metal wire mesh screen

Latest articles

metal wire mesh screenWet air in rain and snow climate, steel mesh sheet exposed, easy to rust, to avoid affecting the use of steel mesh, it is necessary to carry out simple rust prevention treatment, of course, slight rust float will not affect the use of steel mesh. Common network site storage, rainy days, heavy snow, rainy days and rainy days, how to better save the steel mesh, this is a lot of friends need to consider.

...

metal wire mesh screen 【metal wire mesh screen】

Read Moremetal wire mesh screen

...

metal wire mesh screen 【metal wire mesh screen】

Read More

metal wire mesh screenIn moist air, a dense basic zinc carbonate film forms on the surface of zinc. Zinc coating belongs to the anodic coating, it is mainly used to prevent the corrosion of steel, its protective performance and the thickness of the coating is very important. The protective and decorative properties of zinc coating can be improved significantly after passivation treatment, dyeing or coating with light protection agent.

...

metal wire mesh screen 【metal wire mesh screen】

Read MoreHexagonal cage has a wide range of applications, with the progress of science and technology, has been extended to the major hydraulic, civil engineering. Geotechnical engineering and other projects. In hydraulic hexagonal cage in river construction from closed utility, think appropriate and the use of hexagonal cage to fill stone, fixed river, can be used to avoid river erosion brought water and soil loss. In civil engineering projects, hexagonal cage that is suitable and the use of similar particle size volume particles to fill, mesh wall is formed between the cage, which is the stone cage retaining wall.

metal wire mesh screen...

metal wire mesh screen 【metal wire mesh screen】

Read More

metal wire mesh screenProduct features: strong structure, flat surface, with good corrosion resistance, oxidation resistance. The material of small hexagonal mesh is the same as that of other hexagonal mesh, which is generally made of low carbon steel wire, stainless steel wire and galvanized steel wire as raw materials by the hexagonal mesh machine.

...

metal wire mesh screen 【metal wire mesh screen】

Read Moremetal wire mesh screen

...

metal wire mesh screen 【metal wire mesh screen】

Read Moremetal wire mesh screen

...

metal wire mesh screen 【metal wire mesh screen】

Read More

metal wire mesh screenThere is no adhesion test of powder spraying or fluorocarbon spraying on packaged galvanized wire, but there are two points for reference: first, in sealed or air-free environment, non-metallic volatiles can corrode zinc coating; Second, zinc at higher than 230 degrees (c) will cause the matrix metal brittle. And powder spraying and fluorocarbon spraying are to be baked at a higher temperature and in a sealed environment, causing rapid corrosion of zinc, resulting in loose corrosion film resulting in coating adhesion decline, and even lead to (matrix) steel wire brittle situation may exist.

...

metal wire mesh screen 【metal wire mesh screen】

Read More

metal wire mesh screen

Post time: 24-02-23...

metal wire mesh screen 【metal wire mesh screen】

Read Moremetal wire mesh screen

...

metal wire mesh screen 【metal wire mesh screen】

Read More

Popular articles

Post time: 11-07-22- Professional materials in use can meet the needs of most consumers for materials, and the quality of these products is certainly to withstand the test, so if you really can not make up your mind, choose what kind of barbed rope, it is recommended to choose the best blade barbed rope.

Spring steel wire should have high tensile strength, elastic limit, endurance and fatigue strength, and resistance to impact and oscillation. The strength and endurance objectives, especially to prevent the occurrence of modification cracks, are the key to the consumption of spring wire. The inner quality and outer quality of the wire rod directly affect the function of the wire.

Post time: 20-03-23

Latest articles

-

-

Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

-

There are two kinds of use, namely slope protection hook mesh, coal hook mesh, mining hook mesh, coal mine support network, roadway support network. The height of the outer rail of the pavement or seat belt should not be less than 1.10 m. The net distance between balustrade members shall not be greater than 140 mm, and horizontal rail shall not be used. Hook mesh planning is necessary to be safe and reliable, anchor should be installed on the basis of the railings, its strength should meet the requirements of the standard.

-

-

Galvanized iron wire has tolerance and elasticity, the amount of zinc can reach 300 g/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other fields.

-

Galvanized wire coating has galvanized, aluminum, nylon or plastic coating. Zinc plating is divided into thin coating after steel wire plating and thick coating after steel wire drawing. The mechanical properties of thick coating are lower than that of smooth steel wire rope, and it is suitable for use in serious corrosive environment. Aluminized wire rope it is more resistant to corrosion, wear resistance, heat resistance than galvanized wire rope, using the method of production after the first plating. The wire rope coated with nylon or plastic is divided into two kinds: coated rope and coated rope.

Links

The adoption of industrial zig zag embroidery machines brings numerous benefits to textile manufacturers. Firstly, the ability to create complex designs quickly while maintaining high quality allows businesses to stay competitive in the fast-paced fashion industry. Customers increasingly demand unique and personalized items, and these machines enable manufacturers to meet that demand efficiently.

- Overall, single needle stitching is a valuable technique that is used in a wide range of industries, from fashion to upholstery. Its strength, durability, and versatility make it a popular choice for creating high-quality garments and products. While mastering this technique may require practice and patience, the results are well worth the effort, producing beautifully finished items that will stand the test of time.

As you contemplate the choice between a handheld sewing machine and a heavy-duty one, remember that your decision should align with your sewing goals, budget, and the types of projects you aspire to tackle. Consider the features that matter most to you, the learning curve you're comfortable with, and the accessories that will enhance your sewing experience.

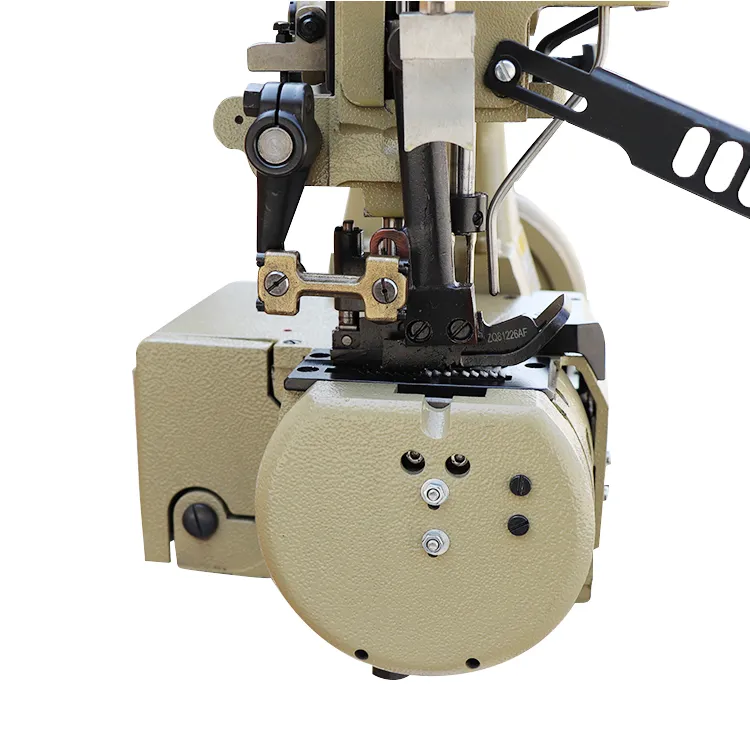

In today’s fast-paced textile and garment industry, efficiency and precision are of utmost importance. Among the myriad of sewing machines available, the high-speed overlock sewing machine stands out as an essential tool for both home sewers and industrial manufacturers. This innovative device not only enhances the speed of sewing operations but also improves the quality of seam finishing, making it a vital asset for modern textile production.

Advantages of Heavy-Duty Sewing Machines

As sustainability becomes increasingly important in manufacturing, the development of plastic bag closer machines also evolves. Many manufacturers are investing in technology that utilizes eco-friendly materials and processes. There is a growing trend towards machines that can seal bioplastics or compostable bags, catering to environmentally conscious consumers and businesses.

The Challenge of Thick Fabrics

- Upholstery Furniture makers rely on these machines to stitch heavy upholstery fabrics with precision, ensuring a professional finish.

Additionally, the rise of interest in DIY projects and home crafting has resulted in an increased demand for user-friendly tools like needle threaders. As more people engage in sewing as a relaxing hobby or a sustainable alternative to fast fashion, threaders have become more than just a convenience; they symbolize an entry point into a world of creativity and self-sufficiency. Craft stores and online marketplaces now offer a variety of styles and functionalities, ensuring that there is a perfect threader for everyone.

What is a Walking Foot Sewing Machine?

Applications in the Sewing Industry

At its core, the zigzag foot is designed to perform zigzag stitches, which are characterized by their zigzag pattern, as opposed to straight stitches. This stitching technique enables a variety of applications, from sewing knits and stretch fabrics to adding decorative details and finishing raw edges. The aggressive movement of the needle back and forth allows for exceptional versatility, making the zigzag foot indispensable for uniting cloth pieces, creating hems, and adding decorative embellishments.

The Zig Zag Dressmaker Sewing Machine A Craftsperson’s Essential Tool

The Floating Foot Sewing Machine Revolutionizing the Craft of Sewing

5. Walking Foot Mechanism A walking foot is a great addition for sewing leather as it helps to evenly feed the material through the machine, preventing slipping and ensuring neat seams.

heavy duty leather sewing machine for sale

The Features of Zig Zag Machines