aluminium perforated panel

Latest articles

aluminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read Morealuminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read More

aluminium perforated panel...

aluminium perforated panel 【aluminium perforated panel】

Read More

aluminium perforated panelAnnealing wire is widely used mainly because it has a good elasticity and flexibility, in the annealing process can be a good control of its hardness and softness, it is mainly made of iron wire, more commonly used in the construction industry tie wire use. So why annealing wire according to material properties processing?

...

aluminium perforated panel 【aluminium perforated panel】

Read Morealuminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read Morealuminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read Morealuminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read Morealuminium perforated panel

...

aluminium perforated panel 【aluminium perforated panel】

Read More

aluminium perforated panelThe welding core is the metal core of the electrode. In order to ensure the quality of the weld, there are strict regulations on the content of various metal elements in the weld core. In particular, there are strict restrictions on harmful impurities (such as sulfur and phosphorus), and the quality of the weld core metal should be better than that of the base metal. Arc welding cannot be carried out on a smooth rod without a coating. This is because the arc stability is very poor, splashing is very large, and the weld is not well formed. After long-term practice, it is gradually found that the performance of the electrode is greatly improved by coating the welding core with some mineral raw materials (i.e. electrode coating). (1) Ensure stable arc combustion, so that the welding process is normal. (2) Using the gas produced after the drug skin reaction, protect the arc and the molten pool, prevent the harmful gases in the air (such as nitrogen, oxygen, etc.) from invading the molten pool, such as these gases will cause cracks and pores in the welding material, so that the welding can not achieve the ideal effect. (3) After the drug skin is melted, slag is formed, which covers the weld surface to protect the weld metal, make the weld metal slowly cool, help the gas escape, prevent the generation of pores, and improve the structure and performance of the weld. (4) After melting, various metallurgical reactions will be carried out, such as deoxygenation, sulfur removal, phosphorus removal, etc., so as to improve weld quality and reduce alloying element burning loss.

...

aluminium perforated panel 【aluminium perforated panel】

Read More

aluminium perforated panelThe whole welding process of galvanized steel wire mesh does not need special technological methods, good weldability. However, in a few cases, the welding process will present difficulties: the converter steel produced by the old smelting method has high nitrogen content and high impurity content, resulting in high cold brittleness, added aging sensitivity, lower quality of welded joints, and poor weldability.

...

aluminium perforated panel 【aluminium perforated panel】

Read More

Popular articles

- Galvanized wire to galvanized uniform, a body is now its cross section, the second is the longitudinal uniformity. In the actual operation process, such as the jitter of steel wire, the surface of the pot scum and other reasons will cause galvanized wire surface galvanized layer accumulation, should try to solve the problem.

Large hexagonal mesh called stone cage net, is mainly used for mountain protection, hydraulic construction and so on. Small wire hexagonal mesh is used as a good material for breeding, will twist twist hexagonal mesh in the welded iron frame on the hexagonal mesh welding into chicken coop, pigeon cage, rabbit cage cage cage, hexagonal mesh is the best material for breeding with a net.

- At present, some manufacturers also use the process of sandblasting equipment for wire pretreatment, sandblasting process is carried out in the sandblasting room, but in the process of sandblasting, dust will permeate the whole sandblasting room, produce a lot of dust that is not easy to collect, and if the dust will be discharged at will.

Pet cage is generally made of high quality iron wire, low carbon steel wire, stainless steel wire welding, its characteristics are beautiful, light, folding, easy to store. Pet cage surface treatment is generally: cold galvanizing, hot galvanizing, spraying, dipping, chrome plating, nickel plating and other methods. Pet cage is mainly used for family breeding pets and protection. Tianfu metal products company specializes in the production of various specifications of pet cage such as pigeon cage, dog cage, bird cage, parrot cage and so on.

Latest articles

-

Galvanized barbed wire as a safety protection of the metal wall, the galvanized barbed wire device also need to be protected for a long time? And how to protect it? Maintenance and protection of galvanized barbed rope. First, we can start from two aspects. One is about the protection of galvanized barbed rope posts.

-

-

-

The fence effect of the barbed wire installation can be recognized by the majority of customers, its advantages are as follows: First of all, for some of the original protective device barbed wire because of the convenience of installation, the installation process is very simple, only need to fix the barbed wire column, and then gradually install the barbed wire according to the hook on the barbed wire column.

-

The advantages of hook net hook net raw material resolution of its use, used for road guardrail, sports stadium fence, etc., because the weaving characteristics of hook net can make the guardrail both beautiful and useful, have a good ability to hit, and can extend the service life, not easy to fade to prevent the effect of beautiful. And can also be used for family interior decoration, because its plasticity is very good so the use is also very much, is now many local are widely used.

-

The diameter of welded mesh wire for external walls is generally 2.2-ф4.0, and the mesh is generally 25-50.

Links

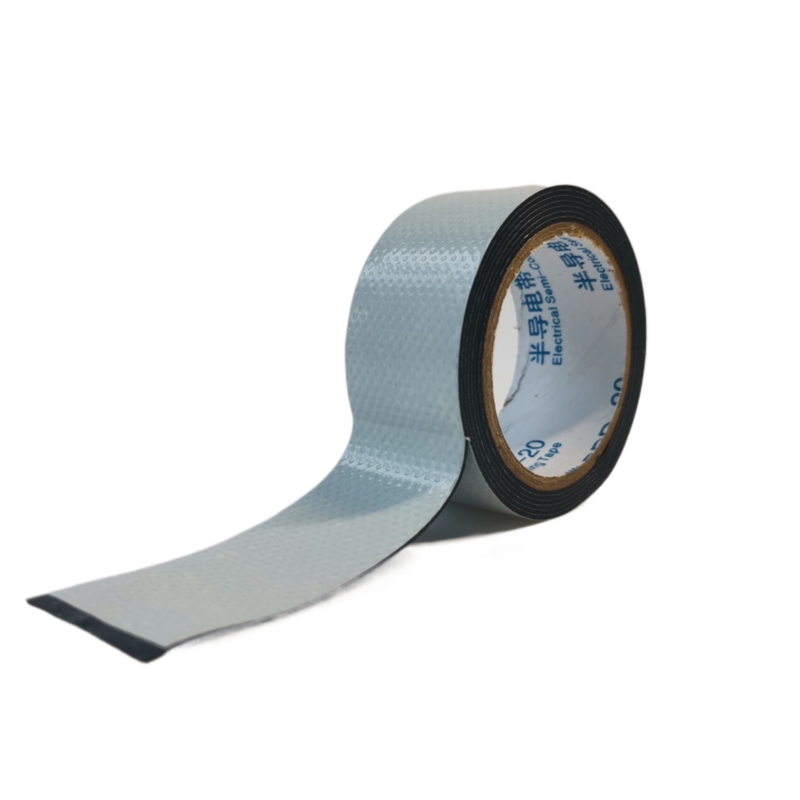

- Beyond standard applications, Gray Flex Seal Tape has found its way into numerous creative uses. From sealing cracks in boats and pools to repairing camping gear, it has proven its adaptability time and again. In emergency situations, it can even serve as a temporary fix for car repairs or to protect wounds from water exposure.

- In addition to its insulation properties, PVC insulation tape black is also highly flexible and easy to work with. It can be easily torn by hand, making it convenient for on-the-go applications. Its adhesive backing ensures a secure hold on the wires, allowing for a reliable and long-lasting connection.

Can you use Electrical Tape on Heat?

This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals

This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals flex tape 4 inch.

flex tape 4 inch.

In summary, temporary floor marking tape serves as an essential tool for enhancing safety, promoting organization, and improving efficiency in a wide range of environments. Its user-friendly nature, combined with its versatility, makes it an invaluable asset for businesses and individuals alike. By implementing this simple solution, organizations can foster a safer and more organized atmosphere that ultimately contributes to greater productivity and well-being. Whether in a bustling warehouse or a busy retail store, the impact of temporary floor marking tape is undeniable and worth considering for anyone looking to improve their operational effectiveness.

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications arc proof tape.

arc proof tape. waterproof butyl rubber tape. Easy to Use The tape is easy to apply, cut, and remove, making it a convenient solution for a wide range of sealing and bonding tasks.

waterproof butyl rubber tape. Easy to Use The tape is easy to apply, cut, and remove, making it a convenient solution for a wide range of sealing and bonding tasks.Elite Tape offers an extensive line of single coated film tapes with a variety of film backings and adhesive systems. Our polyester-silicone tapes are used for splicing silicone coated papers and high temperature masking applications. We offer these in different colors and different thickness’ depending on your application needs. We also offer polyester-acrylic tapes, polyimide-silicone, polyester-acrylic and polyethylene-rubber. All of these products can be procesed in long length machine rolls for continuous processing. We also offer these tapes die-cut in different designs and configurations. There are several applications requiring our single coated film tapes:

self bonding electrical tape. It provides a layer of protection against electrical shock and short circuits, making it a critical component in any electrical work.

self fusing rubber tape.

However, it’s important to note that the water resistance of Polyethylene Tape can vary depending on the specific formulation, thickness, and adhesive used. While it can withstand occasional exposure to water or damp environments, it may not be suitable for long-term immersion or continuous exposure to water.

One of the key advantages of using 130C linerless rubber splicing tape is its ability to provide a tight and secure seal. This makes it perfect for applications where a leak-proof bond is essential, such as in plumbing or automotive industries. The tape is also resistant to chemicals and oils, further enhancing its durability and reliability.

130c linerless rubber splicing tape

Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools

Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools flex tape gray. Simply clean the surface where you want to apply the tape, peel off the backing, and press it firmly into place. The tape will adhere securely to most surfaces, providing a strong and durable bond.

flex tape gray. Simply clean the surface where you want to apply the tape, peel off the backing, and press it firmly into place. The tape will adhere securely to most surfaces, providing a strong and durable bond.Now that we know everything there is to know about butyl tape, read through these last couple of points to help you purchase and apply this diverse adhesive tape.

Understanding 3M HT Insulation Tape A Versatile Solution for Various Applications

Corrosion resistance – the dielectric strength of electrical tape is a measure of its electrical strength as an insulator. Vinyl electrical tape is available with differing dielectric strength making it ideal to use for insulating high-voltage wires over extended periods of time. By comparison, PVC electrical tape can be used in similar situations but care should be taken that its dielectric strength is sufficient to insulate active wires.

Overall, self-fusing tape is a versatile and valuable tool that has a wide range of uses. Whether you're a DIY enthusiast looking for a quick and easy way to fix plumbing or electrical issues, or a professional tradesperson in need of a reliable sealant for various applications, self-fusing tape is a product worth considering. Its strong bonding properties, resistance to heat and water, and ease of use make it a must-have item for any toolbox.

In conclusion, floor marking tape is an important tool for creating safe, organized workspaces in a variety of environments. When considering the price of floor marking tape, be sure to prioritize quality, durability, and adhesive strength to ensure that you are getting the best value for your money. By carefully comparing prices and considering your specific needs, you can find the right floor marking tape at a price that fits your budget.

Electrical Tape comes in a variety of widths and lengths, so be sure to measure the area you need to cover before purchasing it.

The Versatile Uses of Yellow Insulation Tape

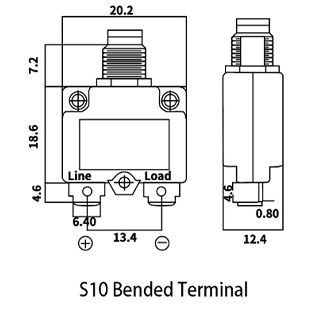

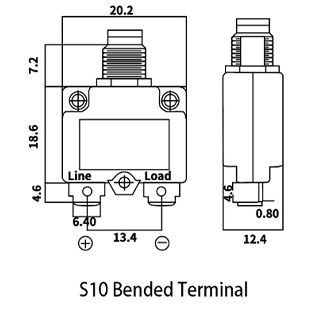

They are also responsible for protecting pumps against low and high voltage that can result from things such as short circuits and overloads.