wallboard screws

Latest articles

wallboard screws

...

wallboard screws 【wallboard screws】

Read MoreKnife width: 6 (mm)

wallboard screws...

wallboard screws 【wallboard screws】

Read MoreThree points should be selected before installation, which are the highest point (lowest) and the side line on both sides. The number of thorn rope column is good. When installing, it can be installed gradually according to the hook arrangement of thorn rope column.

wallboard screws...

wallboard screws 【wallboard screws】

Read More

wallboard screws

Post time: 18-05-22...

wallboard screws 【wallboard screws】

Read MoreThe optional height of this type of wire mesh is 1 meter, 1.2 meters, 1.5 meters, 1.8 meters, 2 meters. The latter three are the most commonly used, too low to achieve the fence protection effect. The mesh size is divided into 3 cm and 6 cm, and the vast majority of 6 cm is used.

wallboard screws...

wallboard screws 【wallboard screws】

Read MoreGalvanized hexagonal net is a galvanized metal wire mesh, the shape of the grid is hexagonal.

wallboard screws...

wallboard screws 【wallboard screws】

Read More

wallboard screwsThe use of electric welding mesh is very wide, can be used in many places. In the field of construction, especially the wall crack, has played a very important role, the traditional construction, is to put on mortar directly onto the wall, after such a long time, will appear fall off and fracture phenomenon, in order to prevent the occurrence of this phenomenon, must use welded wire mesh before rendering, welded wire mesh is fixed to the wall, above the plastering construction, Can ensure that the wall level for a long time, not easy to crack phenomenon.

...

wallboard screws 【wallboard screws】

Read Morewallboard screws

...

wallboard screws 【wallboard screws】

Read MoreMany pet carriers are designed with a small box in the base, so that pets can clean up when they poop. At the same time, it is also convenient for pet hygiene. For example, if there is no leakage of excrement in the box, pet excrement will be on the ground, which is quite unsanitary. If you have a box you can easily take it out and clean it out so it doesn’t get all over the place, so it’s more hygienic.

wallboard screws...

wallboard screws 【wallboard screws】

Read Morewallboard screws

...

wallboard screws 【wallboard screws】

Read More

Popular articles

1, galvanized wire mesh molding sheet must be packed with flat hard data, to avoid eternal deformation due to poor packaging. It IS VERY IMPORTANT THAT EACH PACKAGE AND ROLL OF RAW SHEET MATERIAL BE MARKED WITH PRODUCT NAME, STANDARD, QUANTITY, TRADEMARK, batch number, MANUFACTURER, DATE of production, STACKING SYMBOL, INSPECTOR CODE AND INSPECTION CERTIFICATE.

Galvanized wire is processed by low carbon steel wire rod. It is made of low carbon steel, after drawing forming, pickling and rust removal, high temperature annealing, hot dip galvanizing, cooling and other processes. Electrogalvanized iron wire using low carbon steel as raw materials, after drawing, galvanized and other processes completed. It has the characteristics of galvanized layer, strong corrosion resistance, strong galvanized layer, and so on. Galvanized iron wire is widely used in construction, highway walls, Zahua, weaving and other industries.

Hot wire mesh in the building wall engineering mainly played the anti-crack effect, inside and outside the use of specifications are not the same. Hot dipped wire material choose low carbon wire, through automation welding precision machinery processing after forming, surface treatment by zinc immersion process, galvanized barbed wire surface smooth and tidy, uniform structure strong, the overall performance is good, even if the local cutting or under pressure will not loose phenomenon occurs, it is the iron mesh strong anticorrosion performance in one of the widely used net class.

Latest articles

-

-

With a large pickpocket used for steel wire, into the zinc liquid before the surface of the zinc ash stirring; Use a small outlet for galvanized steel wire; Zinc pot steel wire outlet in 30 minutes, with pickpockets back and forth, until the large, floating zinc residue into brown, real zinc ash, zinc ash surface. The extracted zinc ash should be brown yellow real zinc ash, zinc surface, effectively reduce zinc consumption. This is one of the biggest steps to bring zinc consumption down, and it’s a real problem, one that hasn’t been solved for years.

-

-

The type of barbed rope is mainly reflected in the specification of the wire diameter, the thicker the diameter of the barbed rope produced is shorter, at the same time, the price is cheaper, mainly because the production efficiency is relatively high, because the price of the barbed rope is calculated according to the weight when it is sold. On the contrary, the finer the diameter of the wire, the longer the price is higher.

-

-

Three is to do a good job of galvanized silk product production site clean and tidy, in accordance with the scientific method of operation to operate the production, the operator should wear the required dress. If it is hot dip galvanized wire products, we must do a good job of passivation treatment, will be able to effectively prevent discoloration, prolong the method of discoloration, can solve the problem of discoloration.

Links

The Benefits of a 12 x 16 Metal Shed

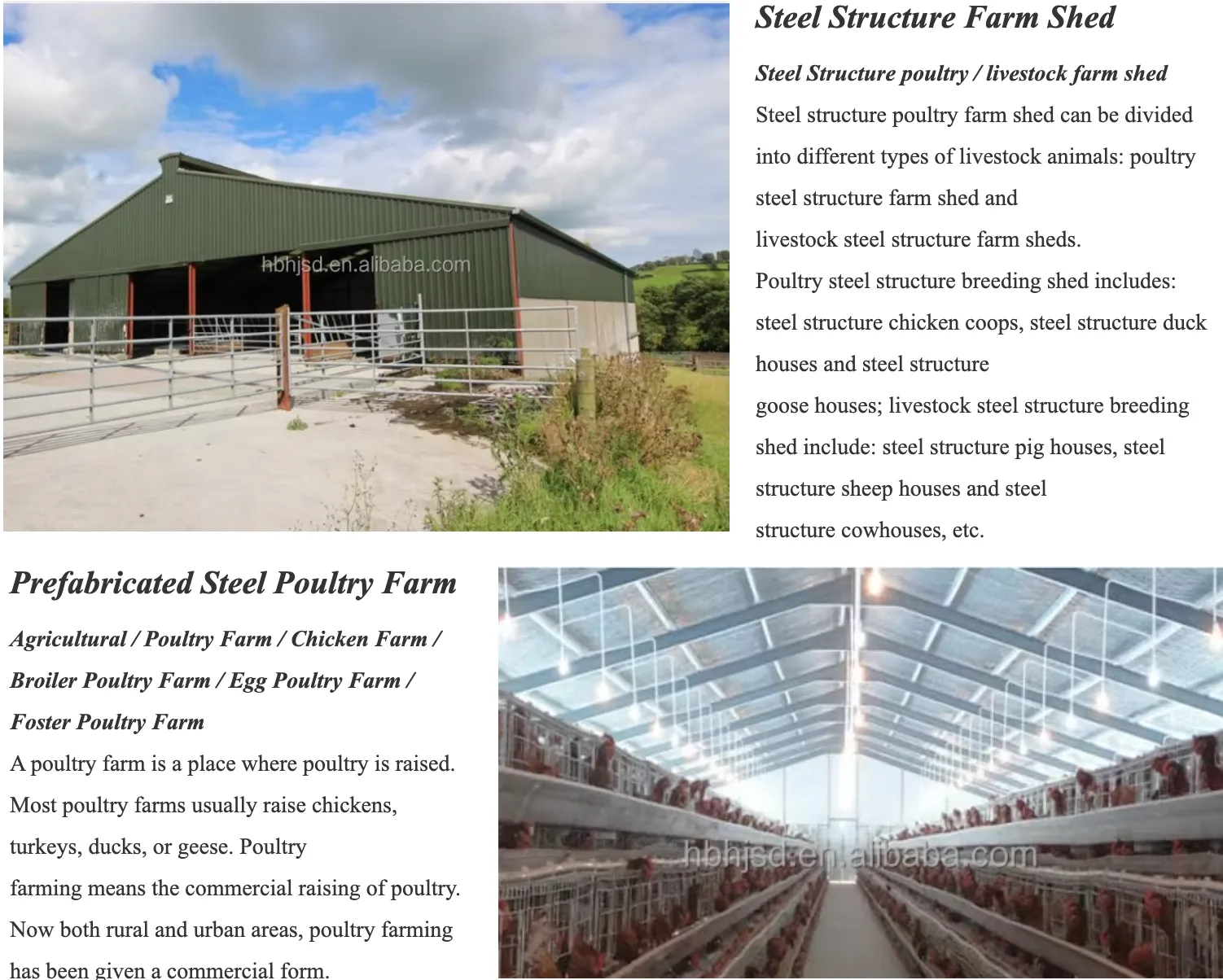

Now more than ever, farm building design prioritizes animal welfare. For example, modern livestock barns are equipped with advanced ventilation systems, climate control, and specific designs that enhance the well-being of animals. This shift aligns with consumer demand for ethical farming practices and quality assurance in food production. Farmers are increasingly aware that a comfortable and healthy environment for their livestock directly correlates with productivity and quality of produce.

Quality metal sheds also come in a variety of designs, sizes, and colors, allowing you to choose a shed that complements your property. Whether you need a small shed for gardening tools or a larger structure for equipment storage, you can find a metal shed that fits your specific requirements. Additionally, many manufacturers offer customizable options, allowing you to add windows, vents, or shelving to create a personalized space.

Additionally, the speed of construction using steel beams can drastically reduce labor costs. Because steel components are prefabricated, they can be quickly assembled on-site, cutting down the time it takes to complete the warehouse. Faster construction means that businesses can begin operations sooner, which can lead to increased revenue.

Farm buildings are indispensable to modern agriculture. They facilitate efficient operation, support sustainable practices, and are continuously evolving with technological advancements. As the global population continues to rise, the demand for food will intensify, making the role of farm buildings even more critical. By investing in innovative designs and sustainable practices, the agricultural industry can continue to meet these challenges head-on while ensuring the welfare of livestock and the environment. Ultimately, the evolution of farm buildings reflects the broader transformation of agriculture, driving us towards a more sustainable and productive future.

Additionally, metal buildings are highly customizable. Whether you require a small workshop for personal projects or a large facility for commercial use, metal structures can be designed to meet your specifications. Options include various sizes, layouts, and finishes, enabling you to create a workspace that suits your particular needs.

Modern Advancements in Industrial Shed Frames

Incorporating safety features into metal buildings is relatively straightforward, making them an ideal choice for warehouses and office spaces alike. The robust nature of steel provides enhanced protection against fires, pests, and environmental hazards. Additionally, the ability to install advanced security systems, such as surveillance cameras and access controls, further boosts the security of these facilities. Companies can operate with greater peace of mind, knowing their assets and employees are secure.

In conclusion, the farm equipment barn is far more than a simple storage facility; it is integral to the functionality, safety, and efficiency of modern agriculture. As farms adapt to new technologies and methods, these barns continue to evolve, demonstrating their critical role in supporting farmers and their operations. Properly designed and maintained barns not only protect valuable equipment but also contribute to the overall success of agricultural endeavors. For farmers, investing in a well-thought-out farm equipment barn is an investment in the future of their farming operations, ensuring they are equipped to meet the challenges of a rapidly changing agricultural landscape.

Advantages of Prefabricated Steel Structures