wire mesh 50 x 50

Latest articles

wire mesh 50 x 50The most common barbed rope is 14*14 and 12*14 wire diameter barbed rope. The 14*14 wire diameter barbed rope is made of 200mm galvanized wire, and the barbed distance can be directly adjusted from 8-12cm. According to the different needs of each customer processing customized. Similarly, the length of each bundle of barbed rope can be cut from 50-250m as required. The 12*14 standard barbed rope is twisted by two different specifications of galvanized wire for 260mm and 220mm barbed wire. Other parameters are roughly the same except for different wire diameters. The price is slightly expensive because the latter uses more materials.

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read Morewire mesh 50 x 50

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read MoreCorrection is the hot galvanized wire or cold galvanized wire secondary treatment, the surface after correction is smooth and shiny, and the tensile strength is stronger, so that it is not easy to break. Now it is usually used for screen industry will be changed, which can improve the quality. In addition, clothes rack, communication, high voltage line will be changed to prevent breakage.

wire mesh 50 x 50...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read More

wire mesh 50 x 50The characteristics of galvanized hexagonal net: easy to use; Save transportation costs. It can be shrunk into small rolls and involved in moisture-proof paper packaging, taking up little space. Coating thickness uniformity, stronger corrosion resistance; The construction is simple and does not require special technology; Strong resistance to natural damage and corrosion resistance and adverse weather effects; Can withstand a large range of deformation, and still not collapse. It has the function of fixed heat preservation and insulation.

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read MoreTo walk the bird, the bird owner needs to take it out for a walk every day, not to stay in one place for a long time, in order to increase its activity.

wire mesh 50 x 50...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read Morewire mesh 50 x 50

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read Morewire mesh 50 x 50

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read MoreD, coating adhesion; The zinc layer of the plating parts should be firmly combined with the base metal with sufficient adhesion strength, and will not fall off or bulge after the hammer test.

wire mesh 50 x 50...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read More

wire mesh 50 x 50

Post time: 14-04-23...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read Morewire mesh 50 x 50

...

wire mesh 50 x 50 【wire mesh 50 x 50】

Read More

Popular articles

- Two, cold galvanized wire production process of galvanized. Galvanizing is the core process in the production of cold galvanized wire, mainly by soaking the steel wire in a molten zinc solution to form a zinc layer on its surface.

1. Zinc pot operators must stick to their posts

Pet cage from the use of material can be divided into plastic, wire, wire square tube, stainless steel four. General small animal cage multi-purpose is plastic and wire material, such as a lot of hamster cage, chinchilla cage are made of plastic or wire, small aquarium is plastic products, and the vast majority of small and medium-sized bird cage are wire products. The characteristics of this kind of small animal cage, is small, light, easy to carry, but also easy to clean care. For small animal cages, the wire diameter of the general iron wire is not very large, the thickness of the plastic is relatively thin, so the use of the time can not be “violent”, or the cage under the “destruction” will occur welding or plastic crack off.

Latest articles

-

Generally speaking, there are three kinds of anti-corrosion and anti-rust skills: surface dipping, spraying and surface galvanized, these three ways are to strengthen their anticorrosion ability and resist natural risks, extend their service life. Today we want to talk about the difference between dip plastic hook and galvanized hook.

-

Cold galvanizing is also called electric galvanizing. It is the use of electrolytic equipment to remove oil, pickling, and then put the pipe into the solution of zinc salt, and connect the anode of the electrolytic equipment, place zinc plate on the opposite side of the pipe, and connect the positive pole of the electrolytic equipment to the power supply. A layer of zinc is deposited on the pipe fitting by directional movement of an electric current from the positive pole to the negative pole. Cold plated pipe fitting is processed before galvanizing.

-

Post time: 25-05-22 -

Compared with other galvanizing processes, the cleaning requirements for low carbon steel wire before galvanizing are low. However, under the current trend of increasing the quality level of galvanized layer, some pollutants brought into the plating tank are obviously harmful. Because cleaning galvanized coating wastes a lot of time and reduces the production, it is very important to properly clean and effectively rinse the substrate before electroplating.

-

Stainless steel blade barbed wire production process is similar to galvanized blade barbed wire production process, usually according to the mold to determine the size of the blade.

-

Links

How often do you plan to use your sewing machine? Will it be an occasional hobby or a regular part of your creative endeavors?

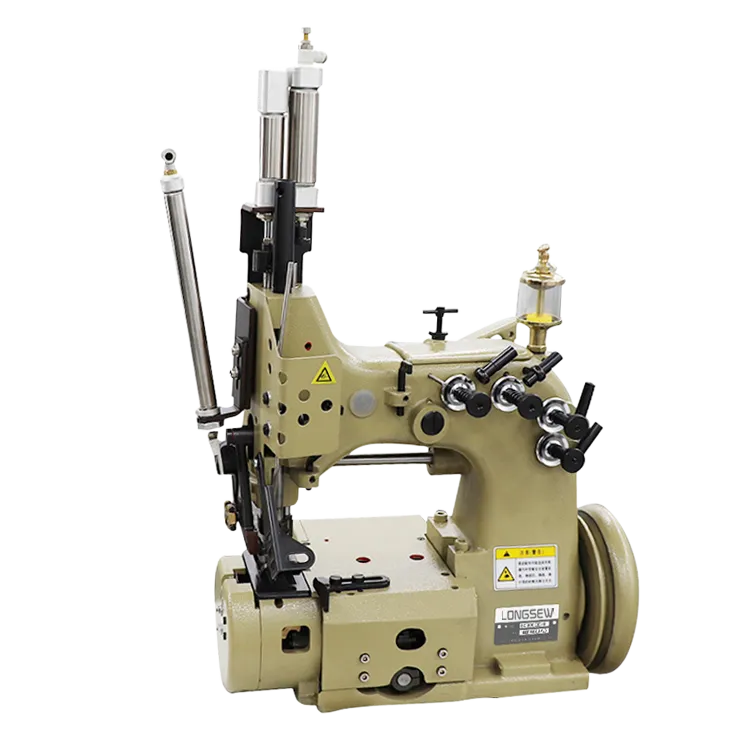

The bobbin shuttle hook is an essential part of sewing machines, particularly in the context of industrial and domestic textile manufacturing. Understanding its function and significance can provide valuable insights into the evolution of sewing technology and the precision required in the art of stitching.

It has been discovered that heavy-duty

It has been discovered that heavy-duty