Material Choices and Construction

high speed splicing tape. Its strong adhesive properties ensure that spliced materials stay securely bonded together, even under extreme stress or tension. This makes high-speed splicing tape an ideal solution for industries that require reliable and long-lasting splices, such as the packaging and printing industries.

Length: Available in 5m and 10m

The key feature of amalgamating rubber tape is its ability to effectively bond to itself when stretched and wrapped around an object. This self-amalgamating characteristic creates a strong and durable seal that is resistant to water, chemicals, UV rays, and extreme temperatures. As a result, this tape is widely used for electrical insulation, plumbing repairs, cable management, and automotive applications.

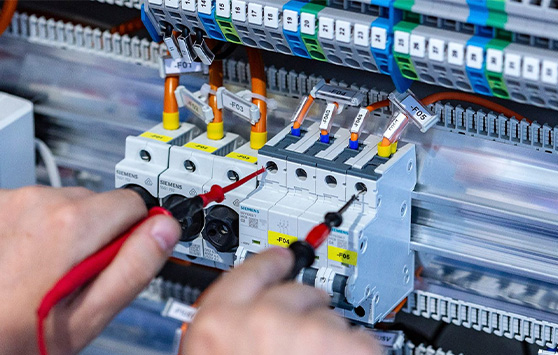

4. Electrical Insulation The tape provides excellent electrical insulation properties, with a dielectric strength that prevents electrical leakage. This characteristic is crucial for maintaining safety in electrical systems.

Temperature Rating: 90°C

The Importance of Fire Seal Tape in Safety and Construction

One of the significant advantages of using fireproof gasket tape is its versatility. It can be employed in various applications, including but not limited to sealing joints in HVAC systems, creating airtight seals in exhaust systems, and providing insulation in electrical enclosures. The tape can also be used in industries dealing with flammable materials, where it plays a crucial role in enhancing the safety of the work environment.

3. Peel and stick.Butyl sealant tape usually comes with a protective backing to prevent it from sticking to itself during storage and handling. Carefully peel off the backing to expose the adhesive side of the tape. Position the adhesive side of the tape on the surface, and carefully align it with the area to be sealed.

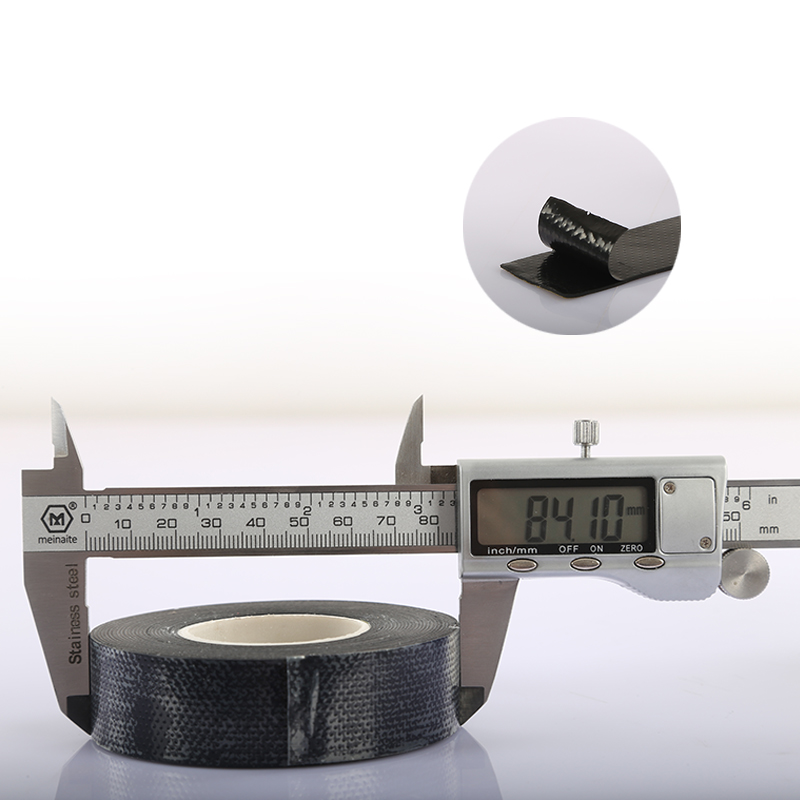

Just from looking at the roll, it is very hard to tell what type of rubber is used on the tape. Look at the figure to the right, and this same picture can be used to describe every type of rubber-tape below. The key is to ask the supplier what type of rubber adhesive is used. Like acrylics, rubber adhesives can be divided into two subgroups: Natural and Synthetic

Just from looking at the roll, it is very hard to tell what type of rubber is used on the tape. Look at the figure to the right, and this same picture can be used to describe every type of rubber-tape below. The key is to ask the supplier what type of rubber adhesive is used. Like acrylics, rubber adhesives can be divided into two subgroups: Natural and Synthetic