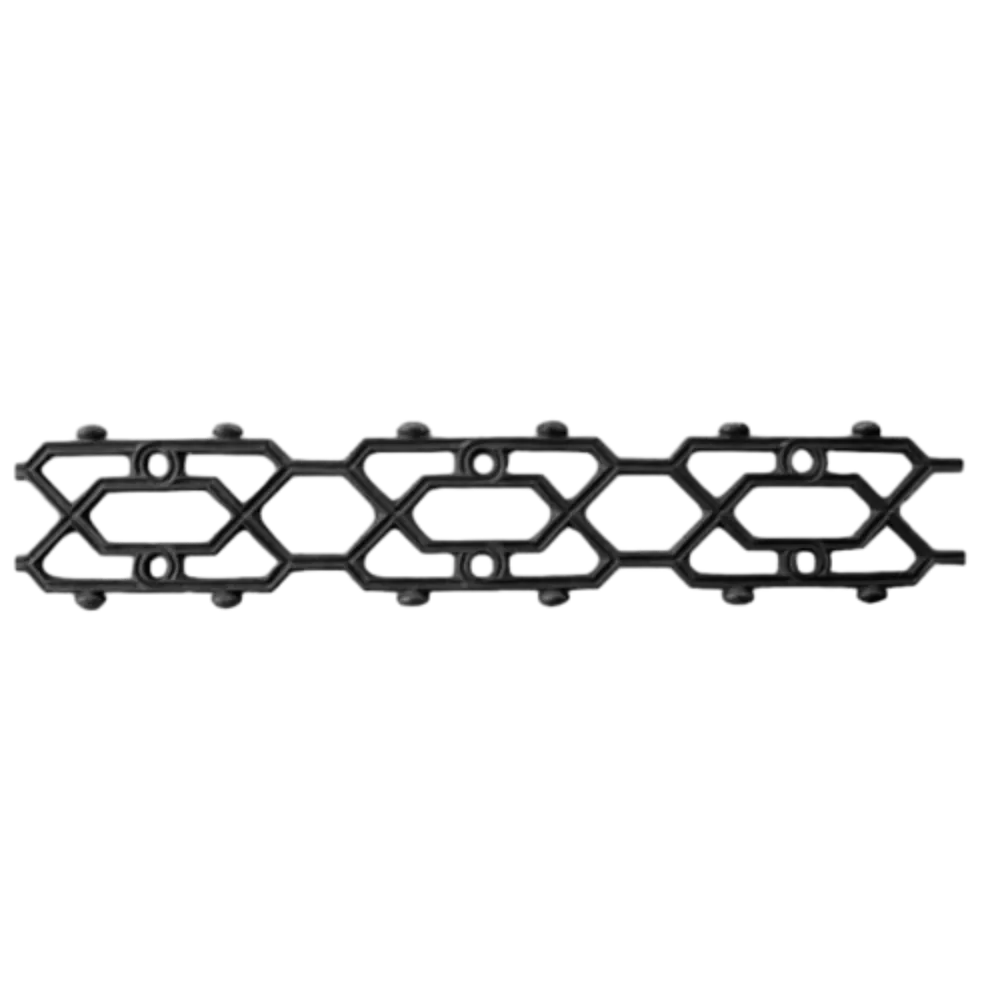

6 ft welded wire fence panels

Latest articles

Hot dip galvanizing is the plating of zinc layer on the surface of Angle steel, channel steel and other metals to achieve the appearance of convenience and rust prevention of metal. Hot-dip zinc processing plants use zinc tin solution to prevent corrosion on the workpiece. This new technology can extend the corrosion time by up to five times, which is usually used in outdoor construction. Because the principle of action is not the same, so the role of the workpiece is not the same. The appearance of hot dip zinc plant is only to expand the scope of action.

6 ft welded wire fence panels...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More6 ft welded wire fence panels

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More6 ft welded wire fence panels

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

6 ft welded wire fence panels

Post time: 08-08-22...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More6 ft welded wire fence panels

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

6 ft welded wire fence panelsIn order to pack and bind galvanized wire in the surface of the sedimentary layer to local removal of surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is formed when soap and surfactants such as saponified fats are brought into the tank. Moderate rates of foam formation may be harmless. Small, homogeneous particles of large denier present in the bath can stabilize the foam layer. Use activated carbon mat to remove surface active substance. Or through filtration to make the foam is not too stable, which are effective measures; Other measures should also be taken to reduce the amount of surfactant introduced. The electroplating speed can be obviously reduced by the addition of organic matter. Although chemical formulations facilitate high deposition rates, the deposition of organic matter does not meet the requirements of coating thickness, so activated carbon can be used to treat the bath.

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More6 ft welded wire fence panels

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

6 ft welded wire fence panelsLarge rolls of galvanized silk play a very important role in our life. Made of low carbon steel rod processing, after drawing forming, pickling rust removal, high temperature annealing, hot dip galvanized. Cooling and other process processes. Galvanized wire is divided into hot galvanized wire and cold galvanized wire (electric galvanized wire). Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance.

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

6 ft welded wire fence panels

Post time: 15-06-22...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

6 ft welded wire fence panels3. Acid activation acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts, without excessive corrosion on the matrix.

...

6 ft welded wire fence panels 【6 ft welded wire fence panels】

Read More

Popular articles

- Alias: gabion mesh, heavy hexagonal mesh, ecological mesh, wire mesh, etc.

Enclosure to calculate the use of barbed rope, so as to reasonably plan to purchase the amount of barbed rope to facilitate construction

The characteristics of galvanized hexagonal net: easy to use; Save transportation costs. It can be shrunk into small rolls and involved in moisture-proof paper packaging, taking up little space. Coating thickness uniformity, stronger corrosion resistance; The construction is simple and does not require special technology; Strong resistance to natural damage and corrosion resistance and adverse weather effects; Can withstand a large range of deformation, and still not collapse. It has the function of fixed heat preservation and insulation.

In the use of time do not need to carry out daily maintenance and maintenance, not only can save a lot of time, but also can reduce the cost, but also has good stability, strong corrosion resistance, greatly prolong the service life. According to the different process is divided into different kinds, can be selected according to their own needs, has good flexibility and elasticity. The main role of annealing wire is to control its degree of hardness and softness. When making annealing wire, it is made of steel wire.

Post time: 21-03-23

Latest articles

Links

- In conclusion, adjusting the rollers on a sliding screen door is a simple DIY task that can save you the hassle and cost of professional repair. Remember, prevention is key; regular cleaning and lubrication can help prolong the life of your door's rollers and maintain its functionality. With a little effort and attention, your sliding screen door will continue to serve its purpose efficiently.

- On the aesthetic front, aluminium profile windows provide a clean and contemporary look that complements various architectural styles. The frames are available in multiple finishes, including matte, glossy, and metallic shades, along with a plethora of colors that can either blend subtly with or make a bold statement against building facades. Additionally, the frames' thinness allows for more glass area, which further emphasizes the view and natural lighting.

- Furthermore, stainless steel front door pull handles offer excellent value for money. While they might have a higher initial cost compared to some other materials, their durability means they rarely need replacement. Over time, this can result in significant savings, especially when considering the cost of periodic replacements and repairs associated with less durable options.

- Secondly, aluminium is a lightweight material, which makes it easy to handle and install. This is particularly beneficial in remote or hard-to-reach areas where access to tools and equipment may be limited.

They are used for structural purposes in different construction, architectural and industrial settings.

- In conclusion, cast iron corner castings are essential components that contribute to the strength, durability, and stability of structures and equipment in various industries. With their impressive strength-to-weight ratio, durability, ease of installation, and versatility, cast iron corner castings are a reliable choice for applications that require robust support and reinforcement. By using cast iron corner castings, engineers, builders, and manufacturers can ensure the longevity and performance of their projects, ultimately leading to safer and more durable structures for years to come.

- Cast iron panels are a popular choice for both interior and exterior design due to their durability, versatility, and unique aesthetic appeal. These panels are made of a type of iron that is cast in a mold and then finished to create intricate designs and patterns.

Key Benefits

For those of us who want sheds that are very small, such as five square feet or less, then it will not really be necessary to add any sort of roof onto it. This is because you will only need to spend money on the framing itself and this is something that you can do yourself. Therefore, if you already have a strong foundation such as concrete then it will make sense to install a concrete wall as the main part of your shed.

3. Inspect for Wear and Tear Regularly check the rollers for signs of wear, cracking, or damage. Replace any broken components promptly to avoid further damage.

In contemporary design, okrasná liatina continues to play a vital role. Designers increasingly incorporate this timeless material into modern aesthetics, blending traditional craftsmanship with innovative techniques. Furniture pieces, light fixtures, and home decor items often feature cast iron, where its classic elegance meets modern minimalism. The recycling of old cast iron further emphasizes sustainability, providing new life to a material that has a rich history.

Types of Aluminum Profiles For Doors and Windows

Easy Maintenance

Other types of opening windows

The Importance of Choosing the Right Wrought Iron Supplier

handle for metal door. Handles for metal doors are often equipped with features such as key locks or electronic access control systems to prevent unauthorized entry. These security features help to protect the contents of a building or facility and provide peace of mind to property owners and occupants.

Steel door pull handles require minimal maintenance compared to other materials. A simple wipe down with a damp cloth is usually sufficient to keep them looking new. Unlike wood, which may need periodic refinishing, or plastic, which can discolor over time, steel handles can withstand the test of time with little upkeep. Their resistance to rust and tarnishing, particularly when finished properly, ensures longevity and an appealing appearance.