the following parameters:

-

Links

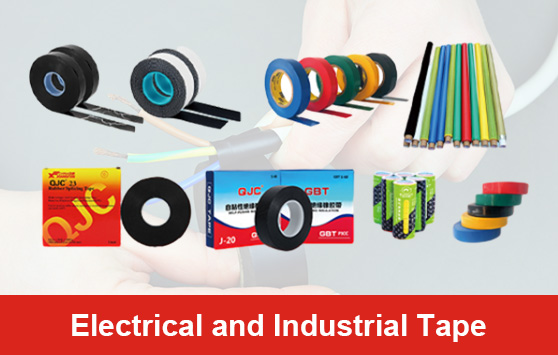

PlB self-amalgamating Tape

Elongation: 685%

. It eliminates the need for special tools or equipment, making it an ideal choice for quick fixes around the house. From patching up garden hoses to creating temporary weather seals, the tape provides a user-friendly solution that doesn't compromise on strength or longevity.

. It eliminates the need for special tools or equipment, making it an ideal choice for quick fixes around the house. From patching up garden hoses to creating temporary weather seals, the tape provides a user-friendly solution that doesn't compromise on strength or longevity.There are several different types of materials that can be used to make a wiring loom wrap, including plastic, fabric, and tape

. Each material has its own set of advantages and disadvantages, depending on the specific requirements of the vehicle and its environment.automotive wiring loom wrap

Well Pump Electrical Control Boxes

Electrical tape, also known as insulating tape, is widely used to insulate electrical wires and connections. It serves multiple purposes, including protecting wires from moisture, abrasion, and extreme temperatures. However, when it comes to fire safety, not all electrical tapes are created equal. Fire-resistant electrical tape is specially designed to withstand high temperatures and inhibit the spread of flames, making it an essential tool in fire prevention.

A nice, sturdy well pump control box will let you enjoy the comfort of having water, and avoid a lot of problems and fees that come with bad ones.

- Power Plants In electricity generation facilities, insulation tape is critical for securing connections and protecting sensitive components from high voltage electricity.

what is rubber splicing tape used for. The tape can be used to repair damaged hoses, gaskets, and seals, as well as to provide insulation and protection for electrical components. This helps to extend the lifespan of the equipment and ensure its safe and reliable operation.

“There are many kits and products available to electricians today that simplify their work and help increase productivity,” Anderson says. “The properties of electrical tapes have also been steadily improved over the years. These proven products can be adapted to many important electrical insulation tasks, and they continue to be valuable assets for our industry. For that reason, we continue to stress the importance of taping skills and strong product and application knowledge.”

Flex Seal Flex Tape is a super strong, adhesive tape that is designed to bond to various surfaces, creating a waterproof seal. Its unique formulation allows it to stick to almost any surface, whether that be wood, metal, plastic, or even glass. The tape is heavy-duty and is designed to withstand the rigors of both indoor and outdoor environments, making it an essential item in any toolbox.

How to apply self-amalgamating tape

Never forget that the circuit breaker's top always has electricity. The input voltage to the panel can range from 480 volts down to 120 volts or less.

In addition to its practical uses, insulating tape is also popular for creative projects and crafts. Its flexibility and adhesive properties make it a versatile material for various DIY projects. From decorating phone chargers to making colorful bookmarks, insulating tape can add a fun and unique touch to everyday items.

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water waterproof door seal strip.

waterproof door seal strip.In addition to its practical applications, Flex Tape Black is also available in a sleek black color, giving it a modern and stylish look. This makes it a great choice for projects where appearance matters, such as repairing black furniture or appliances.

In a typical tape splice, you’ll tug and pull out the tape, stretching it to just before the breaking point. The tape’s width narrows to about 1/3rd of its original size. The tape’s length increases; your hand travels very quickly up to 20” away from where you started. Quite often you’ll be wrapping in a tight location making this even more difficult. Proper taping techniques are critical to realizing the many performance benefits of rubber tape.