black welded wire fence roll

Latest articles

3, barbed rope protection net in the bridge, channel, should be toward the bridge head cone slope (or end wall) direction surrounded, should not leave for people, livestock can drill into the gap.

black welded wire fence roll...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence roll

Post time: 07-02-23...

black welded wire fence roll 【black welded wire fence roll】

Read Moreblack welded wire fence roll

...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence roll

Post time: 11-05-23...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence rollAs we all know, the purpose of painting the fence fence factory is to make the product better anti-corrosion effect. So what should we pay attention to in the product painting?

...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence rollIn order to orchard special electric galvanized shaft wire in alluvial surface to partially remove the surface film layer, surface impurity and other shortcomings can be found and solved according to the basic technology; Excessive foam is caused by soap and soapable surface active substances such as human fat into the tank. A moderate rate of foam production would be fine. The large amount of fine homogeneous particles in the tank can stabilize the foam layer, but the accumulation of too much solid particles will cause explosion.

...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence roll

Post time: 29-08-22...

black welded wire fence roll 【black welded wire fence roll】

Read Moreblack welded wire fence roll

...

black welded wire fence roll 【black welded wire fence roll】

Read More

black welded wire fence rollFirst, the effect of tensile strength or hardness of steel wire

...

black welded wire fence roll 【black welded wire fence roll】

Read Moreblack welded wire fence roll

...

black welded wire fence roll 【black welded wire fence roll】

Read More

Popular articles

- Suitable for general engineering building wall, pouring concrete, multi-storey building, etc., in the structure of heat preservation and heat insulation system plays an important role, when the construction will be hot dip galvanized welded wire rack together wall of heat preservation and heat insulation board placement will be concrete pouring mold inside, outside the wall heat preservation and heat insulation board and one kind of live, after ripping into heat preservation and heat insulation board and wall body. The coating on the surface of the welding core is called the coating.

And high-quality data are constrained by production costs and production conditions, so some electric welding mesh manufacturers do not meet this requirement, in this case, there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

Latest articles

-

Post time: 29-01-23 -

1. Zinc pot operators must stick to their posts

-

Post time: 21-04-23 -

-

1. The waterproof layer at the bottom of the cage should be checked regularly to prevent leakage at the bottom and replaced in time to avoid dropping liquid objects such as bird droppings, urine and water, resulting in corrosion of the cage edge.

-

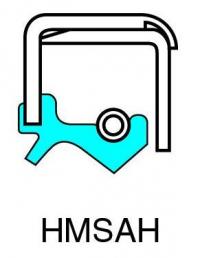

These devices can detect changes in pressure, temperature, or vibration that may indicate a problem with the seal or the hub itself These devices can detect changes in pressure, temperature, or vibration that may indicate a problem with the seal or the hub itself

These devices can detect changes in pressure, temperature, or vibration that may indicate a problem with the seal or the hub itself These devices can detect changes in pressure, temperature, or vibration that may indicate a problem with the seal or the hub itself

Signs of a failing gasket include oil stains on the engine, a burning oil smell, or a drop in oil level Signs of a failing gasket include oil stains on the engine, a burning oil smell, or a drop in oil level

Signs of a failing gasket include oil stains on the engine, a burning oil smell, or a drop in oil level Signs of a failing gasket include oil stains on the engine, a burning oil smell, or a drop in oil level