wire mesh gauge 16

Latest articles

wire mesh gauge 16

...

wire mesh gauge 16 【wire mesh gauge 16】

Read Morewire mesh gauge 16

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16The welding core is the metal core of the electrode. In order to ensure the quality of the weld, there are strict regulations on the content of various metal elements in the weld core. In particular, there are strict restrictions on harmful impurities (such as sulfur and phosphorus), and the quality of the weld core metal should be better than that of the base metal. Arc welding cannot be carried out on a smooth rod without a coating. This is because the arc stability is very poor, splashing is very large, and the weld is not well formed. After long-term practice, it is gradually found that the performance of the electrode is greatly improved by coating the welding core with some mineral raw materials (i.e. electrode coating). (1) Ensure stable arc combustion, so that the welding process is normal. (2) Using the gas produced after the drug skin reaction, protect the arc and the molten pool, prevent the harmful gases in the air (such as nitrogen, oxygen, etc.) from invading the molten pool, such as these gases will cause cracks and pores in the welding material, so that the welding can not achieve the ideal effect. (3) After the drug skin is melted, slag is formed, which covers the weld surface to protect the weld metal, make the weld metal slowly cool, help the gas escape, prevent the generation of pores, and improve the structure and performance of the weld. (4) After melting, various metallurgical reactions will be carried out, such as deoxygenation, sulfur removal, phosphorus removal, etc., so as to improve weld quality and reduce alloying element burning loss.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More4, the material requirements of the silk: change wire braid, electric galvanized wire braid, hot galvanized wire braid, first braid after hot plating.

wire mesh gauge 16...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16In the installation of barbed rope, it is easy to cause incomplete stretch caused by winding, and the installation effect is not very good. At this time, it is necessary to use tensioner for stretching.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

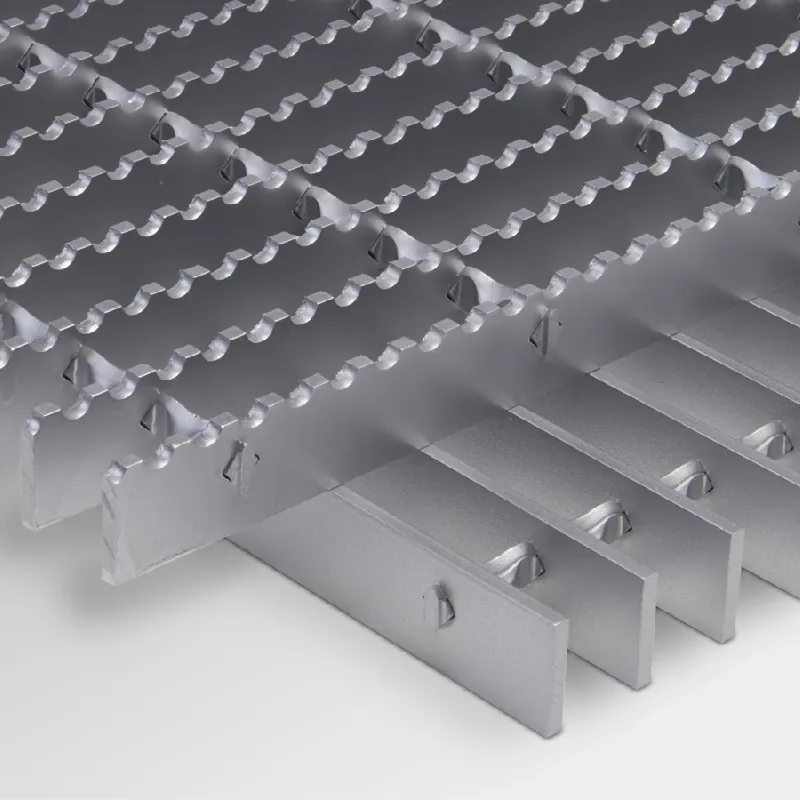

wire mesh gauge 16There are two varieties of steel grid plate is pressure welded steel grid plate and pressure lock steel grid plate, in many people’s eyes, these two products belong to the same variety, in fact, there are still great differences between them in many places.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16

Post time: 19-08-22...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16Flood control and flood information. Can also be used for handicrafts manufacturing, machinery and equipment of transport network mountain beautification network – high strength wire grille (hook flower net, rhombus net) the use of mountain flowers network protection principle, hook flower net, mesh uniform, flat surface, weaving concise, crochet, beautiful generous, wire mesh, mesh with wider picture, diameter of thicker, not easy corrosion, taking a long, and strong usefulness.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16Enclosure to calculate the use of barbed rope, so as to reasonably plan to purchase the amount of barbed rope to facilitate construction.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

wire mesh gauge 16Pay attention to safety in line collection and operation, others without the consent of the monitor, Ben have to get on the bus operation. The reels should be placed lightly, stacked firmly and neatly, not more than 5 reels. Direct contact with acid and alkali must be prohibited. When the acid fog exceeds the specified target of the state, measures should be taken to control it in time, otherwise production is not allowed.

...

wire mesh gauge 16 【wire mesh gauge 16】

Read More

Popular articles

Temporary rust prevention is to prepare for the completion of the mission of the protective layer to be removed. The methods include: cajoling corrosion inhibitors, coating antirust oil, peeling molecular compound plastics, drying air, vacuuming, etc. Change the internal structure of the metal: new chromium, nickel and other alloy elements made of stainless steel, but the alloy is not much, expensive, difficult to produce widespread application.

Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

- The material of wire mesh can choose galvanized wire, stainless steel wire, copper wire, coated wire, lacquer wire, etc., different materials are used in different fields, such as construction, culture, decoration, etc.

In general, the hardness of a metal is often considered to be the resistance of the material to plastic deformation, scratches, wear, or cutting. In the debugging of zinc wire dipping distance, keep the original speed unchanged, according to the time of dipping zinc, the diameter of steel wire, and then estimate the dipping distance. By adjusting the zinc immersion distance, the zinc immersion time of steel wire of various specifications is shortened by 5s on average compared with that before debugging, so that the zinc consumption per ton of steel wire is reduced from 61kg to 59.4kg.

Latest articles

-

The surface coating of galvanized wire can be seen whether the quality of galvanized wire is good or not. If the strength of zinc attached to the wire is very poor, then this galvanized wire do not buy, because this galvanized wire must be poor galvanized wire. High quality galvanized wire in general, the zinc layer attached to the surface of the wire is relatively thick, so when we buy galvanized wire, as long as we look at the thickness of the zinc layer, we can generally judge the quality of galvanized wire.

-

1. Grid structure is simple, beautiful and practical; 2. Easy to transport, installation is not limited by terrain relief; 3. Especially for mountain, slope, multi-curved area adaptability; 4. Medium low price, suitable for large area use. Main market: railway, highway closed net, yard fence, residential guardrail, all kinds of isolation net.

-

Zinc-coated wire is dipped in molten zinc with high production speed and thick but uneven coating. The thickness allowed by the market is 45 microns, the color is dark, the consumption of zinc metal, and the base metal to form infiltration layer, good corrosion resistance, hot dip galvanizing can be maintained for decades in the outdoor environment.

-

The purpose of checking on time is to find problems in time. Users should go to the inspection on time if they can not install the blade barbed rope and ignore it. Local rust should be removed in time and local deformation should be corrected in time, and the service life of the blade barbed rope should be extended.

-

-

Some customers may not use the blade rope immediately when they buy it, some are retail, and some are temporarily not used in site construction. At this time, it is necessary for customers to follow up the characteristics of the blade rope for storage. Because they are afraid of rain, so this is needless to say, and the surface of the packaging is more afraid of the sun, so it is not recommended to prevent outdoor exposure to sunlight will cause the woven bag to become ineffective, resulting in the internal blade of the rope exposed to affect the later use.

Links

- 4’ wide x 10’ long

Stainless Steel Bar Grating is a versatile and durable material commonly used in industrial and commercial applications. This type of grating is highly resistant to corrosion, making it suitable for harsh environments such as chemical plants, food processing facilities, and marine industries. It offers high strength and excellent load-bearing capabilities, making it ideal for pedestrian and vehicular traffic, as well as for various types of flooring, platforms, and walkways. With its open grid construction, stainless steel bar grating allows for easy passage of light, air, and small debris. It also provides a non-slip surface, enhancing safety in wet or slippery conditions. Whether used for drainage, ventilation, or safety flooring, stainless steel bar grating is a reliable and cost-effective solution for a wide range of industrial and commercial applications.

Applications of Shale Shaker Screen Mesh in the Oil and Gas Industry

Nr det kommer til kjp av grating, finnes det et bredt utvalg tilgjengelig for bde private og kommersielle forml. Grating er en essensiell komponent i mange bransjer, inkludert konstruksjon, industri og landbruk. I denne artikkelen vil vi se nrmere p hvorfor grating er s viktig, hvilke typer som er tilgjengelige, og hva man br vurdere nr man skal kjpe grating.

Sonuç

Dále se zubaté ocelové tyče využívají v automobilovém průmyslu, kde se montují do rámů vozidel, čímž přispívají k jejich celkové pevnosti a stabilitě. V oblasti výroby strojů a zařízení se používají jako podpěrné nebo spojovací prvky, které zajišťují vysokou úroveň spolehlivosti a funkčnosti.

The weight of serrated grating can vary significantly based on several factors, including the material used, the thickness of the grating, and the design specifics such as the spacing between the serrations. For instance, stainless steel gratings are typically heavier than their aluminum counterparts due to the difference in material density. A standard length of serrated grating might weigh anywhere from 20 to 60 pounds, depending on these specifications.

serrated grating weight

The Importance of Perimeter Safety Nets Ensuring Workplace Safety

A properly installed trench drain system with a 4% slope can significantly enhance the efficiency of water drainage, promoting a healthier environment and prolonging the lifespan of surrounding structures. It can also contribute to reducing maintenance costs over time, as effective drainage mitigates the likelihood of water damage and related repairs.

विभिन्न उद्योगहरूले प्लास्टिक फ्रेम शेकर स्क्रिनको प्रयोग गर्दा उच्चतम गुणस्तरको मापन र प्रक्रिया का लागि आवश्यक अंशहरूलाई ध्यानमा राख्नुपर्छ। कुनै पनि प्रक्रिया स्थिरता र विश्वसनीयता सुनिश्चित गर्नका लागि नियमित रूपमा स्क्रिनको जाँच र मर्मत गर्नु अत्यन्त आवश्यक छ।

Säkerheten är en annan viktig aspekt av stålristtrappor. De öppna designen minskar risken för halkolyckor, eftersom vatten och skräp snabbt kan rinna bort. Många stålristtrappor är också designade med en särskild yta som ger extra grepp, vilket ytterligare ökar säkerheten för användarna.

갈바니즈 강철 그레팅 현대 건설에서의 중요한 역할갈바니즈 강철 그레팅은 현대 건설 및 산업 현장에서 필수적인 요소로 자리 잡고 있습니다. 이 제품은 높은 내구성과 강도를 자랑하며, 다양한 환경에서 안전한 보행 경로를 제공합니다. 갈바니즈 처리된 그레팅은 철강 재료에 아연을 코팅하여 부식에 대한 저항력을 높인 것입니다. 이러한 특성 때문에, 갈바니즈 강철 그레팅은 특히 외부 환경에서 사용하기에 적합합니다.갈바니즈 강철 그레팅은 주로 발코니, 계단, 다리, 산업 공장 등의 보행로 및 작업 공간에 사용됩니다. 이 제품은 미끄럼 방지 기능이 강화되어 있어, 예기치 못한 사고를 예방하는 데 큰 역할을 합니다. 특히 비가 오는 날이나 습기가 많은 환경에서도 안정적인 발판을 제공하여 안전성을 높이는 데 기여합니다.또한, 갈바니즈 그레팅은 설치가 간편하다는 장점을 가지고 있습니다. 다양한 사이즈와 형상으로 제작할 수 있어, 고객의 요구에 맞춰 맞춤형 솔루션을 제공할 수 있습니다. 이러한 유연성 덕분에, 갈바니즈 강철 그레팅은 다양한 산업에서 매우 널리 사용됩니다. 예를 들어, 화학 공장, 발전소, 운송 센터 등에서 필수적인 요소로 자리 잡고 있습니다.환경 친화적인 측면에서도 갈바니즈 강철 그레팅은 긍정적인 평가를 받고 있습니다. 철강은 100% 재활용이 가능한 소재이기 때문에, 불필요한 자원 낭비를 줄일 수 있습니다. 또한, 갈바니즈 처리는 제품의 수명을 연장시켜주어, 교체 주기를 감소시킵니다. 이는 자원 효율성을 높이며, 전체적인 생태 발자국을 줄이는 데 기여합니다.더욱이, 갈바니즈 강철 그레팅은 경제적입니다. 초기 투자 비용이 상대적으로 낮으면서도, 긴 사용 수명과 낮은 유지 보수를 고려할 때 장기적으로는 매우 경제적인 선택이 됩니다. 이는 많은 기업들이 예산 제약 속에서도 안전하고 효율적인 작업 환경을 유지할 수 있도록 도와줍니다.결론적으로, 갈바니즈 강철 그레팅은 현대 산업 환경에서 안전성과 효율성을 높이는 데 필수적인 요소입니다. 그 내구성과 경제성, 환경적 이점은 많은 기업들에게 매력적으로 다가오고 있습니다. 비록 갈바니즈 강철 그레팅이 산업 환경에서의 역할이 주목받고 있지만, 그 활용 범위는 앞으로도 계속 확대될 것으로 기대됩니다. 따라서, 이 제품을 활용한 다양한 솔루션이 앞으로 더욱 중요해질 것입니다.

galvanised walkway grating

Cleanliness.

Ang helideck ay isang platform na idinisenyo upang pagtapakan ng mga helicopter. Sa mga ganitong uri ng operasyon, napakahalaga ng mga sistema ng seguridad, at dito pumapasok ang chain link mesh. Ang mesh ay gawa sa matibay na materyales na kayang tumagal sa matinding kondisyon ng panahon at mataas na pagkarga. Ito ay nakakatulong na hindi lamang sa pagpigil ng mga helicopter na madulas sa helideck, kundi nagdadala rin ito ng karagdagang suporta at tibay sa kabuuang estruktura ng helideck.

في الختام، تُعتبر تغطيات المصرف الخندقي استثمارًا ذكيًا يُساهم في إدارة المياه بشكل فعّال مع تحسين جماليات المنطقة وزيادة السلامة العامة. إن اختيار النوعية المناسبة من التغطيات يُمكن أن يؤدي إلى فوائد متعددة، تبدأ من تقليل الفيضانات إلى تحسين الصورة العامة للمكان. لذا، من المهم التفكير في استخدام تغطيات المصرف الخندقي كجزء من أي خطة تصميم حضري أو بيئي. إن تطبيقات هذه التغطيات واسعة ومتنوعة، مما يجعلها خيارًا مثاليًا لمختلف الأنشطة والمشاريع.

تعتبر مشقّات الأرضيات من العناصر الأساسية في التصميم المعماري الحديث. تلعب هذه الأنظمة دورًا هامًا في تحقيق التوازن بين الجمالية والوظيفة في المساحات المختلفة. فمشقّات الأرضيات، المصنوعة عادةً من الصلب أو الألمنيوم أو الألياف الزجاجية، توفر حلولًا فعّالة لدعم الهيكل وتقليل الوزن، بينما توفر أيضًا مساحات آمنة ومريحة للناس.

When selecting a supplier, it is essential to consider the variety of products they offer. Aluminum grating comes in various styles, including bar grating, plank grating, and expanded metal grating, each suited for different applications. A good supplier should have a diverse range of options, allowing businesses to find the perfect solution for their specific needs. Moreover, suppliers that offer customized solutions can be particularly valuable, enabling clients to obtain tailored products that fit unique specifications.

aluminum grating suppliers

Il trattamento satinato dona all'acciaio inox un aspetto sobrio e raffinato, capace di adattarsi a qualsiasi contesto, sia esso residenziale o commerciale. A differenza delle finiture lucide, che possono apparire troppo brillanti e facilmente soggette a macchie e impronte digitali, l'acciaio inox satinato ha il pregio di nascondere le imperfezioni e le impronte, mantenendo l'estetica pulita e ordinata nel tempo. Questa caratteristica è particolarmente apprezzata in ambienti come cucine e bagni, dove è fondamentale avere superfici facili da pulire e che richiedono poca manutenzione.

Bruksområder for galvanisert gitter er mange. Det brukes ofte i industriell konstruktion for trapper, plattformer og gangveier, hvor det gir både sikkerhet og stabilitet. Det er også et populært valg for sikkerhetsgaller og avskjæringer, der det er viktig å opprettholde god synlighet samtidig som man hindrer tilgang til farlige områder. I tillegg brukes galvanisert gitter i landbruket, for eksempel som gulv i husdyrhold, der det gir god lufting og drenering.

3. Versatility Hot dip galvanized grating can be fabricated into various shapes and sizes to fit specific applications. This versatility allows it to be used in walkways, platforms, stair treads, and even architectural features.

1. Vattenavledning En av de största fördelarna med golvristor är deras förmåga att hantera vatten. De hjälper till att förhindra vattenansamlingar och minskar risken för halkolyckor, vilket gör dem avgörande i miljöer där fukt är ett problem.

The thickness of steel grating, typically measured in millimeters or inches, plays a critical role in its load-bearing capacity and overall durability. Thicker grating can support more weight and withstand more significant impacts, making it vital in settings where heavy equipment and foot traffic occur. For example, a thicker grating is often used in loading docks or industrial warehouses, where heavy machinery operates regularly.

Benefits of Metal Mesh Gratings

metal mesh grating

Ståljernrist En Ideel Løsning til Byggeri og Infrastruktur

The production of hot dip galvanized steel grating involves several stages. Initially, raw steel bars are shaped into a grid pattern, forming the grating itself. This grid design allows for efficient drainage and visibility, making it ideal for numerous applications. The next crucial step is the hot dip galvanizing process, where the steel grating is submerged in a molten zinc bath at high temperatures. This process creates a robust protective layer of zinc, which adheres to the steel surface through a metallurgical reaction, providing long-lasting protection against corrosion and wear.

Stainless steel walkway mesh has become a popular choice in various industries due to its remarkable strength, durability, and aesthetic appeal. This versatile material is engineered to meet the demands of both heavy-duty applications and light pedestrian traffic, making it ideal for diverse environments such as industrial facilities, commercial spaces, and outdoor attractions.

Material Types and Their Costs

यसैले, हेलीडेक नेट अब केवल एक संरचना मात्र होइन, यो एउटा सशक्त नेटवर्क हो जुन हवाई उडानलाई प्रभावकारी, सुरक्षित र समृद्ध बनाउनका लागि आवश्यक छ। यसका माध्यमबाट, विभिन्न उद्योगहरूको पारिस्थितिकी प्रणालीमा क्रान्ति ल्याउने क्षमता छ, र भविष्यमा हवाई सेवा र आपतकालीन प्रतिक्रिया प्रणालीलाई अझ प्रभावकारी बनाउन मद्दत गर्ने आशा गरिएको छ।

Industry Peer Recommendations of Shale Shaker Screens

5. Versatility Open floor grating is incredibly versatile and can be used in various applications. It is commonly found in platforms, stairways, and catwalks, as well as in manufacturing plants, chemical facilities, and water treatment plants.

En outre, l’acier inoxydable est un matériau écologique. Sa fabrication et son recyclage génèrent moins de déchets par rapport à d'autres métaux. Cela en fait un choix de construction responsable qui répond aux préoccupations environnementales modernes. De plus, la longévité de l’acier inoxydable contribue à une empreinte carbone réduite sur le long terme, car il ne nécessite pas d’être remplacé aussi fréquemment que d’autres matériaux.

4. Durability Many trench drain grates are constructed from heavy-duty materials designed to withstand harsh weather conditions, high foot traffic, and vehicular loads. This durability ensures longevity and reduces maintenance costs over time.

The designation 19% 204% refers to specific design measurements that define the spacing and sizing of the bars. The first number, 19%, indicates the spacing between the bars. This configuration allows for certain loads to be supported while maintaining adequate airflow and drainage. The second number, 204%, usually refers to the load-bearing capabilities and the overall strength of the grating.

トレンチドレイングレートは、環境保護の観点からも重要です。適切な排水は、河川や湖沼への過剰な雨水流出を減少させ、水質を保つ助けとなります。都市の雨水管理は、持続可能な開発に欠かせない要素であり、トレンチドレインはその中心的な役割を果たしています。

Understanding 19w2% Grating An Essential Concept in Optical Engineering

Sammenfattende tilbyder stålristgulve en række fordele, herunder styrke, sikkerhed, holdbarhed og bæredygtighed. Deres alsidighed gør dem til en fremragende valg for enhver, der ønsker et pålideligt og effektivt gulv, der kan stå imod tidens tand og de udfordringer, der følger med forskellige arbejdspladser. Med stålristgulve får man ikke bare et gulv, men en langvarig investering i kvalitet og sikkerhed.

La grille de drainage de tranchée à 4%

Overall, the advantages of using carbon steel bar grating for heavy loads make it a highly desirable option for a wide range of industrial and architectural applications. Its strength, versatility, and ability to meet specific requirements make it a reliable and durable choice for demanding environments.

हेलीडेक नेट, जहाज र हेलीकोप्टरका लागि विशेष रूपमा डिजाइन गरिएका हेलीप्याडहरूमा उडानको एक महत्वपूर्ण पहलु हो। यी नेटवर्कहरूले समुद्री र अन्य दुर्गम स्थानमा हवाई ट्राफिकलाई सुरक्षित र प्रभावकारी रूपमा व्यवस्थापन गर्नमा मद्दत गर्छन्। विशेष रूपमा नीलाम र सागरका क्षेत्रमा काम गर्ने विभिन्न प्रकारका व्यवसायहरूको लागि यी नेटवर्कहरूको उपयोग अत्यन्त आवश्यक छ।

Composite Screens: Composite screens are made of a combination of materials, such as metal and synthetic fibers, to provide enhanced durability and separation efficiency. These screens are ideal for drilling operations in harsh environments or with abrasive drilling fluids. Composite screens offer improved resistance to wear and tear, ensuring longer service life.

Sonuç olaraq, alüminium ızgara döşəmələri, müasir inşaat və dizayn sahəsində əhəmiyyətli bir seçimdir. Onların davamlılığı, estetik görünüşü, yüngüllüyü və təhlükəsizlik xüsusiyyətləri, onları fərqli sahələrdə geniş istifadə üçün ideal hala gətirir. Gələcəkdə bu materialın daha da populyar olacağı gözlənilir, çünki daha çox layihədə üstünlükləri nəzərə alınır.