galvanised wire for climbing plants

Latest articles

galvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read More

galvanised wire for climbing plants

Post time: 26-05-23...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read More1. Put the cat carefully in the special basin for washing the cat. Keep your cat as calm as possible.

galvanised wire for climbing plants...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read Moregalvanised wire for climbing plants

...

galvanised wire for climbing plants 【galvanised wire for climbing plants】

Read More

Popular articles

- (2) The construction is simple and does not need special technology;

- Galvanized iron wire is divided into hot galvanized wire and cold galvanized wire, using low carbon steel wire processing, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. It has good toughness and elasticity, and the amount of zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Galvanized iron wire can be cut off in the construction of the tie wire, the length of 20cm, 30cm and 40cm, can be cut off according to requirements.

2, reduce the bivalent iron ion in the plating aid used for hot plating wire, reduce the formation of zinc slag

- 3. Gently rub soapy water on its body and scrub gently with a towel. Make sure you don’t get anything in his eyes or it might scare him into attacking you (he might show his little fangs and claws).

- Although to be able to reduce the cost of production, but the overall strength of the product will have a great lack, so in this case will also let it have a great strength drop. Of course, in the mall, the higher the intensity of the data in the production of the higher the implementation of norms, naturally there will be certain progress in the price.

Latest articles

-

-

-

Post time: 15-11-22 -

Stainless steel barbed rope in the way of corrosion is not very, because the surface is not treated but rely on its own raw materials for corrosion resistance, so there will be no chemical reaction.

-

The basic thing to choose a pet carrier is to be able to stand up straight inside it, so that your pet can be comfortable, but also need to be able to stretch out all four feet when lying down. Think of your pet as a person, and give it a larger cage where it can move around on one side and sleep on the other. You can use an old blanket for cushions in your pet’s cage, or buy special cushions for pets, as long as they are comfortable.

-

Replace the column that corroded or misinterpreted and so on resulting in the loss of effect, place the replacement area together from the beginning, and reinforce the column with unstable pile foundation in time. The second is about the protection of galvanized barbed rope itself, to repair the damaged local, will be severely replaced by rust.

Links

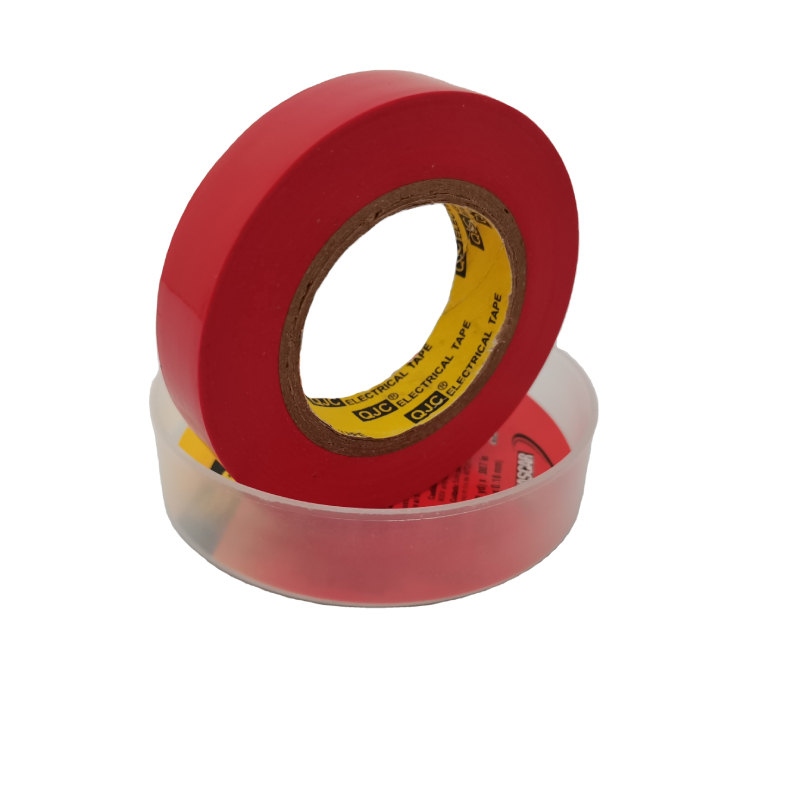

Applications of PVC Electrical Insulation Tape

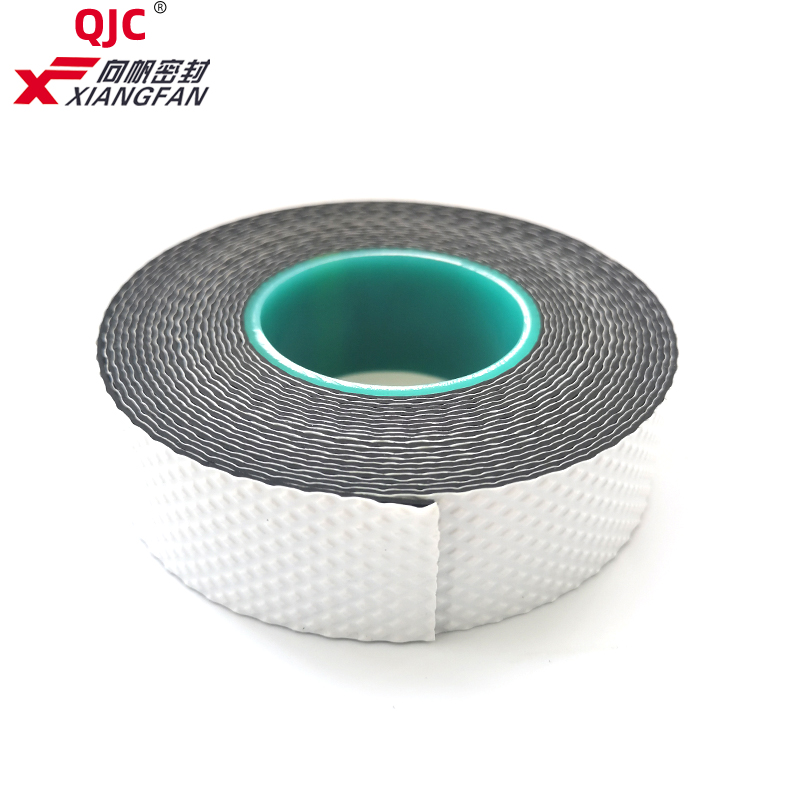

- Semi-Conductive Water Blocking Tape A Comprehensive Guide

- Red and White Floor Marking Tape A Crucial Tool in Workplace Organization

- The Unmatched Power of Flex Tape A Clear, Waterproof Solution

4. Press the tape firmly against the surface to ensure full contact between the tape and the substrate.Smooth out any wrinkles, bubbles, or gaps to create a tight seal. In some cases, you might need to apply multiple layers of tape, particularly when sealing larger gaps or joints.

CODE COMPLIANCE

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.

sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.1. Warehouses In a bustling warehouse, where machinery, personnel, and products interact, clear pathways are essential. Red and white tape can demarcate pedestrian walkways, separate moving zones, or highlight dangerous areas, such as near forklifts.

The processing unit is the component that allows you to feed commands into your control box and monitor its performance or status. Most control boxes utilize microcontrollers or PLCs, which are capable of fulfilling complex functions. For instance, they can interpret your predefined algorithms and command your system to execute them.

1. Enhanced Fire Safety The most apparent benefit of fireproof gasket tape is its ability to resist flames and high temperatures. By utilizing this tape, businesses can significantly lower the risk of fire hazards in operational spaces. When applied correctly, fireproof gasket tape helps to create a barrier against the spread of fire, protecting equipment and personnel.

fireproof gasket tape

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion.

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion.1. Waterproofing Capabilities One of the primary advantages of butyl rubber roofing sheets is their exceptional waterproofing ability. Their impermeable nature prevents water seepage, which is critical for protecting structures from moisture-related damages. This quality makes butyl rubber roofing sheets particularly suitable for low-slope roofs, where water accumulation can be a concern.

In the realm of adhesive materials, PVC black tape stands out for its exceptional versatility and reliability. This specialized tape, made from polyvinyl chloride (PVC), is predominantly black in color, making it an aesthetically pleasing option for various applications. It is a staple in many industries, including electrical, construction, automotive, and arts and crafts, due to its unique properties and benefits.

Rubber tape usually does not have an adhesive side but sticks to itself. This means it has to be stretched entirely around a cable to effectively adhere to itself using elastic tension against the backing.

One of the most impressive demonstrations of Flex Tape's strength is its ability to hold heavy objects in place. Whether it's a broken chair, a loose shelf, or a damaged car bumper, Flex Tape can be used to provide a temporary fix until a more permanent solution can be found.

Moisture Control

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

In addition to safety, fire-resistant electrical tape can increase the longevity of electrical connections. Regular electrical tape may degrade over time, especially under extreme conditions, leading to insulation failures. The durability of fire-resistant tape means it can withstand harsher conditions, thereby extending the lifespan of electrical installations.