1 3 4 stainless steel coil nails

Latest articles

1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read MoreThe purpose of checking on time is to find problems in time. Users should go to the inspection on time if they can not install the blade barbed rope and ignore it. Local rust should be removed in time and local deformation should be corrected in time, and the service life of the blade barbed rope should be extended.

1 3 4 stainless steel coil nails...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read MoreThe most obvious gap in a short time is the cross section of this piece, hot dip galvanized barbed wire because it is the surface anti-corrosion treatment, so in the cross section of this piece will appear rust, and stainless steel barbed wire because the internal raw materials and surface raw materials are consistent, so there is no such situation.

1 3 4 stainless steel coil nails...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More

1 3 4 stainless steel coil nails

Post time: 17-02-23...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More

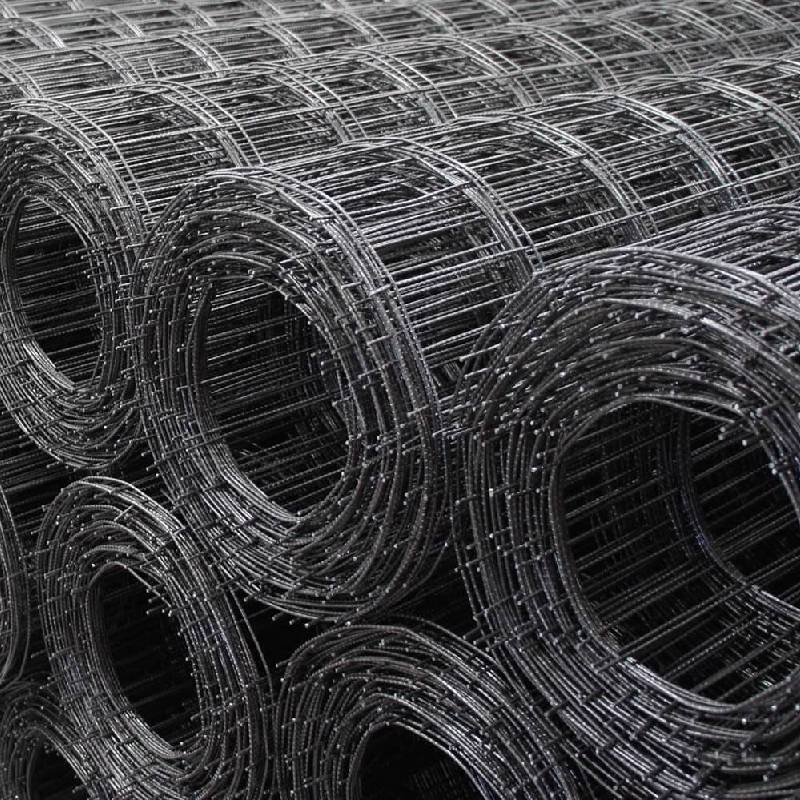

1 3 4 stainless steel coil nailsThere are many categories of large rolls of galvanized wire, and different categories can be applied to different scenarios. The common application of galvanized iron wire is the application of the construction industry. One is the use of binding wire. Whether it is the binding of scaffolding or reinforcement, galvanized iron wire is needed to carry out. There are also 20kg or 50kg bundles of No. 18, No. 16, No. 14, No. 12, No. 10 galvanized coils.

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More1 3 4 stainless steel coil nails

...

1 3 4 stainless steel coil nails 【1 3 4 stainless steel coil nails】

Read More

Popular articles

Now it is more used in the binding of the construction industry. Compared with ordinary iron wire, it is softer and has better luster. Use in daily life does not need to carry out maintenance and maintenance, save a lot of time, but also save the cost of maintenance and maintenance. Annealed wire has good stability, good corrosion resistance, greatly prolonging the service life. More kinds, can be selected according to different uses, making annealing wire device is simple, improve the utilization rate of the device. The material properties of annealed wire can meet different processing requirements.

Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

In the installation of barbed rope, it is easy to cause incomplete stretch caused by winding, and the installation effect is not very good. At this time, it is necessary to use tensioner for stretching.

- Although galvanized hook mesh is outstanding because of its surface, this does not mean that this hook mesh product is not useful. From the point of view of people’s use of it, this hook mesh products through a surface of galvanized treatment, whether it is wind and sun, or man-made inadvertent damage, will not bring a little harm to it, so the more comprehensive use of galvanized hook mesh products will then be widely used in several fields.

Latest articles

-

Stainless steel blade barbed wire production process is similar to galvanized blade barbed wire production process, usually according to the mold to determine the size of the blade.

-

1, the width and length of the hexagonal net (according to your actual needs, the width and length we can adjust flexibly).

-

-

Regular maintenance and maintenance, save a lot of time, but also save the cost of maintenance and maintenance. With good stability, corrosion resistance, greatly prolong the service life. There are many kinds, which can be selected according to different uses. The device for making annealed wire is simple, and the utilization rate of the device is improved.

-

The screen is made into a box-like container, with stone filled with cages, can be used to protect and support seawall, hillside, road and bridge, reservoir and other civil engineering, flood control and flood resistance is a good material.

-

Galvanized wire coating rough, passivation film is not bright, bath temperature is too high. If the cathode current density is too high, zinc content in the bath is too high or sodium hydroxide and DPE content is too low; Electroplating solution with solid particles or excessive foreign metal impurities, will lead to such problems. Solution: If the large roll galvanized wire to the above coating is rough, there may be solid particles in the plating solution. If the roughness of the part is severe, the current density may be too high.

Links

275% Veggrør for bedre byggekvalitet

Machined springs have a constant slot dimension, thus, there exists a slot width at both ends that does not close. When that dimension is added to the solid structural end, you’ll find that a machined spring used in compression is longer than an equivalent wire spring. This means that a machined spring cannot be configured to provide the same performance of a wire spring used in compression. Hence, in compression springs, equivalent machined springs are always longer than wire ones.

Early detection and resolution of problems can improve the lifespan and performance of compression coil springs.

결론적으로, HY-RIB 공법은 현대 건축과 토목 분야에서 구조 접합의 새로운 표준을 제시하고 있다. 간편한 시공과 뛰어난 내구성 덕분에 많은 건축 및 토목 프로젝트에서 채택되고 있으며, 앞으로도 지속적으로 발전해 나갈 것으로 기대된다. HY-RIB 구조는 건축물의 안전성과 효율성을 높이는 데 기여하며, 우리 삶의 질 향상에 중요한 역할을 할 것이다.

Precision. In general, machined springs can be made to precise dimensions more easily than wire springs. Both wire wound and machined springs readily offer a precision of 10%. Machined springs can offer 1.0% precision. Wound springs can too, when statistical methods are used for selection. A finer precision of 0.1% is probably not available from wire wound springs and only available from machined springs using post-processing techniques.

Another essential aspect of compression spring design is the consideration of fatigue life. Springs are subject to cyclic loads, which can lead to material fatigue over time. The fatigue strength of the selected material must be evaluated, and often, a factor of safety is introduced to account for unexpected loads or variations in material quality.

A coil spring is a mechanical device made from elastic materials, such as metal wire, coiled into a helical shape. This design enables the spring to compress, extend, or rotate under load and then return to its original shape once the load is removed. The properties of coil springs allow them to store energy temporarily and release it as needed, providing solutions for managing force and motion in mechanical systems.

Moreover, advancements in modeling technologies and materials science have facilitated the design of custom double helical springs tailored to specific operational requirements. Many manufacturers now offer bespoke solutions, allowing businesses to optimize their products for efficiency and effectiveness. This trend is particularly relevant in competitive industries where innovation and performance can set a company apart from its rivals.

In addition to automotive and electronics, light compression springs play a crucial role in industrial machinery. They are found in assembly lines, packaging equipment, and conveyor systems, where they help facilitate movement and improve efficiency. In medical devices, these springs are utilized in syringes, infusion pumps, and diagnostic equipment, ensuring reliable operation and user-friendly design.

Danley Dowel Cradle Innowacja w budowie i transporcie

2. Quantity Purchased Buying in bulk often reduces the price per square foot. Builders might find that sourcing wire mesh for larger projects can lead to significant savings compared to purchasing smaller quantities for multiple jobs.

3. Local Market Variations Prices can fluctuate based on local market conditions, including the availability of materials and competition among suppliers. It’s advisable to shop around and compare prices from different suppliers to ensure the best deal.

When looking for concrete wall ties for sale, there are several factors to consider. Ties come in various materials, including galvanized steel and stainless steel, each with its unique properties. Galvanized ties are often preferred for their corrosion resistance, making them suitable for outdoor applications. Stainless steel ties, while more expensive, offer superior durability and resistance to environmental factors, making them ideal for coastal areas or regions with high humidity.

4. Гибкость Подвесные сетки легко модифицировать. Вы всегда можете добавить новые элементы или изменить конфигурацию в зависимости от изменяющихся потребностей.

When selecting a metal compression spring, several factors must be considered, including load capacity, operating temperature, corrosion resistance, and fatigue life. The choice of material and manufacturing method can significantly impact these characteristics. Additionally, springs are often tested for quality assurance to ensure they meet industry standards and requirements.

Iron mesh wire is an environmentally friendly option in many applications. It is recyclable, and using it can contribute to sustainability efforts in construction and manufacturing. By choosing iron mesh, industries can reduce waste and promote a circular economy.

من الفوائد الأخرى التي يتمتع بها سياج الرابط القصير هو كفاءته في توفير مستوى جيد من الأمان دون أن يبدو مهيبًا أو خانقًا. على عكس بعض أنظمة السياج الأخرى، فإن هذا النوع يتيح رؤية واضحة، مما يجعله خيارًا مثاليًا للحدائق العامة والأماكن الترفيهية.

Welded wire spacers are essential for maintaining the correct spacing between concrete blocks during construction. These spacers, made from durable welded wire, ensure that the blocks are evenly spaced and properly aligned. The uniformity provided by welded wire spacers is crucial for achieving consistent grout or mortar application, which in turn affects the overall structural integrity of the wall. When choosing welded wire spacers, consider factors such as wire thickness, spacing requirements, and the specific needs of your construction project to ensure optimal performance.

Plaster beads are essential elements in the world of construction and interior design, playing a pivotal role in achieving a refined finish and structural integrity in plaster applications. With various types available, it's crucial to understand each type’s features and practical applications. This article delves into the different plaster bead types, highlighting their uses and benefits.

Types of Wall Ties

சில்வர் பூக்களால் உள்ள நெய்வாழ்க்கை மற்றும் அதன் பயன்பாடுகள்

Korzyści wynikające z użycia łączników

Den korrekte dimensionering af en 2 inch coil spring er nødvendigt for at opnå de ønskede præstationer. Hvis en fjeder er for svag, kan den hurtigt blive beskadiget, mens en for stærk fjeder kan gøre det svært at betjene det udstyr, den er installeret i. Derfor er det vigtigt at udføre præcise beregninger og eventuelt simuleringer for at sikre, at designet opfylder kravene.

Väggförbindningar för Stenmurar

En av de største fordelene med å bruke 275% veggrør er deres evne til å forbedre bygningens motstand mot ytre påkjenninger, som vind og jordskjelv. Dette er spesielt viktig i områder som er utsatt for slike krefter, da en stabil struktur kan redde liv og minimere skader på eiendom. Videre kan 275% veggrør bidra til å forlenge bygningens levetid, noe som gir langsiktige kostnadsbesparelser for eiere og utviklere.

275 wall ties

One of the most notable features of black metal mesh sheets is their versatility. In architecture and interior design, they are increasingly being used to create stunning visual effects in modern buildings and homes. These sheets can serve both functional and decorative purposes, acting as partitions, railings, or even artistic wall installations. The use of black metal mesh can add a sense of sophistication and elegance to a space, allowing light to filter through while still providing a degree of privacy.

Agricultural Uses

Floral wire is made from a thin, flexible metal that comes in various gauges, allowing florists the ability to manipulate stems, secure arrangements, and even create intricate designs. When deciding to buy floral wire, it’s essential to consider the gauge that best suits your needs. Generally, lower gauges (less than 20) indicate thicker wire that is robust and perfect for supporting heavier flowers or stabilizing arrangements. Higher gauges, on the other hand, are more flexible and ideal for delicate blooms.

High Stakes for Yard Signs The Power of Public Messaging in Local Elections

2. Improved Durability Constructed from galvanised steel or other corrosion-resistant materials, corrugated brick ties are designed to withstand the elements. Their durability ensures that they can endure moisture, temperature fluctuations, and chemical exposure without compromising their performance, leading to a longer lifespan for the building.

In summary, big compression springs are essential components in numerous industries, playing a pivotal role in the success and safety of various applications. Their ability to absorb shock, support heavy loads, and provide reliable performance makes them indispensable in today’s fast-paced world. As technology continues to evolve, the demand for innovative and efficient spring solutions is expected to grow, solidifying the place of big compression springs in engineering and design. Whether in industrial machinery or everyday household items, the impact of these springs is far-reaching and significant.

. , , . , .

Another factor influencing prices is the wire diameter and mesh size. Welded mesh sheets come in various gauges and mesh openings, which can affect both strength and price. Thicker wires provide greater load-bearing capacity but come at a higher cost. Similarly, dense mesh patterns, which offer more material coverage, will result in increased costs compared to sheets with larger openings. Buyers should consider their specific needs regarding strength and application to determine the most cost-effective option.

weld mesh sheets prices

1. Fencing Materials Various materials are available for cattle fencing. Traditional wooden posts and barbed wire have been popular for years, but they may not be the most efficient in terms of durability and maintenance. High-tensile wire and steel fencing, on the other hand, offer greater strength, often requiring less maintenance and providing a longer lifespan. Electric fencing is another option that is particularly useful for keeping cattle contained; it can be an effective deterrent against straying or trying to push through the barrier.

There are primarily two types of wire mesh used in concrete reinforcement