cyclone fence repair

Latest articles

Galvanized iron wire has excellent endurance and elasticity, zinc content can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, silk screen preparation, highway guardrail, commodity packaging and ordinary civilian categories.

cyclone fence repair...

cyclone fence repair 【cyclone fence repair】

Read Morecyclone fence repair

...

cyclone fence repair 【cyclone fence repair】

Read More

cyclone fence repairOne is the frame isolation net, guardrail net with frame, frame using material cold plate belt welded into the square tube, usually 2*3 thickness 1.2 thick, the middle for low carbon steel wire welding mesh, wire diameter can choose another welding aperture can also choose, for example, customers want good quality long service time, you can choose thick wire diameter, small welding aperture, Such mesh is not only high quality, but also long service life, customized mesh and frame after welding, surface treatment to reach the customer needs of goods.

...

cyclone fence repair 【cyclone fence repair】

Read More

cyclone fence repairSome customers do not understand the scope of application of different styles of barbed rope, there is a great difference.

...

cyclone fence repair 【cyclone fence repair】

Read More

cyclone fence repairNo matter how old dogs are, they seem to love to touch noses with people and other animals. In fact, dogs touch noses as a way of socializing, just like humans shake hands and hug when they meet. But dogs don’t nuzzle every human or every animal. They pick and choose who to nuzzle. If they don’t like you, or don’t know you at all, they won’t touch your nose. However, adult dogs will touch almost every puppy’s nose, and they will not only touch the puppy’s nose, but also smell the puppy’s body.

...

cyclone fence repair 【cyclone fence repair】

Read More

cyclone fence repair

Post time: 26-07-22...

cyclone fence repair 【cyclone fence repair】

Read MoreThere are many kinds of zinc plating solution, which can be divided into plating solution and no plating solution according to its properties. The galvanized liquid has good dispersion and covering property, the coating crystal is smooth and fine, the operation is simple, the application range is wide, and the long-term use is in the production. However, due to the toxic substances contained in the plating solution, the gas escaping from the plating process has great harm to the health of workers, and the waste water must be treated strictly before discharge.

cyclone fence repair...

cyclone fence repair 【cyclone fence repair】

Read Morecyclone fence repair

...

cyclone fence repair 【cyclone fence repair】

Read More

cyclone fence repair

Post time: 17-05-23...

cyclone fence repair 【cyclone fence repair】

Read Morecyclone fence repair

...

cyclone fence repair 【cyclone fence repair】

Read More

Popular articles

Broken wire is the iron bright wire, fire wire, galvanized wire, plastic coated wire, paint wire and other metal wire, wire factory according to customer requirements for straightening after sizing cut, has the characteristics of easy transportation, easy to use, widely used in the construction industry, handicrafts, daily civilian and other fields. No limit on length, packing as required. Annealing wire also known as black oiled wire, black annealing wire, fire wire, black iron wire. Compared with cold drawing, black annealed wire is more economical as raw material for nails.

For the specification of galvanized wire, the galvanized wire produced by our factory can range from No.8 to No.22, which refers to the BWG standard, that is, from about 4mm to 0.7mm, which can basically cover the type required by the customer. As for the raw material of galvanized wire, normally, we use Q195 mild steel, and some factories will also use SAE1006 or SAE1008. The following is the zinc coating, for galvanized wire, this is very important, the general zinc coating is about 50g/m2 to 80g/m2, some customers need high zinc galvanized wire, zinc coating can reach 200g/m2 to 360g/m2. The tensile strength of galvanized wire is usually 350n/m2 to 800n/m2. Then there is the packaging specification of galvanized wire. The specifications of small rolls of galvanized wire are 50kg/ roll, 100kg/ roll and 200kg/ roll. Of course, there are large rolls of galvanized wire, the weight can reach 300kg/ roll or 800kg/ roll.

Post time: 18-08-22- Packaging: electric welding net general packaging for moisture-proof paper (color is mostly gray white, yellow, plus trademarks, certificates, etc.), some like 0.3-0.6mm domestic sales of small wire diameter electric welding net, because the wire is relatively soft, coupled with small volume, customers often require packing processing, in order to prevent shipment caused by damage. The wire of electric welding mesh has straight, also has a wavy bend (also known as the Dutch net)

Post time: 11-05-23

Latest articles

-

-

Large hexagonal mesh called stone cage net, is mainly used for mountain protection, hydraulic construction and so on. Small wire hexagonal mesh is used as a good material for breeding, will twist twist hexagonal mesh in the welded iron frame on the hexagonal mesh welding into chicken coop, pigeon cage, rabbit cage cage cage, hexagonal mesh is the best material for breeding with a net.

-

Now more and more people are buying the barbed rope, but there are often a lot of people do not know the specifications of the blade barbed rope when they buy, here is to introduce the specific characteristics of the blade barbed rope.

-

-

Cold galvanizing (galvanizing) is in the plating tank after the current unidirectional, so that the zinc gradually plated on the metal surface, slow production speed, uniform coating, thin thickness, usually as long as 3-15g, bright appearance, poor corrosion resistance, usually a few months will rust. Compared with hot dip galvanizing, the production cost of electric galvanizing is lower.

-

Links

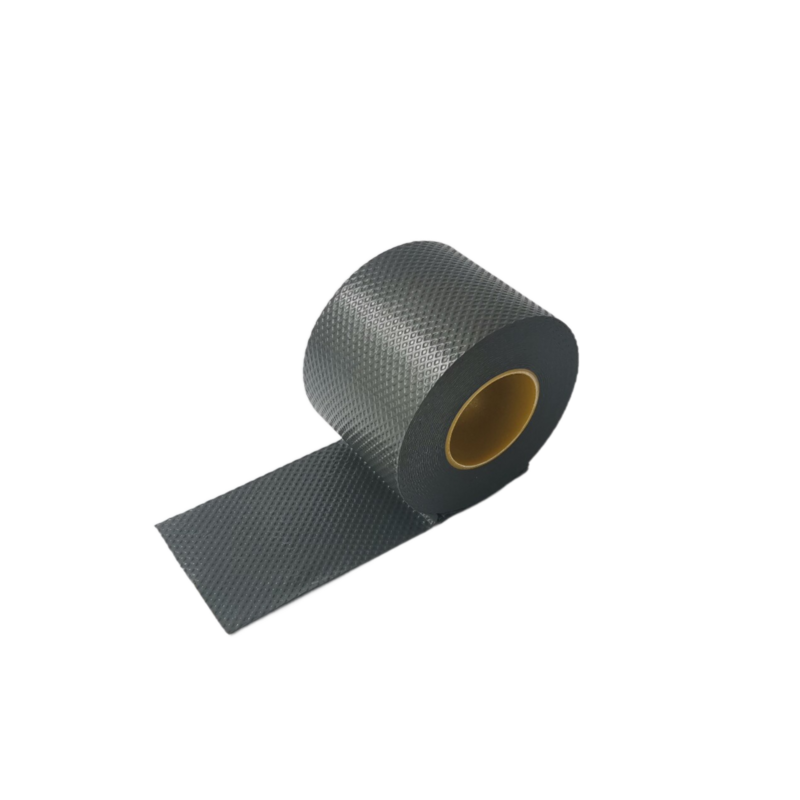

- Strong Adhesion: Rubber adhesives provide strong initial adhesion to a wide range of surfaces. They form a reliable bond quickly, ensuring secure attachment of the tape to the substrate. This is particularly beneficial in applications where immediate adhesion and holding power are crucial.

- 5. Inspect the installation After the compound has dried, inspect the installation to make sure there are no gaps or areas where the tape has come loose. If necessary, reapply the tape and compound.

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues