4x8 perforated metal sheet

Latest articles

4x8 perforated metal sheetPet cage is generally made of high quality iron wire, low carbon steel wire, stainless steel wire welding, its characteristics are beautiful, light, folding, easy to store. Pet cage surface treatment is generally: cold galvanizing, hot galvanizing, spraying, dipping, chrome plating, nickel plating and other methods. Pet cage is mainly used for family breeding pets and protection. Tianfu metal products company specializes in the production of various specifications of pet cage such as pigeon cage, dog cage, bird cage, parrot cage and so on.

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More

4x8 perforated metal sheetThe material of steel structure will affect the organization and thickness of hot dip galvanized film. For example, high tension steel containing silicon, carbon content is high, easy to react with molten zinc quickly, the result of excessive growth of alloying, will cause a grayish black appearance, but does not affect its corrosion resistance. Or heat treated steel, if its tensile strength exceeds 90kg/mm2, after hot dip operation, easy to reduce its strength, etc.

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read MoreSome herdsmen avoid the intrusion of wild animals and other people’s livestock and from time to time to increase the grassland grassland stainless steel barbed rope fence net, so that the grassland grassland stainless steel barbed rope fence net has become a barrier to all kinds of wild animals. It is in herders’ interests to increase the number of their livestock, but consciously raising barbed ropes not only directly frightens and harms wildlife, but also cuts them off from food and migration.

4x8 perforated metal sheet...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More

4x8 perforated metal sheetPet cages can be used for indoor and outdoor pet houses. The dog cage is equipped with a fixed food basin and a drinking device, and the rubber pad of the pet cage with a bayonet on the four sides can be assembled. Can be splicing according to the size of the cage, shear, disassembly convenient, easy to clean, can solve the puppy in the ordinary cage pinched foot problem, prevent the puppy in the development of adverse reactions. The bulkhead of the pet cage is breathable and comfortable, which can be used as a heat shield for pets in summer. A puppy with small feet, not a foot, not a pinch.

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More

4x8 perforated metal sheet...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More4x8 perforated metal sheet

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read MoreZinc pot workers should be determined to do duty and responsibility. Do not leave the post without leave, always observe the change of hot plating wire galvanized layer, and according to the analysis results, master the asbestos block gap friction, how long it takes to press, replace the pressing face; Adjust the working face; Until all four sides of the asbestos block are used up, maintenance workers will continue to use the block after repair when necessary to reduce the consumption of asbestos block.

4x8 perforated metal sheet...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More4x8 perforated metal sheet

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More

4x8 perforated metal sheet3, with oil cloth (oil used cloth), carefully from inside to outside, including each cage wire repeatedly grinding many times. The front of the bird cage, the door flowers, where vision is often in place, are repeatedly rubbed in order to improve the surface finish, equivalent to “grinding”. Note: door flowers, arhat lines and other structures are delicate and fragile, do not break. This process, which requires time and patience, care, is also a process of observing and appreciating the cage. Use new cloth again, according to the above process, wipe again and again. This process is equivalent to polishing. For important parts, you can use a little force, the speed can be a little faster (do not use force). Be careful to fold the cloth neatly, otherwise marks will easily form. When this process is complete, the surface finish is significantly improved.

...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read MoreBridge bridge reinforcement is durable in poor function and aging, etc., through the wire mesh reinforcement, can prolong the service life of the bridge, avoiding the phenomenon of bridge cracks, subsidence and so on, wire mesh can play an obvious effect of crack in bridge reinforcement engineering, engineering construction speed, to enhance the crack resistance of concrete function, better economic benefit.

4x8 perforated metal sheet...

4x8 perforated metal sheet 【4x8 perforated metal sheet】

Read More

Popular articles

Most of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

Post time: 25-08-22- Once you find that the beginning of it has deformation, rust or broken problems must be timely correction. Generally speaking, the blade barbed rope will not be damaged simply, but it cannot be ensured that it will not happen. Because the local place where the blade barbed rope is required is generally outdoors, the probability of presenting an incident will be greatly increased. For example, in the plantation under the hillside, the blade barbed rope was damaged and deformed by stones rolling down the mountain, which requires manual correction in time, otherwise the deformed blade barbed rope will not only affect the beauty, but also lay hidden dangers for safety.

Latest articles

-

Galvanized hexagonal mesh features: easy to use; Save transportation costs. It can be reduced into small rolls, and involved in moisture-proof paper packaging, occupying little space. Coating thickness uniformity, corrosion resistance is stronger; Simple construction, no special technology; Strong resistance to natural damage and corrosion resistance and the ability to resist adverse climate impact; Can withstand a wide range of deformation and still not collapse. Play the role of fixed heat preservation and insulation.

-

-

-

-

-

They are good at expressing unspoken feelings to people. Their owners feel respect, dependence, admiration and affection. The process of caring for pets inspires people’s sense of responsibility, brings more meaning to people’s life, and helps people establish the fulcrum of life and confidence in life. In fact, dogs are very malleable animals. Through scientific and rational training, you can become a popular family member.

Whether you're a seasoned quilter, a professional seamstress, or a hobbyist looking to expand your sewing skills, a long arm stitching machine is a valuable tool to have in your arsenal. Its extended workspace, increased visibility, versatility, and advanced features make it a must-have for anyone who wants to take their sewing projects to the next level.

Conclusion

Industrial Sewing Machines A Backbone of Textile Production

5. Compatibility with Non-Standard Needles You may need specialized needles such as denim or leather needles when working with heavy fabrics. Ensure the sewing machine you choose can accommodate such needles for different types of sewing tasks.

In the production of denim garments, for instance, the double needle sewing machine is indispensable. The iconic double-stitched seams found on jeans not only contribute to the style but also ensure that the seams are strong enough to withstand the stresses of regular wear. It's also widely used in athletic wear and swimwear, where durability and flexibility are crucial.

A double needle sewing machine is equipped with a specialized needle that features two needle points on a single shank. This unique design enables the sewing machine to create two parallel rows of stitching simultaneously, which can add both functional and aesthetic value to sewing projects. The double needle is commonly used for hems, decorative stitching, and other applications where two lines of stitching are beneficial.

One of the primary benefits of using a double needle is its ability to create a parallel stitch effect, reminiscent of professional finishings often seen in ready-to-wear garments. This parallel stitching is not only aesthetic but also strengthens seams, making them more durable. This makes double needles particularly popular when working with knit fabrics, as they can help prevent the fabric from stretching or puckering during the sewing process.

4. Bernina 480 For those willing to invest in a high-end option, the Bernina 480 offers superior quality and versatility. It comes with a dual feed system that allows for seamless handling of heavy fabrics. Additionally, it features a robust selection of stitches, making it perfect for ambitious upholstery projects.

The double needle chain stitch sewing machine is a remarkable innovation in the textile industry, offering enhanced functionality and efficiency for various sewing applications. This machine, often used in garment manufacturing, is pivotal in producing high-quality seams that are both durable and aesthetically appealing. Understanding its mechanisms, benefits, and applications will shed light on why it is favored by professionals and hobbyists alike.

Furthermore, the geographical location and the availability of skilled technicians for machine maintenance and repair also influence prices. In regions where specialized services are scarce, the overall cost of owning an auto sewing machine may increase due to the added expenses of maintenance and repairs.

Four thread overlock machines are an essential piece of equipment for any sewing enthusiast or professional. These machines are designed to create finished, professional-looking seams on a variety of fabrics quickly and efficiently. If you are in the market for a new four thread overlock machine, you may be wondering about the price range you should expect to pay.

Hook needle upholstery, a traditional craft steeped in history, has evolved into a cherished technique for creating stunning and durable textile pieces. This unique method utilizes a specialized hook needle to manipulate fibers and fabrics, resulting in intricate designs and multidimensional textures. As we delve into the art and craftsmanship of hook needle upholstery, we uncover not only its historical significance but also its modern applications and enduring appeal.

In the world of sewing, single needle sewing machines stand out for their versatility, ease of use, and ability to handle a variety of fabrics. As a fundamental tool in both home sewing and the garment industry, the price of single needle sewing machines varies significantly based on a multitude of factors. Understanding these factors can help potential buyers make informed purchasing decisions.

The Rise in Popularity and Pricing of Fully Automatic Sewing Machines

Tips for Sewing with Heavy-Duty Thread

2. Juki TL-2010Q Known for its exceptional precision and speed, the Juki TL-2010Q features a walking foot and a heavy-duty frame. It is perfect for quilters and leatherworkers alike, making it a versatile choice for anyone interested in pursuing various sewing projects.

In the ever-evolving world of garment manufacturing, understanding operational costs is crucial for maintaining competitiveness and profitability. Among the myriad factors that contribute to these costs, the overlock machine rate plays a significant role. This article delves into what overlock machine rates are, their importance in the textile industry, and how manufacturers can optimize their costs.

Versatility and Applications

Moreover, these machines are generally simpler to operate than their electronic or computerized counterparts. While technology has undoubtedly advanced the sewing machine industry, some sewers prefer the straightforward nature of mechanical machines. The manual controls allow users to have more direct engagement with their project, fostering a deeper connection to the craft.

Conclusion

Moreover, these machines are designed with user-friendly interfaces, enabling even those with minimal sewing experience to operate them effectively. Features like LCD screens, programmable settings, and one-touch controls allow users to select various sewing patterns and adjust settings easily. This usability extends to maintenance, as many modern machines have built-in self-cleaning functions or easy access for manual cleaning.

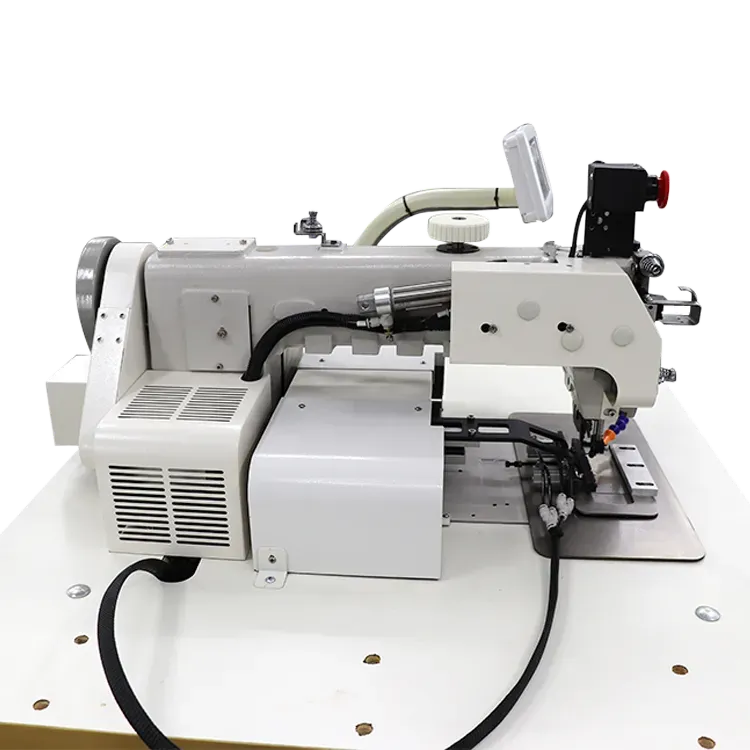

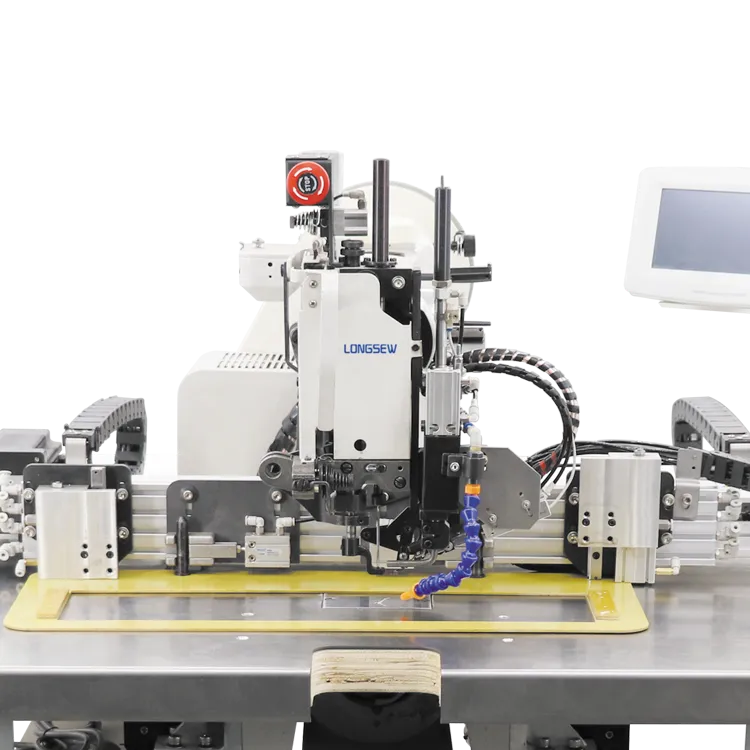

automatic button sewing machine

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged