expanded metal grid

Latest articles

expanded metal grid

...

expanded metal grid 【expanded metal grid】

Read MoreMost cattle nets are mechanically woven from high ductility and corrosion resistance of low carbon steel wire or PVC clad steel wire. Several common materials used in the manufacture of cattle nets are electrogalvanized wire, hot-dip galvanized wire, Galfan plated steel wire, 10 percent aluminum zinc alloy steel wire and the new selenium chromium plated steel wire.

expanded metal grid...

expanded metal grid 【expanded metal grid】

Read More

expanded metal grid

Post time: 02-08-22...

expanded metal grid 【expanded metal grid】

Read Moreexpanded metal grid

...

expanded metal grid 【expanded metal grid】

Read MoreThe management system of the rinsing water after the steel wire pickling should be regularly and regularly discharged after the rinsing water, and the rinsing water should be kept clean and low acid value as far as possible. The pH control is more appropriate. The concentration of plating aid should not be too high. Hot plating wire must be added ammonium chloride and zinc chloride according to the data of laboratory analysis, and the specific gravity of the composite solution is controlled in the range of 50~80g/L. The addition of ammonium chloride or zinc chloride raw materials without the results of laboratory analysis shall be subject to criticism and education, and economic treatment if necessary.

expanded metal grid...

expanded metal grid 【expanded metal grid】

Read Moreexpanded metal grid

...

expanded metal grid 【expanded metal grid】

Read Moreexpanded metal grid

...

expanded metal grid 【expanded metal grid】

Read More

expanded metal gridWe often choose what kind of barbed rope instead of the type of barbed rope. In fact, the type of barbed rope is as important as the type of barbed rope. Let’s talk about the difference between 304 and 201 of the barbed wire rolling cage.

...

expanded metal grid 【expanded metal grid】

Read More

expanded metal grid4. Keep the rinsing water clean after wire pickling

...

expanded metal grid 【expanded metal grid】

Read More

expanded metal gridThe impregnated hexagonal wire mesh will lose its original characteristics after corrosion, and will change in shape, color and mechanical properties, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment than dry environment easy corrosion, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated hexagonal wire mesh, prolong the service life of products.

...

expanded metal grid 【expanded metal grid】

Read More

Popular articles

Usually, there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment is easier to rust than dry environment, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the customized corrosion of hexagonal guardrail and extend the service life of the product.

- Generally speaking, in dry main gas and indoor use, the thickness of galvanized coating is only 6-12μm, but under poor environmental conditions, the thickness of galvanized coating is 20μm, can reach 50μm. Therefore, environmental factors should be considered when choosing the thickness of galvanized layer. Galvanized layer after passivation treatment, can naturally form a layer of bright, beautiful color passivation film, can obviously improve its protective function, decorative.

Post time: 17-05-23

Latest articles

-

5, the concentration of plating aid can not be too high, which is a factor that can not be ignored to reduce zinc consumption. The concentration of plating aid should not be too high. The galvanized line must be added with ammonium chloride and zinc chloride according to the data of laboratory analysis, and the specific gravity of the composite solution should be controlled within the range of 50~80g/L. If ammonium chloride or zinc chloride is arbitrarily added without the results of laboratory analysis, it should be criticized and educated, and economic treatment should be given if necessary.

-

-

The management system of the rinsing water after the steel wire pickling should be regularly and regularly discharged after the rinsing water, and the rinsing water should be kept clean and low acid value as far as possible. The pH control is more appropriate. The concentration of plating aid should not be too high. Hot plating wire must be added ammonium chloride and zinc chloride according to the data of laboratory analysis, and the specific gravity of the composite solution is controlled in the range of 50~80g/L. The addition of ammonium chloride or zinc chloride raw materials without the results of laboratory analysis shall be subject to criticism and education, and economic treatment if necessary.

-

-

Post time: 18-10-22 -

2. The positive and negative twisting barbed wire is cost-effective

Links

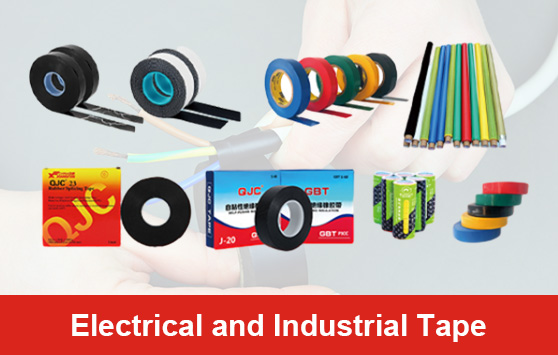

- In an increasingly safety-conscious world, the role of fire-resistant adhesive tape cannot be overstated. This specialized type of tape, designed to withstand high temperatures and resist ignition, plays a pivotal part in various industries, from construction to electronics, automotive, and aerospace.

The tape is also known as ‘F4 tape’, ‘tommy’, ‘rescue’, ‘magic tape’ and ‘fix-it tape’.

- The tape's adhesive properties ensure a secure hold, keeping the wires in place and reducing the risk of short circuits or disconnections. It also aids in reducing electromagnetic interference, which could disrupt the vehicle's electronic systems. Moreover, the color-coded and labeled tapes make it easier for technicians during installation and maintenance, enhancing efficiency and minimizing errors.

- Vulcanization, a process first discovered by Charles Goodyear in the 19th century, involves the chemical modification of rubber through heat and pressure, resulting in a more durable and resilient material. This process enhances the natural properties of rubber, making it resistant to heat, cold, ozone, and aging, thereby increasing its longevity and performance. When applied to tape, this process transforms it into a high-strength, waterproof, and heat-resistant sealing solution - the vulcanizing tape.

- In conclusion, car wiring loom tape is a crucial component for maintaining the electrical system in any vehicle. It provides protection against shorts and fires, helps to secure and organize the wiring harnesses, and improves the overall appearance of the engine bay. By investing in a high-quality tape and properly wrapping the wiring loom, you can ensure the reliability and longevity of your vehicle's electrical system.

- Beyond energy conservation, door seals with rubber strips also contribute to noise reduction. In urban environments or homes near busy roads, excessive noise can be intrusive and disturbing. The rubber strips act as a buffer, muffling sounds that try to penetrate through door gaps, thereby maintaining a quieter and more peaceful indoor environment. This is particularly beneficial for bedrooms and studies where a serene atmosphere is crucial for rest and productivity.

- 2. **Stretching** To ensure accurate measurements, stretch the tape tightly along the floor or wall.

- Thermal Protection

- At first glance, flex tape's robust nature is evident. The 4-inch width provides an expansive canvas for creativity and functionality. It adheres firmly to numerous surfaces, creating watertight seals around pipes, repairing tears in fabrics, or forming sturdy, temporary bonds between materials that need to be held together. This adaptability makes it an indispensable item for both everyday chores and emergency fixes.

Useful applications

Although they may seem like simple devices, control boxes pack numerous components in that centralized box. These components include;

- The primary function of this tape is insulation. It provides a reliable barrier against electrical current leakage, protecting both the wiring and the people working on it. When used properly, wrapping black electrical insulation tape around live wires or terminals can help prevent short circuits and reduce the risk of electrical shock. Additionally, the tape’s insulative properties are beneficial in shielding sensitive electronic components from electromagnetic interference.

- During emergencies, temporary floor markings can direct evacuation routes, pointing towards exits and safe zones. They can also indicate fire extinguishers, first aid kits, and other safety equipment, ensuring swift response in crisis situations. In healthcare facilities during the COVID-19 pandemic, this tape has been instrumental in implementing social distancing measures, marking out appropriate distances for queues and seating arrangements.

In conclusion, fire-resistant electrical tape is a critical component for anyone involved in electrical work, whether in an industrial or residential context. Its unique properties make it an effective solution for enhancing electrical safety and preventing fire hazards. As electrical systems become increasingly complex, the importance of using specialized materials such as fire-resistant electrical tape cannot be overstated. Prioritizing safety should be a guiding principle for all electrical projects, making fire-resistant tape an essential tool in every toolkit.

- Furthermore, rubber seal strips are used in a variety of other applications, such as in appliances, electronics, and industrial machinery. These strips help to provide protection against moisture and dust, as well as to dampen vibrations and reduce noise levels. In the automotive industry, rubber seal strips are used to seal body panels, windows, and sunroofs, providing a watertight and airtight seal.

- Output Control:After processing the input data, your control box subsequently reaches out to your connected devices. This could be a conveyor system or a motor. It conveys the required action thereby initiating the needed countermeasures. For instance, if the linked system is a packaging machine, the control box may send a signal commanding the conveyor system to up its speed.

- The functionality of the rubber strip for door seal is multifaceted. Primarily, it serves as a barrier against drafts and weather elements, preventing cold air from seeping into your home during winter months and keeping cool air inside during the summer. This not only adds to the comfort of your indoor environment but also contributes significantly to energy conservation efforts. By reducing the need for heating or air conditioning, the rubber strip can lead to notable reductions in energy bills.

Conclusion

In addition to providing protection, car harness tape also helps to organize and secure the wiring harnesses in your vehicle. By neatly wrapping the tape around the harnesses, you can prevent them from getting tangled or damaged during routine maintenance or repairs.

Furthermore, safety floor tape can be used to create warning signs or instructions directly on the floor

. This is particularly useful in environments where traditional signage may not be practical or visible, such as on busy factory floors or in dimly lit warehouses. By using floor tape to communicate important information, employers can ensure that safety protocols are clearly understood and followed by all employees.3. Durability and Longevity Fireproof gasket tape is engineered to stand the test of time. It is resistant to degradation caused by UV light, moisture, and extreme temperatures, ensuring a long-lasting seal that minimizes the need for frequent replacements. This durability is particularly beneficial in harsh industrial environments, where traditional tapes may fail prematurely.

Self-adhesive insulation tape has also found its way into the crafting world. Artists and DIY enthusiasts utilize it to create unique designs, patterns, and textures in their projects. Its availability in different colors and widths encourages creativity, allowing individuals to experiment with various artistic expressions. Whether for scrapbooking, home decor, or personalized gifts, this tape adds both function and flair to creative endeavors.

Sustainability is another crucial consideration in today’s manufacturing landscape. 3M is committed to producing solutions that not only meet industry standards but also minimize environmental impact. The company employs advanced manufacturing processes and materials that adhere to strict regulatory guidelines, ensuring that users can feel confident about their ecological footprint when using 3M HT Insulation Tape.

In a typical tape splice, you’ll tug and pull out the tape, stretching it to just before the breaking point. The tape’s width narrows to about 1/3rd of its original size. The tape’s length increases; your hand travels very quickly up to 20” away from where you started. Quite often you’ll be wrapping in a tight location making this even more difficult. Proper taping techniques are critical to realizing the many performance benefits of rubber tape.

In warehouses and factories, heavy duty floor tape plays a vital role in creating organized and safe work environments

. It can be used to mark aisles, designate parking spots for machinery, and indicate where equipment or materials should be stored. By clearly marking these areas, accidents and confusion can be minimized, leading to increased efficiency and productivity.heavy duty floor tape

PVC insulation tape is ideal for low voltage applications. It has various uses which include: insulation, sealing, maintenance, protection, fixing and colour-coding. Our PVC Insulation Tape is available in an assortment of colours to facilitate colour-coding for safety and identification purposes.

high voltage insulation tape. This is particularly useful in industrial settings where chemicals are commonly used in processing or manufacturing operations.

high voltage insulation tape. This is particularly useful in industrial settings where chemicals are commonly used in processing or manufacturing operations.