100 gsm barbed wire

Latest articles

100 gsm barbed wire

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

100 gsm barbed wireIn our daily life, what we can bend with our hands is basically galvanized iron wire, not steel wire. It has a high zinc content, which ensures excellent toughness and resilience, as well as ultra-high corrosion resistance, which can be maintained in outdoor environments for decades. There are many practical galvanized iron wire, such as strong reliability, galvanized layer and iron together, forming a special metallurgical structure, in the use and transportation process, can ensure that it will not be mechanical damage.

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

100 gsm barbed wire

Post time: 09-09-22...

100 gsm barbed wire 【100 gsm barbed wire】

Read MorePacking and binding galvanized wire is in the liquid state of zinc, after a messy physical and chemical effect, not only on the steel plated thick pure zinc layer, and also generate a zinc-iron alloy layer. This plating method, not only has the characteristics of corrosion resistance of galvanized wire, and because of the zinc iron alloy layer. It also has strong corrosion resistance that can not be compared with electric galvanizing. Therefore, this plating method is particularly suitable for a variety of strong acid, alkali fog and other strong corrosive environment.

100 gsm barbed wire...

100 gsm barbed wire 【100 gsm barbed wire】

Read MoreIn addition, galvanized silk manufacturers can be required to passivation treatment after zinc immersion, after passivation treatment of zinc has a better anti-discoloration effect, can effectively extend the time of discoloration, the combination of the two, discoloration should be able to solve.

100 gsm barbed wire...

100 gsm barbed wire 【100 gsm barbed wire】

Read More100 gsm barbed wire

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

100 gsm barbed wireThe diameter of cold-drawn wire should conform to the contract, check whether the amount of zinc meets the requirements of the contract, check the tensile strength, and ask the factory to provide the corresponding inspection report. The wire factory introduces that the weight of a single coil of wire of different specifications should not be lower than the volume weight required by the contract, and record the value. No contacts are generated for each reel of wire. If there are contacts, no more than three contacts are generated for each reel. Each contact should be smooth surface treatment, the wire can not be pulled off from the contact, in line with customer packaging requirements.

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More100 gsm barbed wire

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

100 gsm barbed wireThe distance between the adjacent two thorn rope installation do not know whether you have noticed? Careful observation can find that its spacing is not the same, the thorn rope factory for customer consultation when asking the installation height of the reason.

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

100 gsm barbed wireContinuous production does not need heating, but needs cooling. Cooling can be in the groove side row thin wall plastic pipe, through the flow of tap water cooling, can also be used as a titanium pipe temperature control device. In the process of composite electroplating galvanized wire, the plating solution must be stirred to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc.

...

100 gsm barbed wire 【100 gsm barbed wire】

Read More

Popular articles

The price of galvanized iron wire is relatively low, but the corrosion resistance is excellent, so it is favored by many screen businesses. In the production process of galvanized iron wire, first of all, we should check the equipment to see if there are any problems, and then we should look at the galvanized process, whether there are factors that cause product discoloration. If these problems do not exist, or some of them occur on the same equipment, and some are normal, then we should consider the problem of raw materials at this time.

Through the maintenance of galvanized wire, it can not only greatly prolong its service life, but also improve its efficiency in the daily use process. Because the labeled electrode potential of zinc is -0.762v, which is negative than iron, zinc becomes the anode when the galvanic cell is formed after being corroded by the medium. It itself is dissolved to protect the steel matrix. The duration of the protection of galvanized wire layer has a great relationship with the thickness.

Large hexagonal mesh called stone cage net, is mainly used for mountain protection, hydraulic construction and so on. Small wire hexagonal mesh is used as a good material for breeding, will twist twist hexagonal mesh in the welded iron frame on the hexagonal mesh welding into chicken coop, pigeon cage, rabbit cage cage cage, hexagonal mesh is the best material for breeding with a net.

- In this temperature range, the zinc solution is severely corroded to the workpiece and the zinc pot, and the iron is lost at 560 degrees Celsius to add obviously, and the zinc will be the iron substrate above 660 degrees Celsius, zinc slag will be added quickly, plating cannot be used. Therefore, electroplating is carried out in the range of 430~450 degrees Celsius.

Post time: 01-09-22

Latest articles

-

Both sides of the galvanized welding net exposed can not be more than 2mm, so as to be qualified. And in the welding mesh of each warp and weft wire cross place, must be welded very firm, and if you want to welding very firm, both sides must have some warp and weft wire out, and the length must be controlled within two millimeters. From the mesh distribution is not uniform, galvanized is not uniform, but also to see whether the welding mesh is qualified standards.

-

-

Post time: 29-09-22 -

-

-

Links

What is a Ceiling Grid Tee?

1. HVAC Systems These access panels offer a convenient way to reach ductwork, filters, and other components of heating, ventilation, and air conditioning systems without requiring extensive demolition or remodeling.

The installation of metal access hatches requires careful planning and execution. It is essential to identify the best location that facilitates easy access while ensuring that the hatch does not compromise the structural integrity or design of the ceiling. Proper installation involves attention to detail, including ensuring that the hatch is correctly aligned and securely mounted. This step is critical, as poorly installed hatches can lead to structural weaknesses and might require frequent repairs.

Easy Installation and Maintenance

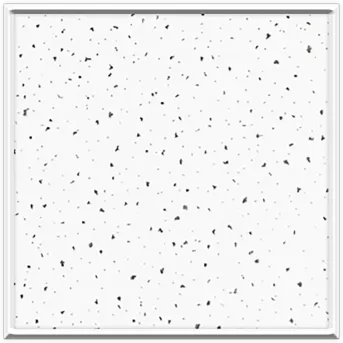

- Healthcare Facilities In hospitals and clinics, the combination of fire resistance, mold resistance, and sound absorption makes mineral fiber ceiling boards a practical choice for ensuring patient comfort and safety.

Using a drywall saw or utility knife, carefully cut along the marked outline. Make sure to wear safety glasses and a dust mask to protect yourself from debris. Take your time during this step, as a clean cut will ensure a better fit for the access panel.

how to install a ceiling access panel

Installation and Maintenance

1. Locate the Access Area

Installation Practices

Circular Ceiling Access Panels An Overview

Types of Ceiling Tile Access Panels

3. Easy Maintenance One of the standout features of PVC is its ease of maintenance. The ceiling grids can be easily cleaned with a damp cloth, and any stains can be removed with the right cleaning solutions. This low-maintenance characteristic is a significant advantage over other materials that require more rigorous upkeep.

Considerations When Installing Hatch Ceilings

In addition to their visual and practical benefits, concealed spline ceiling tiles can also contribute to improved acoustic performance. Certain tile designs incorporate sound-absorbing materials that help to reduce noise levels in bustling environments. This feature is especially critical in spaces such as offices, restaurants, and educational facilities, where conducive acoustics can enhance productivity and comfort.

PVC Laminated Ceiling Panels A Modern Choice for Interior Design

Service and Quality

What Are AC Ceiling Access Panels?

3. Vinyl Coated Grid Covers These offer durability and come in various colors, ensuring they can resist scratches and wear. They are particularly suited for commercial environments where longevity is important.

Energy Efficiency: Mineral Fiber Tiles Ceiling is designed to improve energy efficiency by reducing the amount of heat that escapes through the ceiling.

In conclusion, mineral fiber board is a versatile and essential material in modern construction and insulation practices. Its unique combination of thermal insulation, sound absorption, fire resistance, and sustainability makes it an invaluable asset to architects, builders, and homeowners alike. As the demand for energy-efficient and eco-friendly building materials continues to rise, mineral fiber boards are likely to play an increasingly prominent role in the construction industry. Whether used in residential buildings or large commercial projects, mineral fiber boards contribute to a safe, comfortable, and sustainable living environment.

The Versatile Application of Ceiling T Bar Clips

Installation and maintenance are other factors to consider. Proper installation is crucial to ensure that the tiles are securely fitted into the suspension system, preventing sagging or misalignment. Although mineral fibre tiles are relatively low maintenance, any stains or dirt accumulate over time may require cleaning or replacement.

4. Aesthetic Appeal Drop ceilings offer a polished and professional look, enhancing the overall ambiance of the space.

In conclusion, rigid mineral wool board is a fundamental building material that brings together energy efficiency, fire resistance, sound absorption, and environmental sustainability. As the demand for eco-friendly and effective insulation solutions continues to grow, mineral wool stands out as a reliable choice for modern construction. Its properties not only enhance the quality of buildings but also contribute to creating a sustainable future, making it an essential component in today’s construction landscape. Whether for new builds or renovations, rigid mineral wool board is undoubtedly a material that warrants attention.

A hanging ceiling tile grid is a suspended system made of metal or lightweight materials that is installed below the existing ceiling. This grid framework supports ceiling tiles, allowing them to create a flat, uniform ceiling surface. The grid consists of main runners, cross tees, and wall angles, all strategically arranged to hold the tiles securely in place. These grids can be adjusted to accommodate different tile sizes and configurations, making them highly versatile.

Black Ceiling Tiles with White Grid A Modern Design Choice

Suspended ceiling tile grids offer a versatile solution for enhancing the functionality and aesthetics of various spaces. Their numerous benefits, from improved acoustics to easier maintenance access, make them an attractive option for both commercial and residential environments. With a variety of design choices and installation options, suspended ceilings remain a popular choice for creating modern and efficient interior spaces. Whether you're looking to renovate an office or update your home, considering a suspended ceiling tile grid could be a smart investment that enhances your overall environment.

Installation Considerations

5. Finishing Touches After the hatch is installed, tape and mud the edges to blend it into the surrounding drywall, making it less noticeable.

No matter the setting, noise is bad for any environment. Whether in a restaurant, a cafe, an office or a grocery store, noise is the one factor that is bad for business.

gypsum vs pvc ceiling

When choosing and installing ceiling access hatches, it is crucial to consider building codes and safety regulations. Compliance with local and national standards is essential not only for legal reasons but also for ensuring occupant safety. Many metal access hatches are designed to meet these regulations, providing an additional layer of security and assurance to builders and owners alike.

Fibre ceilings are typically lightweight and easier to install compared to traditional ceiling materials. This ease of installation can lead to reduced labor costs and quicker project timelines. Furthermore, maintaining fiber ceilings can be less cumbersome as they are often designed to be washable and stain-resistant, ensuring that they maintain their appearance over time.

Specifications

Applications of Ceiling Grid Hanger Wire

Additionally, access panels are essential for ensuring the longevity of your home’s systems. Regular maintenance is crucial to prevent issues such as leaks, blockages, or electrical failures. An access panel allows you to perform spot checks and conduct routine maintenance without causing damage to your ceiling.

Fire Resistance and Safety

5. Insulation and Soundproofing Some plastic panels come with built-in insulation, which can help improve energy efficiency and provide soundproofing benefits. This feature is particularly beneficial in commercial buildings where noise reduction is a priority.

In the realm of modern construction and architecture, accessibility and safety are paramount considerations. One often overlooked yet crucial component of building design is the ceiling access panel equipped with a ladder. This essential fixture not only ensures easy access to often-neglected spaces, such as attics, ducts, and mechanical systems, but it also plays a vital role in maintaining the efficiency and safety of building operations.

2. Measure the Opening Once you've selected the location, measure the required opening for your access panel. A typical size is around 14 x 14 inches, but this might vary based on the intended use.

how to make a ceiling access panel