hot dip galvanized wire manufacturers

Latest articles

hot dip galvanized wire manufacturersSodium and magnesium contain less combustible impurities, and when extinguished, they simply glow. Galvanizing belongs to the electrochemical processing process which is widely used on the surface of steel. So it is, first of all, because zinc coating (especially after supplementary processing, such as chromate treatment and phosphating) resistance to atmosphere and water is more stable, and the galvanized process itself this is cheaper and simple.

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturers

Post time: 05-05-22...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read Morehot dip galvanized wire manufacturers

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read Morehot dip galvanized wire manufacturers

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read Morehot dip galvanized wire manufacturers

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturersThe amount of zinc on the surface of high zinc barbed rope is about 5 times that of general zinc barbed rope, thus greatly prolonging the time of rust resistance. In the appearance of the two products are silver white and metal texture is better, for the distinction between the two products is more difficult to distinguish if it is a layman, but for long-term work of professionals can be separated from the two at a glance.

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturersCustomers do not need to worry about the impact of the production cycle when ordering products from the thorn rope factory, because the overall treatment is now focused on the waste gas, so the production of thorn rope should be said to have the least impact. Customers ordering products in the thorn rope factory can rest assured that the delivery time this piece, can provide customers with goods on time. If the production cycle is not affected, then customers will be more assured of the thorn rope factory.

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturers

Post time: 15-11-22...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturersThe national standard on the use of wire mesh standards have certain requirements, diameter and mesh size matching use, rather than simply diameter size, on the plaster layer to use is mesh should not be greater than 20×20, diameter is not easy to be less than 1mm, light selection diameter is not much significance, choose 40×40×0.9 and choose 10×10×0.6 wire mesh, Which is better, I’m afraid is 10×10×0.6.

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

hot dip galvanized wire manufacturersDuring this process, each time the wire is pulled over, the surface hardens due to the high friction temperature. So basically every time you pull it you have to annealing it in the furnace. On the one hand, it is to reduce the surface hardness. On the other hand, during the process of wire pulling, only the surface is deformed, and the center is unchanged. So there’s a lot of stress inside. Therefore, it is necessary to rely on annealing to eliminate the internal stress, so that the wire becomes soft again to eliminate the stress before being drawn again.

...

hot dip galvanized wire manufacturers 【hot dip galvanized wire manufacturers】

Read More

Popular articles

- Of course, the quality of any kind of product is also affected by the implementation of the specification of the manufacturer, if it is the welding screen manufacturers in the production of their own is not very high implementation of the specification, or in the production line of the procedure specification has declined, or there is no higher requirements on the production link.

Post time: 14-10-22- The cage can be placed in a corner so that the bird can see what is going on around it and can retreat to the back of the cage without fear of being approached. The height of the cage from the ground is also important and is ideal slightly below eye level.

Post time: 08-03-23

Latest articles

-

-

-

-

-

Wire mesh first welding after galvanized is through the end of welding and then the company to produce wire mesh wire mesh steel mesh construction mesh, floor heating mesh galvanized or hot dip galvanized. First galvanized after welding is to change wire mesh, after the end of welding can see the solder joint; The two processes are different in price. The cost of plating after welding is low, the appearance is smooth, and the cost of plating after welding is high, and it is not easy to rust.

-

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

Links

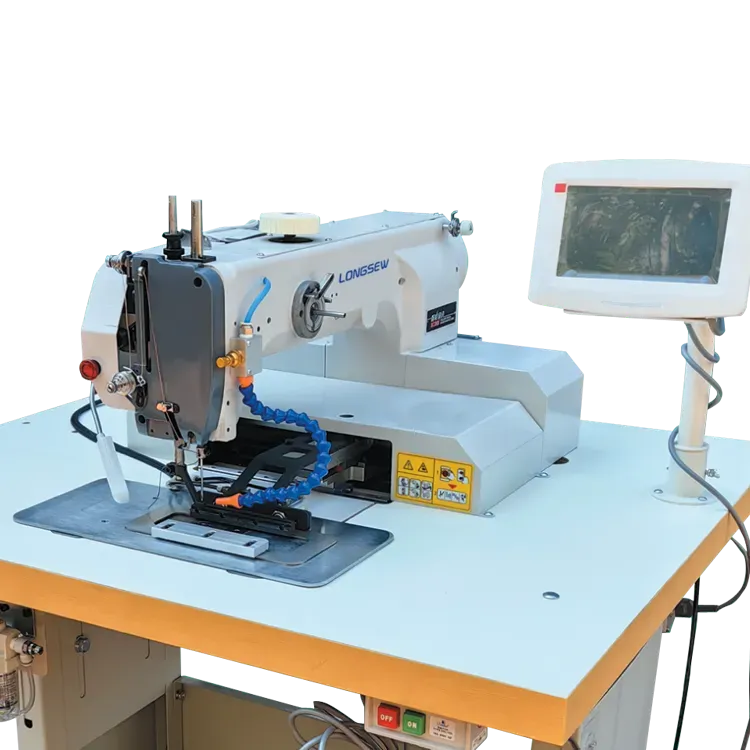

The Dressmaker Zig Zag Sewing Machine stands out for its user-friendly features that cater to both beginners and seasoned sewists. One of its most notable features is the adjustable stitch width and length, enabling users to customize their stitches for specific projects. This feature is particularly beneficial for tasks such as sewing curves or finishing edges, where a zigzag stitch can prevent fraying and provide a professional finish.

Conclusion

The Art and Craft of Quilting Machine Embroidery Designs

Moreover, sturdy sewing machines are generally designed with user comfort in mind. Many models incorporate ergonomic features such as adjustable speed controls, easy-to-use manual dials, and spacious work areas. This focus on comfort allows sewists to work for extended periods without discomfort, ensuring that creativity flows unhindered. Additionally, many sturdy machines offer a wide selection of presser feet, enabling users to execute various techniques, from quilting to embroidery, with utmost precision.

2. Enhanced Durability The reinforced seams created by a double stitch machine provide extra strength, reducing the likelihood of seams unraveling over time. This quality is vital for garments that undergo intensive use, ensuring customer satisfaction and reducing return rates.

Enhanced Creativity and Versatility

Raised bed sewing machines are designed with a unique platform that elevates the sewing area. This elevated structure enables sewists to work with larger pieces of fabric, such as quilts, home decor items, or even clothing, without the constant struggle of wrangling excess material. This is particularly beneficial for those who engage in quilting or crafting larger items where space and ease of handling are crucial. The raised bed design not only eases the physical strain of sewing but also enhances the precision of stitching as it allows for a smoother flow of the fabric.

2. Versatility With a heavy duty motor, a sewing machine can tackle a wide array of materials, from denim to leather to canvas. This versatility makes heavy duty machines suitable for various projects, enabling crafters and manufacturers to diversify their offerings.

gsc367 . They study a variety of genetic disorders, including both rare monogenic disorders and common complex disorders. They learn about the genetic basis of these disorders, how they are diagnosed and treated, and how genetic testing can be used to identify individuals at risk.

Furthermore, as automakers evolve towards sustainable practices, automotive sewing machines have adapted to utilize eco-friendly materials without compromising durability. Innovations such as the use of recycled fabrics and bio-based materials are becoming more prevalent, and the sewing machines that fabricate these materials are at the forefront of this transition.

Automatic bag closer machines are designed to seal bags rapidly and securely, using a variety of methods including heat sealing, stitching, and adhesive sealing. The selection of a sealing method often depends on the type of product being packaged, the material of the bag, and the desired durability of the seal. For instance, in industries dealing with perishable goods such as food and pharmaceuticals, heat sealing is often preferred for its ability to create airtight seals that prolong shelf life.

The Long Arm Heavy Duty Zigzag Sewing Machine A Seamstress's Best Friend

4. Cost-Effectiveness The improved efficiency in filling and discharging operations due to spout rosettes can lead to significant cost savings. By optimizing material flow, companies can reduce the time needed for loading and unloading, leading to better utilization of labor and equipment.

Maintenance Tips

Moreover, with the growing emphasis on sustainable and ethical manufacturing practices, the reliability and efficiency of walking foot machines play a vital role in supporting these efforts. By ensuring efficient use of materials through precise stitching, manufacturers can minimize waste and optimize their resource management. The ability to produce high-quality products that stand the test of time is crucial in a market that increasingly values longevity and sustainability.

- Cutting Measure carefully and cut slowly to ensure precision. Leather can be unforgiving, so take your time.

One of the standout features is its ability to operate at high speeds, allowing manufacturers to keep pace with production demands while maintaining precision. Additionally, the machine features adjustable stitch length settings, enabling operators to customize the cutting process according to the specific fabric types and requirements. Many models also come with a built-in thread trimmer, which significantly enhances productivity by eliminating the need for manual cutting of threads after sewing.

Additionally, the integration of smart technology into automatic sewing machines represents a significant advancement in the garment industry. Many of these machines are now equipped with sensors and software that monitor performance, predict maintenance needs, and even suggest optimal sewing settings based on fabric types. This level of intelligence not only enhances operational efficiency but also reduces downtime, ensuring that manufacturers can keep their production lines running smoothly.

In addition to garment construction, an overlocker can be a valuable tool for quilting and crafting. You can use it to finish quilt edges, making for a neat and tidy appearance. It’s also great for creating soft toys, home décor items, and other craft projects where a polished finish is desirable.

(2) When the heavy material sewing machine is running, the steering of the upper wheel should be counterclockwise (viewed from the outside of the upper wheel).

3. Practice on Samples If you are new to this type of stitching, practice on fabric scraps. This will help you familiarize yourself with the machine's operation and the intricacies of the stitch.

1. Preparing Your Fabric

Conclusion

When tackling thick materials, it’s important to use the right needles and thread. A sewing machine that can accommodate large, robust needles (like a 16 or 18 size) is ideal for heavy fabrics. Similarly, using heavy-duty thread will help prevent breakage and ensure strong seams. Make sure your sewing machine is compatible with such needles and threads.

The Versatile Zigzag Foot Sewing Machine A Seamstress's Best Friend

The Rising Trend of Jumbo Belts

Outerwear Production

At the heart of long arm sewing is the long arm quilting machine, which typically features a large table or frame and a specialized sewing mechanism. Unlike standard sewing machines, long arm machines allow for the movement of the fabric while the sewing head remains stationary, or vice versa, depending on the design. This setup gives users the ability to quilt large quilts without the struggle of maneuvering tons of fabric through the small throat space of a regular machine.

In conclusion, leather sewing machine companies represent a vital link in the craftsmanship and production of leather goods. They combine innovation, sustainability, and community support, ensuring that both new and experienced artisans can create high-quality products. As the demand for leather continues to grow, these companies are not just manufacturers; they are enablers of creativity, helping artisans around the world transform their visions into reality. Whether it's a custom leather handbag or a pair of finely crafted shoes, the journey of creation often begins with the right sewing machine, making these companies an indispensable part of the leather goods industry.

1. Heavy-Duty Construction Upholstery fabrics are often thick and robust, such as canvas, denim, or leather. Seeking a sewing machine made with durable materials will ensure it can handle the stress of heavy fabrics without breaking or malfunctioning.

The precision zigzag sewing machine can be utilized in countless projects. For garment construction, the zigzag stitch is perfect for finishing seams on knit fabrics, preventing fraying while allowing for fabric stretch. In quilting, the machine’s ability to create decorative stitches adds unique flair to quilt blocks. Additionally, crafty individuals can leverage the machine for embellishing accessories, ensuring that every project reflects their unique style.

Key Features to Look For

5. Take Your Time Patience is key. Taking your time while sewing will enhance the quality of your work and ensure that each seam is neatly finished.

Automatic template sewing machines are designed to automate various sewing tasks, reducing the need for manual intervention. Unlike traditional sewing machines that require constant adjustments and oversight, these advanced machines use pre-programmed templates to execute intricate patterns and designs with precision. This automation allows for consistent quality across multiple pieces, which is particularly beneficial for mass production environments.

4. Budget Determine your budget before starting your search. Prices can vary significantly based on the machine's capabilities and brand. It's crucial to balance cost with the features you need to ensure you're getting the right machine for your business.