gypsum screw size

Latest articles

Pressure welded steel grid plate is the steel grid plate fixed by pressure resistance welding at each intersection of bearing flat steel and transverse bar, which is called pressure welded steel grid plate. Torsion torsion square steel is generally used for cross bar of pressure welded steel grid. Although they do not belong to the same variety, but in the steel lattice plate standards and performance are still the same.

gypsum screw size...

gypsum screw size 【gypsum screw size】

Read More5, after the light plating should be carried out light treatment.

gypsum screw size...

gypsum screw size 【gypsum screw size】

Read More2, the cage must be strong

gypsum screw size...

gypsum screw size 【gypsum screw size】

Read Moregypsum screw size

...

gypsum screw size 【gypsum screw size】

Read More

gypsum screw sizeThe iron wire used for the barbed wire is woven or welded into low carbon steel wire, medium carbon steel wire, high carbon steel wire, stainless steel wire and other materials. Production process: general braided, embossed braided and spot welding. If the material is steel wire, after equipment processing into a network, it is called wire mesh.

...

gypsum screw size 【gypsum screw size】

Read More

gypsum screw sizeNational standards on the use of wire mesh standards have certain requirements, diameter and mesh size matching use, rather than simply diameter, on the plaster layer to use the mesh should not be greater than 20×20, diameter is not easy to be less than 1mm, just choose diameter is not much meaning, choose 40×40×0.9 and choose 10×10×0.6 wire mesh, Which is better? I’m afraid it’s 10 by 10 by 0.6.

...

gypsum screw size 【gypsum screw size】

Read More

gypsum screw size1. Used for mountain farming, road isolation, large farming enclosure protection, it is recommended that you choose 3mm wire diameter products.

...

gypsum screw size 【gypsum screw size】

Read Moregypsum screw size

...

gypsum screw size 【gypsum screw size】

Read More

gypsum screw sizeIn the calculation process of 12*14 specifications of barbed rope, it can not be calculated according to the above calculation formula, because first of all, two specifications of raw materials are used, the thinner the wire diameter, the higher the processing cost. Generally speaking, a kilogram of 12*14 barbed rope can reach about 7.5 meters, and the ratio of warp wire to barbed rope cannot be calculated according to the traditional ratio of 7 to 3. The specific use of how much wire and silk need to go through a series of professional measurement but also increase the loss of raw materials and other factors to calculate. Thorn rope factory will also according to customer needs to calculate the reasonable amount of customer use.

...

gypsum screw size 【gypsum screw size】

Read Moregypsum screw size

...

gypsum screw size 【gypsum screw size】

Read More

Popular articles

Advantages: The cost of hot dip galvanized rust prevention is lower than that of other paint coating. In suburban environment, the standard hot-dip galvanized rust prevention thickness can adhere to more than 50 years without repair. In urban or offshore areas, the standard hot-dip galvanized rust protection layer can last 20 years without repair. Galvanized layer and steel is a metallurgical connection, into a part of the steel surface, so the durability of the coating is more reliable.

A barbed rope is literally a kind of barbed rope. Generally speaking, the material is made of iron wire or copper wire. People have a very long history of using barbed ropes, as early as the 19th century Americans began to use the first barbed ropes. Function: Its first function is agricultural fence. The origin of the thorn rope is in agriculture. People used the thorn rope to divide the fields into different pieces. Barbed wire is also widely used in fencing until now. Secondly, it is used for protection and protection. For example, people put barbed ropes around the walls of their houses to prevent people from climbing over the walls and entering the yard. There are many other functions such as fire prevention and theft prevention.

- Secondly, galvanizing can increase the mechanical strength of the product. The wire drawing process is to draw metal materials to make their grains thinner, thereby improving the mechanical strength of the product. Galvanizing can form a layer of zinc on the surface of the product, and the zinc layer itself has a high hardness, which can provide additional support during the wire drawing process and prevent the metal material from tensile fracture during the wire drawing process. Therefore, galvanized products after wire drawing can increase their strength and stiffness, and improve their tensile strength and torsional resistance.

Post time: 23-05-22Some raw materials in the production of unstable processing, the wire itself will exist burr, surface small pits and other local defects. Galvanized steel in galvanized, generally should pay attention to the galvanized layer protection time of galvanized wire, and the thickness of galvanized layer has a great relationship. Generally speaking, when the main gas is relatively dry and used indoors, the galvanized layer thickness of galvanized wires is only 6-12μm, and under relatively harsh conditions, the galvanized layer thickness of galvanized wires needs 20μm, and can be predicted to reach 50μm.

The blade gill net has 3-7 buckles every 2 turns, and it is a circle card. After being opened, it forms a spiral shape. When stretching, you must take protective gloves to prevent scratches. When opening, only one side of the gill net needs to be fixed, and then the gill net needs to be opened in the opposite direction. Pay attention to the spacing of the holes should not be too large, otherwise it will affect the aesthetic effect. As long as the time to slowly return to the line, simple operation, convenient construction.

Latest articles

-

-

Galvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

-

-

There are still some differences between electric mesh and wire mesh and steel mesh. This mesh is mainly a welding mesh made of high quality low carbon steel wire after straightening and cutting, and then welded by electric welding equipment. It can be said that because of the characteristics of fast production and convenient transportation, it has been applied in many industries. In today’s construction projects, people can also see the image of this network well. The application of welded mesh in this industry is mentioned because of its strong corrosion resistance and uniform mesh. It has become a special grid for floor heating in construction industry and has been applied in many fields.

-

D, coating adhesion; The zinc layer of the plating parts should be firmly combined with the base metal with sufficient adhesion strength, and will not fall off or bulge after the hammer test.

-

Post time: 24-08-22

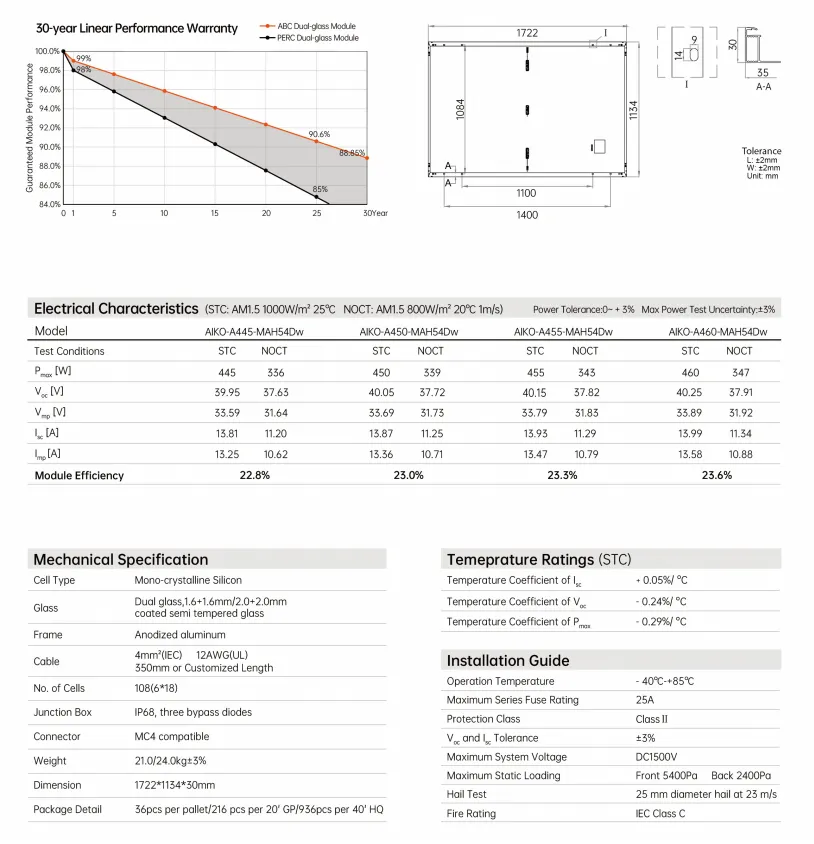

In recent years, the urgency to transition to renewable energy sources has become increasingly apparent. The growing concern over climate change, coupled with the depletion of fossil fuels, has driven innovation in solar technology. One of the most exciting advancements in this field is the development of bi-solar panels. These innovative energy solutions are set to revolutionize how we harness solar energy, making it more efficient and versatile than ever before.

4. Battery Compatibility Since hybrid inverters are often paired with battery storage systems, the compatibility with different battery types can affect pricing. Many hybrid inverters are designed to work with specific battery solutions, and if a user has a preferred battery brand, this may influence the overall system’s cost.

3. Grid Dependency On-grid systems are reliant on the utility grid. During power outages, the system will not provide electricity to your home unless there is battery backup, which is a separate investment.

As the world increasingly turns its focus towards renewable energy solutions, solar power continues to be one of the most promising alternatives to fossil fuels. Among the latest advancements in solar technology are bidirectional solar panels, designed to optimize energy generation and enhance the efficiency of solar power systems. In this article, we will explore what bidirectional solar panels are, how they work, and the potential benefits they offer in the transition towards a more sustainable energy future.

Key Factors Affecting Solar Panel Costs

While the initial cost of purchasing solar panels can be significant, the long-term savings often make solar energy a more economical choice. The JA Solar 540W panels provide a high energy yield, which can lead to lower electricity bills and a quicker return on investment. Many governments and local authorities offer incentives, tax credits, and rebates for solar installations, further enhancing the financial appeal for potential buyers. Over time, the reduction in utility costs can result in considerable savings, making solar energy not just a sustainable choice, but a financially savvy one as well.

While traditional solar panels are rectangular, newer designs have emerged that offer flexibility in terms of dimensions and aesthetics. Bifacial panels, for example, can capture light from both sides, potentially increasing energy efficiency without necessarily requiring more roof space. Moreover, building-integrated photovoltaics (BIPV) offer solar solutions that double as roofing materials, allowing homeowners to integrate solar technology seamlessly into their home's design.

This week, the solar panel market was affected by the upstream, and the price continued to fall.

Optimizing Power Generation

However, if some of your items are already solar-powered (like the appliances and wearables we mentioned earlier), then you’ll have more solar power available for items needing external power sources!

One of the most compelling reasons to invest in solar panels for your home is their ability to produce clean, renewable energy. Unlike fossil fuels, solar energy is abundant and inexhaustible. By installing solar panels, homeowners can take advantage of this natural resource, reducing their reliance on non-renewable energy sources that contribute to pollution and climate change.

Factors Influencing Solar Panel Prices