bulk woven wire fence

Latest articles

bulk woven wire fence

...

bulk woven wire fence 【bulk woven wire fence】

Read More

bulk woven wire fenceWe must have a certain understanding of the hexagonal network, we are the beautiful shape of the hexagonal network, more than the appearance of the hexagonal network is very beautiful, in fact, the practical value of survival is very high. To introduce the relevant information should be very clearly know the highway guardrail net, hexagonal wire netting in all kinds of fence netting, in the value of the high-speed on the road more MaoJian, it not only be used in all kinds of road, in a sports ball games venue and try our best to take care of landslides, also has reached very matter effectiveness.

...

bulk woven wire fence 【bulk woven wire fence】

Read MoreBecause the coating obtained is thicker, hot-dip galvanizing has very good protective function than electric galvanizing, so it is an important maintenance coating for iron and steel parts in strict working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, electric power transportation, shipbuilding and other occupations. In the field of agriculture, such as pesticide irrigation, greenhouse and construction industry such as water and gas transportation, wire casing, scaffolding, Bridges, highway guardrail and other aspects, it has been widely used in these years.

bulk woven wire fence...

bulk woven wire fence 【bulk woven wire fence】

Read More2, line diameter, mesh spacing (refers to the edge of the twist to the opposite side of the distance).

bulk woven wire fence...

bulk woven wire fence 【bulk woven wire fence】

Read MoreApplication scope of hot wire: Because the coating is thicker, hot galvanized has better protective performance than electric galvanized, so it is an important protective coating for steel parts used in harsh working conditions. Hot galvanized products in chemical equipment, petroleum processing, ocean exploration, metal structure, power transmission, shipbuilding and other industries have a wide range of applications, in the agricultural field such as pesticide irrigation, greenhouse and construction such as water and gas transmission, wire casing, scaffolding, bridge, highway guardrail and other aspects, in recent years has been widely used.

bulk woven wire fence...

bulk woven wire fence 【bulk woven wire fence】

Read Morebulk woven wire fence

...

bulk woven wire fence 【bulk woven wire fence】

Read More

bulk woven wire fence

Post time: 17-11-22...

bulk woven wire fence 【bulk woven wire fence】

Read Morebulk woven wire fence

...

bulk woven wire fence 【bulk woven wire fence】

Read More

bulk woven wire fenceThe impregnated hexagonal wire mesh will lose its original characteristics after corrosion, and will change in shape, color and mechanical properties, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment than dry environment easy corrosion, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated hexagonal wire mesh, prolong the service life of products.

...

bulk woven wire fence 【bulk woven wire fence】

Read Morebulk woven wire fence

...

bulk woven wire fence 【bulk woven wire fence】

Read More

Popular articles

Blade rope in the world has been widely used in the military, prison, government agencies, banks; Living community wall, private residence, villa wall, doors and Windows, highway, railway guardrail and border line and other protection security.

- The mesh size of the wire mesh specification, as well as the diameter and thickness requirements, are limited to the amount of steel and galvanized per square meter. Mainly in order to consider the corrosion resistance, prolong the service life, and in the use of the process of safety.

Latest articles

-

-

4. Substrate material: The substrate material of electrogalvanized wire also has a certain impact on its corrosion resistance. The substrate of different materials has different chemical properties and electrochemical activities, and the corrosion performance is different under different environmental conditions, and the compatibility with zinc layer will also have a certain impact on the corrosion performance.

-

-

-

-

Links

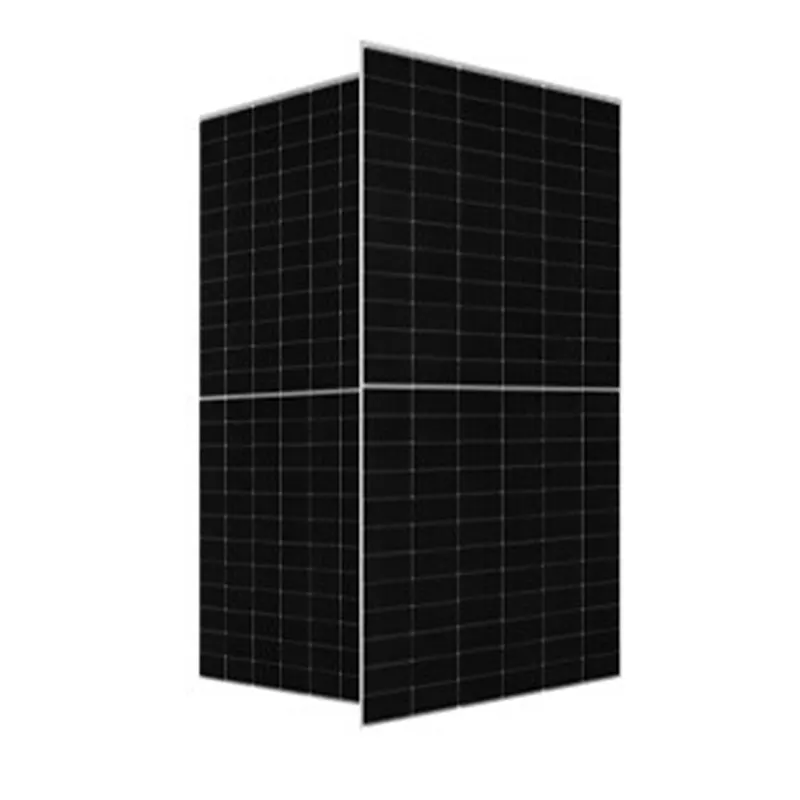

The History of PV Cells

The advancement in solar panel efficiency, particularly the emergence of 40% 20-watt panels, implies a bright future for renewable energy technology. As efficiency improves and manufacturing processes evolve, the cost per watt is expected to decrease, making solar energy more accessible. These innovations will likely encourage individuals and businesses to invest in solar energy, dramatically increasing its footprint in power generation.

- - Energy Independence With a solar energy system in place, users can rely less on the grid, providing a buffer against rising energy prices and potential power outages.

Solar panels are primarily classified by their physical dimensions and the amount of electricity they can generate. In general, the average size of a residential solar panel is about 65 inches by 39 inches, which is roughly 1.6 square meters in area. However, there are larger panels available for commercial uses, and these can range from 80 to over 100 inches long. Solar panels are typically measured in watts, and their output can vary significantly based on size.