construction mesh screen

Latest articles

construction mesh screen

...

construction mesh screen 【construction mesh screen】

Read More

construction mesh screenWhen the large roll galvanized wire galvanizing process coating foaming, first check the bath temperature. If the bath temperature is not low, then strengthen the plating before removing oil, prevent the matrix metal in acid corrosion. If you pay attention to these problems, the foaming phenomenon still exists, it should pay attention to the amount and quality of additives, then you can stop adding additives, with high current electrolysis for a period of time, in order to reduce the content of additives, observe whether the foaming phenomenon is improved. If there is still no improvement, it is necessary to check whether the storage period of additives is too long, or whether there are too many impurities in the additives.

...

construction mesh screen 【construction mesh screen】

Read MoreThe purpose of checking on time is to find problems in time. Users should go to the inspection on time if they can not install the blade barbed rope and ignore it. Local rust should be removed in time and local deformation should be corrected in time, and the service life of the blade barbed rope should be extended.

construction mesh screen...

construction mesh screen 【construction mesh screen】

Read More

construction mesh screen

Post time: 17-06-24...

construction mesh screen 【construction mesh screen】

Read More

construction mesh screenThe quality of hot-dip galvanized barbed wire is only good in the surface of the wire attached to the galvanized layer, and with the chemical reaction, the surface of the zinc layer will gradually lose effect because of the oxidation reaction, this situation is more prominent in the humid area of the environment. And because after all, it is rusty iron wire, so the quality of hot-dip galvanized barbed rope is certainly not up to the level of stainless steel barbed rope.

...

construction mesh screen 【construction mesh screen】

Read Moreconstruction mesh screen

...

construction mesh screen 【construction mesh screen】

Read MoreBecause the size of the plane or the surface of the urban area is relatively small, many sports arenas are built in the more prosperous and lively sections, with hexagonal nets to protect the barrier, so it greatly reduces the spherical three-dimensional flying out of the field so affect the traffic order of the bad things.

construction mesh screen...

construction mesh screen 【construction mesh screen】

Read More

construction mesh screen

Post time: 26-10-22...

construction mesh screen 【construction mesh screen】

Read Moreconstruction mesh screen

...

construction mesh screen 【construction mesh screen】

Read Moreconstruction mesh screen

...

construction mesh screen 【construction mesh screen】

Read More

Popular articles

The anticorrosion of these raw materials are very different, the use of life is not the same. Cattle fence cold galvanized, also known as electroplating, galvanized little, rust in rain, but the price is cheap, the use of life in 5-6 years. Hot dip galvanizing (low zinc and high zinc) zinc content in 60 grams to 400 grams, the use of life is about 20-60 years, corrosion resistance is general.

Hot plating wire can generate thicker coating, and there are both pure zinc layer and iron zinc alloy layer, so the corrosion resistance is better. The production power of hot dip galvanizing is particularly high, and the duration of the parts in the hot dip galvanizing tank usually does not exceed lmin. Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. To plate, tape, wire, tube and other profiles plating, automation degree is higher.

Hot-dip galvanized wire is widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, electric power transmission, shipbuilding and other industries. It has been widely used in recent years in agricultural fields such as agricultural medicine sprinkler irrigation, greenhouse and construction industry such as water and gas transmission, wire casing, scaffolding, Bridges, highway guardrail and so on.

- The dog cage is a resting place for the dog, do not put it in the place where the family is walking, teach the children, when the dog is in the cage, do not disturb the dog.

Latest articles

-

1. It is used for enclosure breeding, road isolation, and large-scale breeding enclosure protection. It is recommended that you choose a product with a wire diameter of 3mm.

-

-

The strength of the hook mesh should be satisfied: when the vehicle is traveling at 80 kilometers per hour, the hook mesh will not fall into the river when it bumps against the rail at a 15 degree Angle. The shape and color of the hook mesh should be in harmony with the surrounding natural environment. The phenomenon planning of the important Bridges should be done well. When the bridge crosses important traffic lines, such as expressways, urban rail transit, expressways, railway trunk lines, etc., the hook mesh should add the protective mesh on the pavement of the bridge deck.

-

-

The surface of alluvium before hot dip galvanizing of orchard special electric galvanized shaft wire can partially remove the surface film layer, surface impurity and other shortcomings according to the basic technology to find and solve; Excessive foam is caused by soap and soapable surface active substances such as human fat into the tank. A moderate rate of foam production would be fine. There are many fine homogeneous particles in the tank, can stabilize the foam layer, with activated carbon mat to remove surface active substances. Or make the bubble unstable according to overworry, these are all reasonable countermeasures; Other strategies should also be used to reduce the amount of surface-active substances introduced. The introduction of organic matter can make the electroplating process speed drop sharply. Although the secret recipe of organic chemistry is beneficial to the high accumulation rate, the thickness of the coating can not meet the requirements after the organic matter is brought in, so the activated carbon can be used to solve the tank.

-

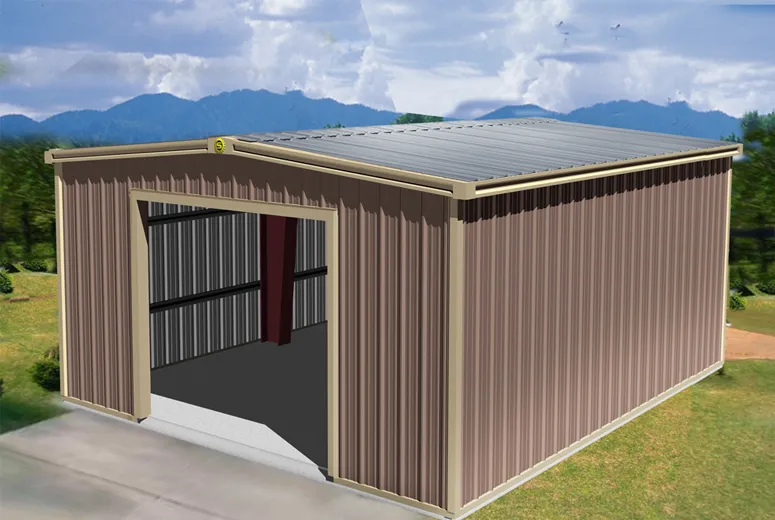

Another key benefit is the environmental factor

. Many metal office sheds are constructed with recyclable materials, and their energy-efficient features can lead to lower utility bills. By investing in eco-friendly solutions such as solar panels or rainwater harvesting systems, you can further reduce your carbon footprint while enjoying a modern workspace.metal office shed

The steel used for the frame, wall panels, and roofing system is resilient to fire, wind, moisture, and mold. Insulated wall or ceiling panels offer superior thermal protection capabilities, helping maintain interior climate control regardless of external weather conditions. This keeps employees comfortable and stored items safe, which leads to greater customer satisfaction.

Conclusion

In conclusion, prefabricated industrial buildings represent a groundbreaking shift in the construction sector, offering a multitude of benefits ranging from speed and cost savings to sustainability. As the industry continues to grapple with the challenges of climate change and economic pressures, prefabrication stands out as a viable solution that meets the needs of modern businesses while promoting responsible and sustainable development practices. As technology advances and the acceptance of these building methods grows, the future looks bright for prefabricated industrial buildings, cementing their place as a cornerstone of efficient construction in the years to come.

Compliance with Codes and Standards

While functionality is crucial, the aesthetic appeal of a steel frame barn house cannot be overlooked. These structures often combine a rustic exterior with sleek, modern interiors, creating a visually striking contrast. The use of steel complements traditional barn features, such as vaulted ceilings and large entryways, while also introducing a contemporary edge. Homeowners can personalize their barn houses with various finishes, including wooden siding, metal roofing, and expansive windows, allowing them to create a space that reflects their individual taste.

steel frame barn house

A warehouse is a great building to own: they’re versatile, and can be used for anything from storage to industrial use. But why should you opt for a steel building for your next warehouse?

Security Features

One of the most appealing aspects of metal barns is their durability. Unlike wooden structures, which are susceptible to rot, pests, and weather damage, metal barns are designed to withstand the rigors of time and nature. They resist the challenges posed by extreme weather conditions, including heavy rains, snow, and high winds, making them an ideal choice for agricultural settings in diverse climates.

Steel has emerged as a favorite material among builders and architects due to its numerous advantages. First and foremost, steel provides exceptional structural integrity. Unlike traditional materials such as wood or concrete, steel can withstand harsh environmental conditions, including extreme weather, earthquakes, and pests. Its inherent strength allows for the construction of taller buildings with larger open spaces, providing both aesthetic appeal and functionality.

Despite their many advantages, there are considerations to keep in mind when opting for a steel portal shed. Local building codes and zoning laws must be adhered to, which may affect the construction process. Moreover, while steel provides strength and durability, proper insulation is essential in areas with extreme temperatures to ensure comfort and efficiency.

Cost-Effectiveness

A steel structure warehouse design requires careful consideration of multiple design aspects. Factors such as weight capacity, pressure resistance, material strength, tensile strength, and load transfer must be considered. The thickness of the steel must also be determined to ensure the structure is strong and functional. A comprehensive process must ensure all these questions are answered and that the warehouse is built to the highest standards.

The design of the steel structure warehouse has been carefully considered to minimize the potential for damage. Additionally, this construction method facilitates regular maintenance and increases the structure’s longevity.

For many users, security is a top concern when it comes to storage. Metal sheds offer superior security features compared to their wooden counterparts. Their robust construction can deter thieves and provide a safe place to store valuable tools, equipment, or seasonal items. Many metal sheds come equipped with secure locking mechanisms and can even be customized with additional security features such as alarms or surveillance systems.

all metal sheds

5. Energy Efficient

One of the primary benefits of a 6x4 metal shed is its superior durability compared to wood or plastic alternatives. Constructed from galvanized steel or aluminum, metal sheds are resistant to rust, rot, and pests, making them ideal for long-term outdoor use. Their robust construction also provides an added level of security. With a sturdy lock, you can ensure that your equipment, tools, or other valuables are well-protected against theft and vandalism. Unlike wooden sheds that can be compromised by termites and other pests, metal sheds offer peace of mind for homeowners.

Far from being eyesores, modern small metal barns come in various styles and finishes, making it easy to choose one that complements your property’s aesthetic. Available in various colors, roofing styles, and window placements, buyers can find a barn that enhances, rather than detracts from, the visual appeal of their land.

One of the standout features of a metal shed is its resilience against the elements. Crafted typically from galvanized steel or aluminum, metal sheds are built to withstand harsh weather conditions including rain, snow, and intense sunlight. Unlike wooden sheds that can rot, warp, or attract pests, a metal shed remains strong and stable over time. This is particularly beneficial for those who live in areas with extreme weather fluctuations, as the durability of metal sheds ensures that your tools and equipment are protected year-round.

Before you embark on the exciting journey of building your custom metal garage, it is important to consider local zoning laws and building regulations. Depending on where you live, you may need specific permits to construct a metal building. Checking with local authorities can save you time and potential legal issues down the line.

Easy Assembly and Scalability

A fully functional workshop requires access to utilities such as electricity, water, and sewage. The cost of bringing these services to a site can be substantial, especially if the location is remote or lacks existing infrastructure. Businesses should factor in these costs when budgeting for a steel workshop.

In summary, investing in a metal garage kit is an excellent decision for anyone seeking a cost-effective, durable, and versatile solution to their storage and workspace needs. With savings of 30% to 40% compared to traditional construction, along with the benefits of low maintenance and quick installation, metal garage kits present a compelling option for homeowners and business owners alike. Whether you're a DIY enthusiast or someone seeking a hassle-free solution, a metal garage could be the perfect addition to your property.

Weekly disinfection should involve cleaning all surfaces, including walls, floors, and equipment, with a suitable disinfectant. This routine helps to eliminate harmful bacteria, viruses, and fungi that can cause diseases. Additionally, using high-pressure washers can aid in removing stubborn dirt and biofilms that harbor pathogens. Regular disinfection not only promotes a healthy environment but also extends the lifespan of the steel structure factory used for the coop.

In recent years, the construction industry has seen a significant shift towards the use of prefabricated metal buildings. This trend is largely driven by the versatility, speed of assembly, and cost-effectiveness that these structures offer. Large prefabricated metal buildings are becoming increasingly popular in various sectors, ranging from agricultural to commercial applications, and even in the industrial realm.

Horses are sensitive creatures that require protection from extreme temperatures, whether it be blistering heat or frigid cold. Galvanized horse shelters provide a refuge where horses can seek shade in summer and shelter from rain, snow, and wind in winter. By creating a controlled environment, these shelters help reduce the risk of health issues related to exposure, such as colds or heat stress. Additionally, ensuring horses have access to shelter can promote better overall behavior and reduce stress, leading to happier and healthier animals.

In today’s environmentally conscious market, sustainability is more important than ever. Steel structures can be designed for energy efficiency, utilizing innovative insulation techniques and sustainable materials. Additionally, steel is 100% recyclable, meaning that at the end of a building’s life, the materials can be repurposed without losing quality. This feature aligns with global efforts towards reducing waste and minimizing the carbon footprint of new constructions.

In conclusion, the narrow metal shed serves as an invaluable asset in today’s fast-paced world, where efficient use of space and minimal maintenance are paramount. By investing in one of these sturdy structures, homeowners can enjoy a clutter-free and organized garden or yard while ensuring that their belongings are protected from the elements and potential theft. With their durability, versatility, and aesthetic appeal, narrow metal sheds are not just storage solutions; they are key players in enhancing the overall functionality and enjoyment of outdoor spaces. Whether you are an avid gardener or simply in need of extra storage, a narrow metal shed could very well be the answer you’ve been seeking for your outdoor storage needs.

1. Cost Efficiency One of the primary advantages of prefab buildings is their cost effectiveness. The construction process is streamlined, reducing the labor hours and material wastage typical of conventional building methods. By opting for a 30x30 prefab building, homeowners and businesses can save significantly on both construction and maintenance costs.