perforated metal panel railing

Latest articles

perforated metal panel railingGalvanized iron wire is widely used in construction, handicrafts, wire mesh, highway guardrail, product packaging and daily civilian and other fields.

...

perforated metal panel railing 【perforated metal panel railing】

Read Moreperforated metal panel railing

...

perforated metal panel railing 【perforated metal panel railing】

Read MoreDifferent hot dip galvanizing process is divided into two categories of annealing outside the line and annealing in the line, hot dip galvanizing is in the hot melt zinc liquid immersion plating, production speed, thick but uneven coating, the market allows Z low thickness of 45 microns, Z high can reach more than 300 microns. It is dark in color, consumes more zinc metal, forms infiltration layer with base metal, and has good corrosion resistance. Hot dip galvanizing can be maintained for decades in outdoor environment.

perforated metal panel railing...

perforated metal panel railing 【perforated metal panel railing】

Read More

perforated metal panel railingThe application range of positive and negative twisted barbed wire is also very wide. It is a good choice for purchasing barbed wire. So what are the advantages of positive and negative twisted barbed wire compared with other barbed wires? The following barbed wire factory will introduce the positive and negative twisted wire in detail. Three advantages of rope

...

perforated metal panel railing 【perforated metal panel railing】

Read MoreIf the requirements are higher, and it is humid place, it is recommended to use hot-dip galvanized barbed rope, although the price is higher, but the service life is longer, generally speaking, it is more cost-effective.

perforated metal panel railing...

perforated metal panel railing 【perforated metal panel railing】

Read MorePlastic spraying is often referred to as electrostatic powder spraying. It is the use of electrostatic emitter to make plastic powder charged, adsorbed on the surface of the iron plate, and then baked at 180~220℃ to melt the powder and adhere to the metal surface. Plastic spraying products are mostly used in indoor boxes, and the paint film appears flat or matte. Spray powder mainly acrylic powder, polyester powder and so on.

perforated metal panel railing...

perforated metal panel railing 【perforated metal panel railing】

Read Moreperforated metal panel railing

...

perforated metal panel railing 【perforated metal panel railing】

Read Moreperforated metal panel railing

...

perforated metal panel railing 【perforated metal panel railing】

Read Moreperforated metal panel railing

...

perforated metal panel railing 【perforated metal panel railing】

Read More

perforated metal panel railing

Post time: 28-01-23...

perforated metal panel railing 【perforated metal panel railing】

Read More

Popular articles

- Pay attention to safety in line collection and operation, others without the consent of the monitor, Ben have to get on the bus operation. The reels should be placed lightly, stacked firmly and neatly, not more than 5 reels. Direct contact with acid and alkali must be prohibited. When the acid fog exceeds the specified target of the state, measures should be taken to control it in time, otherwise production is not allowed.

With the improvement of living standards and the reduction of family size, keeping pets is becoming a way of life for many people. According to statistics, the number of pet dogs has reached more than 100 million, and the trend is increasing rapidly every year. Beijing alone had more than 900,000 licensed dogs in 2010, according to a survey, and the number of pet cats is also very large.

Latest articles

-

Galvanized iron wire has tolerance and elasticity, the amount of zinc can reach 300 g/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other fields.

-

-

During this process, each time the wire is pulled over, the surface hardens due to the high friction temperature. So basically every time you pull it you have to annealing it in the furnace. On the one hand, it is to reduce the surface hardness. On the other hand, during the process of wire pulling, only the surface is deformed, and the center is unchanged. So there’s a lot of stress inside. Therefore, it is necessary to rely on annealing to eliminate the internal stress, so that the wire becomes soft again to eliminate the stress before being drawn again.

-

-

-

Links

3. Versatility With the ability to perform a variety of stitches beyond just zigzag, including decorative and overlock stitches, industrial zigzag sewing machines can handle various sewing applications. This versatility makes them suitable for a wide range of projects, from clothing to home textiles.

industrial zigzag sewing machine for sale

Conclusion

2. Install the Double Needle Turn off your sewing machine for safety. Remove the current needle and insert the double needle into the needle clamp, ensuring that it is securely in place. The two needle points should hang down evenly to ensure proper stitching.

A double needle sewing machine is a specialized type of sewing machine that uses two needles and two threads simultaneously. This unique feature allows sewers to create two parallel rows of stitching, which can add depth and dimension to their work. Beyond simple straight stitching, this machine enables the creation of decoratively embroidered stitches, hems, and other details that can transform a basic garment into a tailored masterpiece.

3. Compatibility Heavy duty needles are designed to work with a range of sewing machines. However, it is always advisable to consult the sewing machine manual to ensure compatibility and avoid any potential issues.

Another common issue is skipped stitches, which can occur when the needle is dull or bent or when the machine is not properly calibrated. To address this issue, replace the needle with a new one that is suitable for heavy fabrics and ensure that it is inserted correctly. Additionally, check that the machine is properly adjusted and calibrated according to the manufacturer’s instructions.

(2) When the heavy material sewing machine is running, the steering of the upper wheel should be counterclockwise (viewed from the outside of the upper wheel).

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.

Conclusion

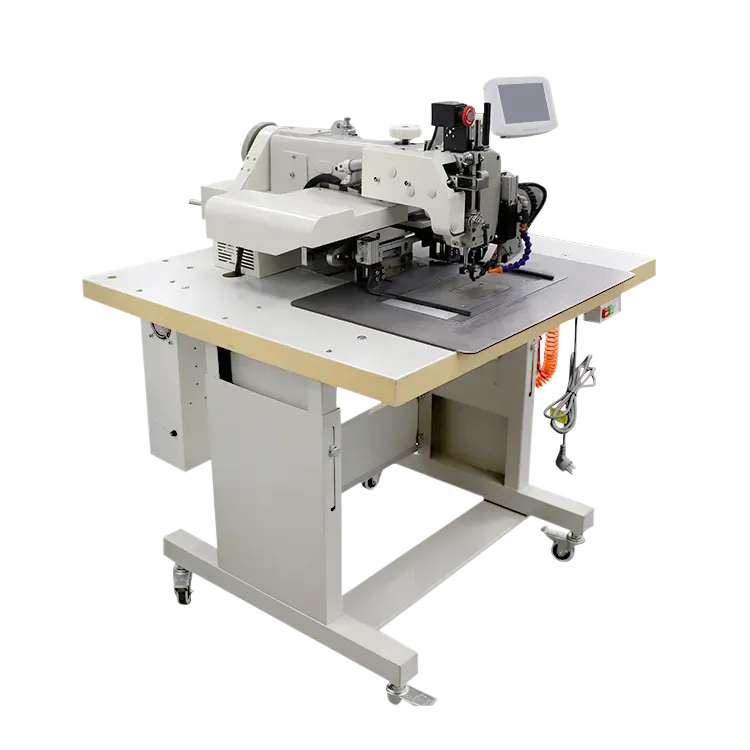

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Benefits of CNC Machine Sewing

Moreover, the accuracy of the stitching helps reduce wastage. By ensuring that designs are executed perfectly every time, manufacturers can minimize fabric loss, thus improving overall profitability. Additionally, the speed of production allows companies to respond promptly to market changes, fulfilling orders faster and enhancing customer satisfaction.

Handheld sewing machines are known for their portability and user-friendly design. They are perfect for quick fixes, on-the-go sewing needs, and small sewing tasks. Whether you need to hem pants, repair a torn seam, or work on craft projects, a handheld sewing machine can be your trusted companion.

The unique design of cylinder arm sewing machines offers several benefits that enhance both the quality and efficiency of sewing projects. One of the main advantages is their ability to provide consistent and precise stitching in hard-to-reach areas. This precision is crucial for producing professional-grade garments and accessories.Cylinder arm sewing machines are also known for their durability and power. They are built to handle heavy-duty materials and multiple layers of fabric, making them suitable for industrial use. This robustness ensures that the machine can perform consistently over time, even under demanding conditions.Another benefit is the versatility offered by these machines. They come with various attachments and accessories that expand their functionality, allowing users to tackle a wide range of sewing projects. From decorative stitching to heavy-duty construction, cylinder arm sewing machines are adaptable to different sewing needs.

Industrial Sewing Machines: The initial investment in these machines is high. Their specialized construction, durability, and high-performance capabilities come at a premium.

The number of stitches determines the sewing machine’s capacity. For instance, if it has multiple stitching options, then you can be more versatile as far as sewing is concerned. Other than this, the number of stitches per minute has an effect on how efficient the machine is.

If you're in the market for a heavy-duty leather sewing machine, you’re likely aware of the importance of having the right tools for your leatherworking projects. Whether you’re a seasoned professional or a hobbyist working on leather goods, a reliable sewing machine specifically designed for heavy materials can make a world of difference in the quality and efficiency of your work.

Investing in a commercial upholstery sewing machine is a crucial step for anyone serious about upholstery work. With the right machine, you can enhance your productivity, improve the quality of your work, and ultimately satisfy your customers. By understanding the features and options available, you can make an informed decision that will serve you well in your upholstery endeavors. Whether you’re a seasoned professional or just starting, the right sewing machine can make all the difference in achieving stunning upholstery results.

What is a Double Needle Long Arm Sewing Machine?

When looking for a carpet overlocking machine for sale, several factors should be taken into account to ensure that you make an informed decision

The Advantages of Automatic Needle Threader Sewing Machines

5. Versatility Lock stitch technology can be adapted to various sizes and types of jumbo bags, making it a versatile choice for different industries. Whether it’s for agricultural applications or heavy-duty construction materials, lock stitching can cater to specific needs.

How Does it Work?

Heavy duty sewing machines are changing how people create everything from stylish leather handbags to more rugged work clothes. Whether you’re a beginner who weaves the threads of your ideas or a craftsman who sews the best of tradition, these machines can meet a wide range of needs. Find out what a big part they play in industries like leather goods, denim manufacturing, custom furniture, industrial upholstery, and more, and decide if getting one is worth it.

Preparing Your Sewing Machine

The Heavy-Duty Mechanical Sewing Machine A Seamstress's Best Friend

The price of single needle sewing machines varies widely, typically ranging from $100 to over $1,000. Entry-level machines can start as low as $100 to $300, offering basic features suitable for beginners or casual sewists. Mid-range models usually fall between $400 and $800, providing a balance of functionality and durability for hobbyists and small business owners. High-end machines, often used by professionals, can exceed $1,000, boasting advanced capabilities and superior build quality.

Advantages of Using Hand-Powered Machines

woven sack sewing machine.

what does an overlocker do. The machine is designed to work with materials like jersey, spandex, and Lycra, which can be challenging to sew with a regular machine. The overlocker's differential feed system helps to prevent stretching or puckering of the fabric, resulting in smooth, even seams that move with the body.