wire mesh screens suppliers

Latest articles

wire mesh screens suppliers3. The structure of the dog cage should be reasonable

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read More

wire mesh screens suppliersAnnealing wire is widely used because it has a good elasticity and flexibility, in the annealing process can be good control of its hardness, it is mainly made of iron wire, more often used in the construction industry binding wire use. In the production of the wire factory, annealing wire will be processed according to the properties of the material, according to the needs of different to change its hardness degree, can make it has more advantages, can reduce the consumption of metal, reduce the cost of production.

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read More

wire mesh screens suppliersThe diameter of cold-drawn wire should conform to the contract, check whether the amount of zinc meets the requirements of the contract, check the tensile strength, and ask the factory to provide the corresponding inspection report. The wire factory introduces that the weight of a single coil of wire of different specifications should not be lower than the volume weight required by the contract, and record the value. No contacts are generated for each reel of wire. If there are contacts, no more than three contacts are generated for each reel. Each contact should be smooth surface treatment, the wire can not be pulled off from the contact, in line with customer packaging requirements.

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read Morewire mesh screens suppliers

...

wire mesh screens suppliers 【wire mesh screens suppliers】

Read More

Popular articles

Wire mesh production of general selection of low carbon wire, after fine and accurate active welding equipment processing, the selection of galvanized process surface treatment. After the completion of the product, the net surface is smooth and regular, good integrity, strong and consolidated, even if part of the choice or pressure will not appear lax phenomenon.

Hexagonal net structure can be used for slope support, excavation, rock face net mine support form, slope vegetation (green color), railway road isolation block, it can be made into a cage, pad, used for river, flood dam and seawall erosion protection and reservoir, river closed cage. Driving and guiding rivers and waterlogging disasters are major water erosion damage to rivers, resulting in flooding, resulting in significant loss of property and loss of water and soil. Because of this, in dealing with these problems, the application of the living grid structure becomes a solution plan, which makes it possible to protect the shore forever.

If the blade barbed rope produced by the barbed rope factory wants to be made into a straight line, it can’t be made too long because of the constraints of logistics.

- 5. The bird cage should be sprayed with transparent wood environmental protection paint every 1-2 years. This protects the cage’s skeleton from the effects of weathering.

Latest articles

-

-

Paint on the galvanized layer, the binding force between each other and the baking temperature of the paint has a great relationship, after galvanized coating alkyd paint, adhesion is no problem. Galvanized amino paint, paint adhesion is not good. Do two bottom two surface, adhesion is ok, if the two bottom two surface to two bottom three surface, that is, more paint, more baking once, again test adhesion is very poor, poor to the paint from the galvanized layer of pieces torn off.

-

-

Galvanized hexagonal mesh is a kind of galvanized metal wire mesh, the mesh shape is hexagonal.

-

-

Links

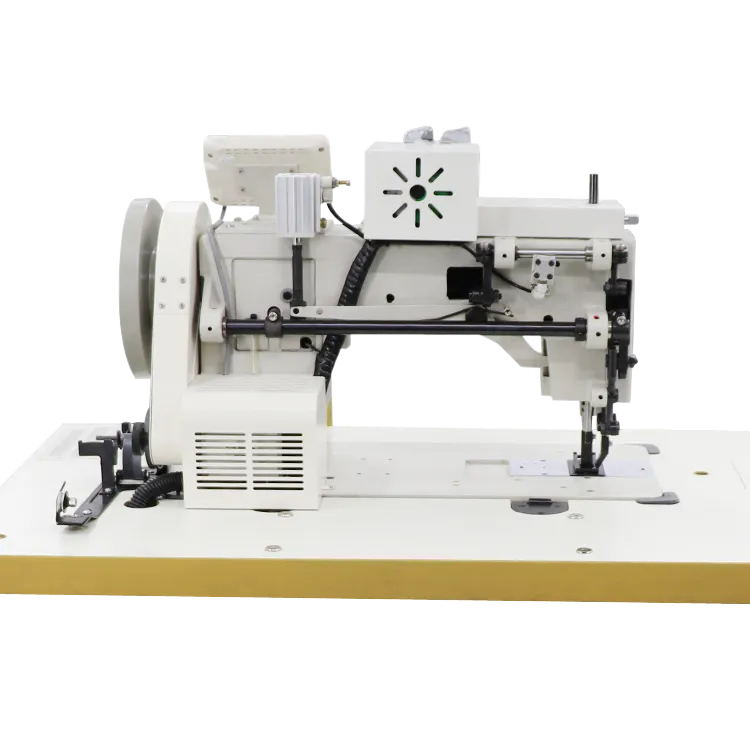

2. Walking Foot Mechanism One of the most important features to look for in an upholstery machine is a walking foot. This mechanism helps to evenly feed multiple layers of fabric through the machine, preventing shifting and ensuring that stitches are uniform. This is particularly valuable when working with thick or slippery materials.