The twill weave is characterized by an over two, under two pattern. It leaves behind a distinctly diagonal design and is typically wrinkle-resistant due to the thickness. Twill woven sheets are prone to shrink more than those with a sateen weave but are also often times more affordable.

powder coated welded wire panels

Latest articles

powder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read More

powder coated welded wire panels

Post time: 31-05-23...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read More

powder coated welded wire panelsAccording to the galvanized iron wire manufacturer, galvanized iron wire is the selection of excellent low carbon steel, through drawing forming, pickling rust removal, high temperature annealing, hot dip galvanized, cooling and other processes. Galvanized iron wire should pay attention to the following points in the use process:

...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read More③ The galvanized iron wire shall not be damaged when it is tightened.

powder coated welded wire panels...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read Morepowder coated welded wire panels

...

powder coated welded wire panels 【powder coated welded wire panels】

Read More

Popular articles

- There are two kinds of electrochemical protection. One is to connect a piece of metal that is slightly more vivid than it. For example, ships and ships will be inlaid with zinc blocks. The second is to connect the negative terminal of the power supply, such as iron and steel river locks are often connected with the negative terminal of the power supply, through the negative terminal. Its methods include: metal cover film such as electroplating, organic coating such as paint, transformation layer such as orchid or black, new elements to change the metal structure.

Post time: 13-06-24Now most people want to choose a few when choosing barbed wire material better thorn rope, but the special barbed wire the better, not right, it is important to choose which model is most suited to their own thorn rope,, although is very simple product, but in the use of these products are for specific situation is different, and has a different effect, Maybe now consumers do not have too much concept of blade barbed rope, in fact, such barbed rope products have a higher safety factor. In addition, there are also more and more barbed rope, dazzling reasons, here is an example to illustrate the choice of special barbed rope.

- Because the anti-aging and anti-corrosion ability of zinc-aluminum alloy wire is much higher than galvanized barbed rope, it is widely used in all kinds of places where personnel are scarce and lack of maintenance ability, and is used for island protection in coastal areas

Latest articles

-

-

-

-

-

There are generally PVC plastic coating on the cattle net is in the original galvanized steel wire on the cover of a layer of dark green or gray plastic mold, to avoid the corrosion of wire diameter, is conducive to the progress of the anti-rust function of wire diameter. So the better the raw material, the higher the price. Zinc aluminum alloy cattle net is the best metal net on the market, the price is higher than hot dip galvanized raw materials. The service life is about 80-90 years, with excellent anti-corrosion function.

-

Razor blade barbed rope has been widely used in military sites, prisons, government agencies, banks in the world. The walls of living quarters, private homes, villas, fences, doors and Windows, highways, railway guardrail and border lines and other protection and security.

Links

One of the key factors in finding good quality affordable bedding is to work with a reputable bedding supplier whose products come from reliable bedding factories. These bedding suppliers often have access to a variety of bedding designs and materials, allowing you to choose the perfect great quality bedding to suit your personal style and preferences.

A fitted sheet has pocket corners and elastic on all four sides to provide a snug fit to your mattress. These sheets are designed to keep from bunching and shifting while you sleep.

Microfiber is a good option if your budget is a little tighter and, as it's wrinkle-resistant, it's perfect if you're not a fan of ironing. However, it might not be the first choice if you're looking for an upscale aesthetic.

2. Bamboo

Lulu & Georgia's Aja Tilghman says: 'Bedsheet material choice really depends on preference. Linen is a great light and airy option that is exceptionally versatile and adapts to all seasons - keeping you warm in the winter and cool in the summer. It gets softer over time while maintaining its beautiful natural elegance.

Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover

Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover Comforter inserts are designed to be used with a duvet cover and provide a layer of insulation between you and the cover comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs.

comfy duvet insert. They are typically filled with down or synthetic materials, which provide excellent warmth and comfort. Comforter inserts are also available in a wide range of sizes and weights, so you can choose the perfect one for your needs.

Bed Sheets Ultimate Guide — What Are the Best Types, Materials, and Weaves?

Egyptian cotton comes from a different plant (Gossypium Barbadense) to regular cotton, which is why it has different and superior properties. Egyptian cotton has extra long fibres which produce thread or yarns that are thinner and smaller in diameter yet stronger than other cottons. This means that the threads can be woven into a luxurious durable fabric that no other cotton can match.

The higher the fill power, the better the insulation and durability The higher the fill power, the better the insulation and durability

The higher the fill power, the better the insulation and durability The higher the fill power, the better the insulation and durability big duvet insert. For a big duvet insert, a fill power of 500-700 is ideal for providing ample warmth without being too heavy.

big duvet insert. For a big duvet insert, a fill power of 500-700 is ideal for providing ample warmth without being too heavy. The result is a set of sheets that provide a comfortable sleeping surface, stay fresh-looking for longer periods, and require less maintenance The result is a set of sheets that provide a comfortable sleeping surface, stay fresh-looking for longer periods, and require less maintenance

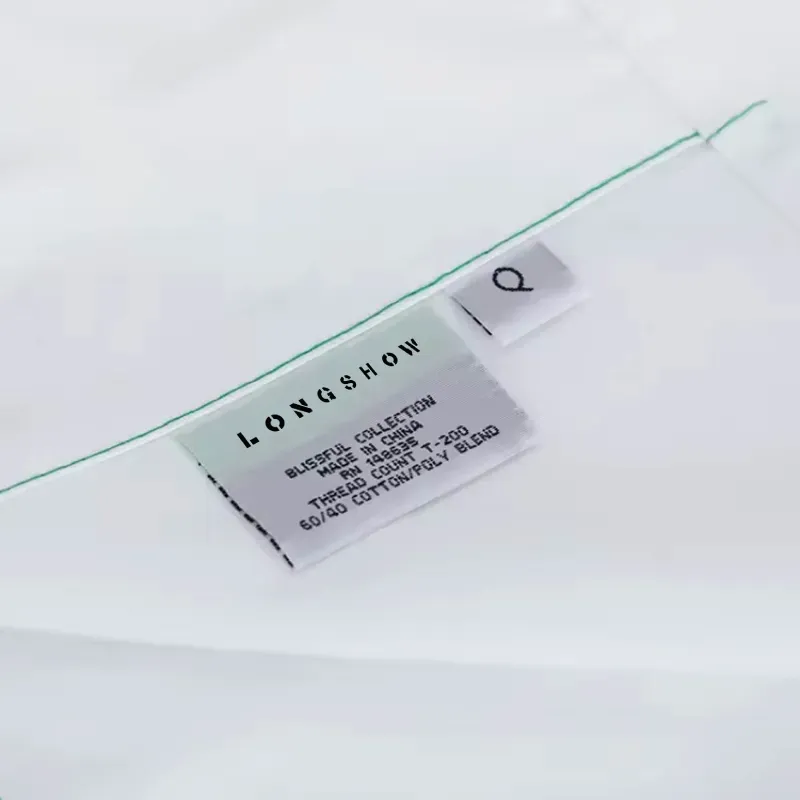

The result is a set of sheets that provide a comfortable sleeping surface, stay fresh-looking for longer periods, and require less maintenance The result is a set of sheets that provide a comfortable sleeping surface, stay fresh-looking for longer periods, and require less maintenance cotton polyester blend sheet sets.

cotton polyester blend sheet sets.What's The Difference Between Bed Linen And Fitted Sheets?

This not only prolongs the lifespan of your expensive mattress topper but also saves you money in the long run by reducing the frequency of replacements This not only prolongs the lifespan of your expensive mattress topper but also saves you money in the long run by reducing the frequency of replacements

This not only prolongs the lifespan of your expensive mattress topper but also saves you money in the long run by reducing the frequency of replacements This not only prolongs the lifespan of your expensive mattress topper but also saves you money in the long run by reducing the frequency of replacements mattress topper sheet.

mattress topper sheet.Percale

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey hotel standard bed sheets. Moreover, the aesthetic appeal of the bedding cannot be underestimated. Well-presented bed sheets in neutral colors with subtle, tasteful patterns can enhance the overall ambiance of the room, contributing to a sense of luxury and refinement.

hotel standard bed sheets. Moreover, the aesthetic appeal of the bedding cannot be underestimated. Well-presented bed sheets in neutral colors with subtle, tasteful patterns can enhance the overall ambiance of the room, contributing to a sense of luxury and refinement. Some premium brands may offer even larger sizes to cater to the preferences of their clientele Some premium brands may offer even larger sizes to cater to the preferences of their clientele

Some premium brands may offer even larger sizes to cater to the preferences of their clientele Some premium brands may offer even larger sizes to cater to the preferences of their clientele average size of a bath sheet. High-quality bath sheets are usually made from Egyptian cotton or Turkish cotton, known for their long fibers, resulting in a soft, absorbent, and durable towel.

average size of a bath sheet. High-quality bath sheets are usually made from Egyptian cotton or Turkish cotton, known for their long fibers, resulting in a soft, absorbent, and durable towel.