wire mesh screen factory

Latest articles

wire mesh screen factory

...

wire mesh screen factory 【wire mesh screen factory】

Read More

wire mesh screen factory

Post time: 17-04-23...

wire mesh screen factory 【wire mesh screen factory】

Read Morewire mesh screen factory

...

wire mesh screen factory 【wire mesh screen factory】

Read More

wire mesh screen factoryHexagon mesh weight calculation method is: hexagon mesh weight calculation method: wire.× wire.× base x length x width ÷2=kg base: 1/2′=2.151′=1.273/4′=1.65/8′=1.875/4′=1.091′x1/2′ : 3′=0.4 warp.× Warp.×2x length x width ÷8×3=kg

...

wire mesh screen factory 【wire mesh screen factory】

Read MoreThe middle of the two thorns is 7 to 8 circles, while the ordinary thorn rope is only 3 and a half circles, showing neat and beautiful.

wire mesh screen factory...

wire mesh screen factory 【wire mesh screen factory】

Read MoreIn this temperature range, the zinc solution is severely corroded to the workpiece and the zinc pot, and the iron is lost at 560 degrees Celsius to add obviously, and the zinc will be the iron substrate above 660 degrees Celsius, zinc slag will be added quickly, plating cannot be used. Therefore, electroplating is carried out in the range of 430~450 degrees Celsius.

wire mesh screen factory...

wire mesh screen factory 【wire mesh screen factory】

Read More

wire mesh screen factory

Post time: 16-12-22...

wire mesh screen factory 【wire mesh screen factory】

Read Morewire mesh screen factory

...

wire mesh screen factory 【wire mesh screen factory】

Read Morewire mesh screen factory

...

wire mesh screen factory 【wire mesh screen factory】

Read More(1) Protect and support seawalls, hillsides, roads and Bridges, river courses and other water conservancy projects;

wire mesh screen factory...

wire mesh screen factory 【wire mesh screen factory】

Read More

Popular articles

1, stress relief before plating where the maximum tensile strength is greater than 1034Mpa key and important parts before plating should be at 200±10℃ stress relief for more than 1 hours, carburizing or surface quenching parts should be at 140±10℃ stress relief for more than 5 hours.

The appearance quality of cold-drawn low carbon steel wire in each inspection lot shall be all visually inspected. The appearance of steel wire shall not have cracks, burrs, corrosion and mechanical damage affecting mechanical function. Cold-drawn low carbon steel wire with unqualified appearance can be used in engineering after treatment and inspection.

Appellation: Hook fence is a variety of guardrail. The diameter of the opposite side of each mesh is generally 6.5cm-14cm. The thickness of the wire used is generally from 3.5mm to 6mm. Wire material is generally Q235 low carbon wire. The wire is welded by gimmick into decorative hook mesh black. The general size of the net is 1.5 meters X4 meters, 2 meters X4 meters, 2 meters X3 meters. The general surface treatment is cold (electric) galvanized treatment. There are also hot dip galvanizing, dip plastic, spray plastic. But overall, 99 percent is cold (electric) galvanized.

- Of course, the quality of any kind of product is also affected by the implementation of the specification by the manufacturer. If the manufacturer of electric welding mesh has no high implementation specification in the production itself, or the procedure specification has declined in the production line, or there is no higher requirement on the production link.

Latest articles

Links

Whether you're looking to enhance the security of your property, add a touch of elegance to your outdoor space, or create a unique focal point for your home or business, Orion Ornamental Iron Inc. has the expertise and resources to bring your vision to life.

- Secondly, the design intricacy significantly affects the price. A simple, straight-edged fence will cost less than one with elaborate scrolls, patterns, or custom designs. Each additional detail requires more time, labor, and skill from the fabricator, thereby increasing the price.

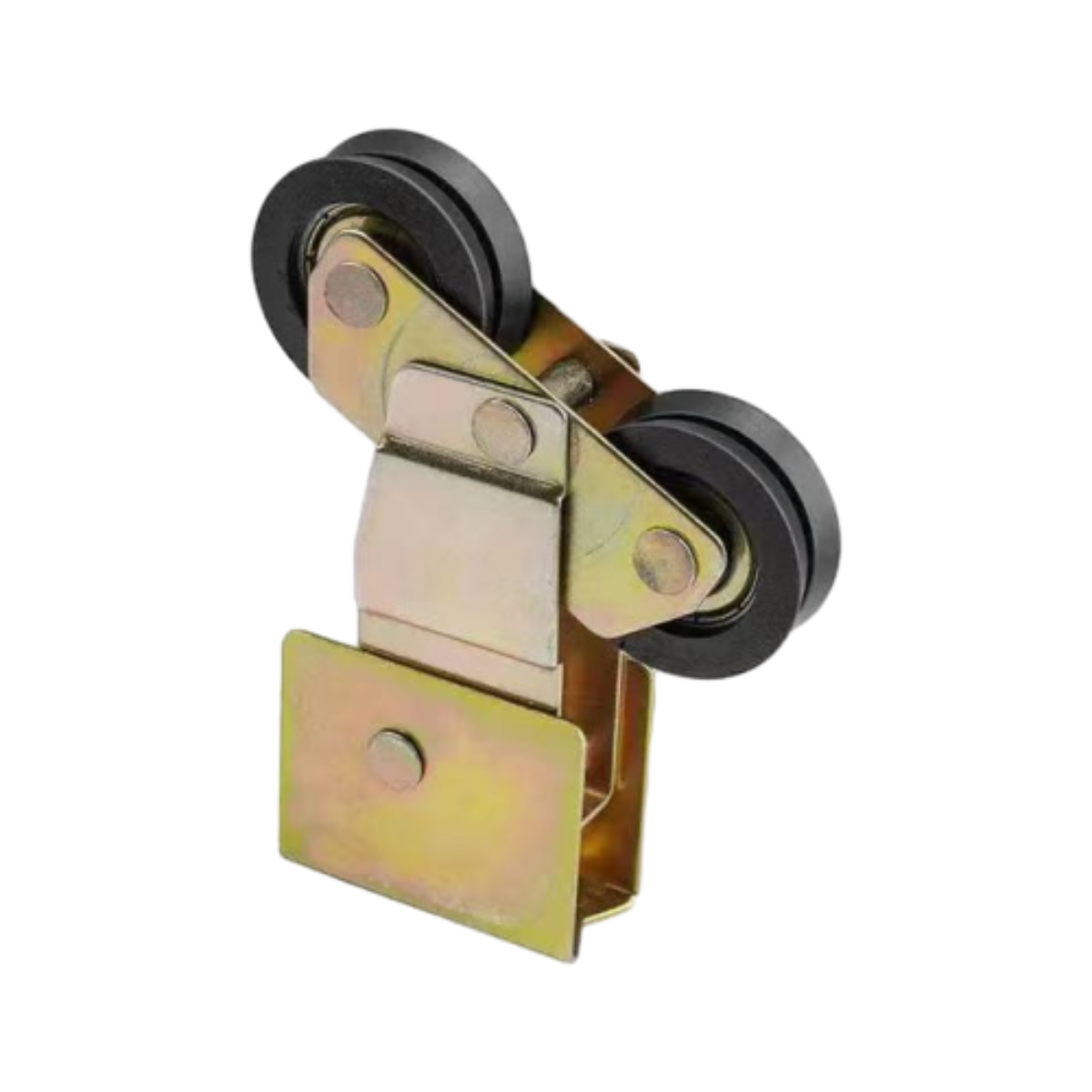

- The design of aluminium window rollers is a testament to modern engineering. With precision engineering, these rollers ensure a smooth gliding action, allowing windows to open and close effortlessly. This not only enhances user convenience but also contributes to energy efficiency by facilitating proper ventilation. The sleek and slender profile of aluminium rollers complements the clean lines of aluminium windows, adding to the overall aesthetic appeal of the building.

Aluminum Fencing

Most of these features, which used to be unique to iron, are now available in steel, which is by a large margin the superior material. And visually, the only difference between the two is the texture. Steel is smooth, while iron has a visible grain, whether it is produced by casting, or by pulling. This grain is actually caused by impurities in the iron and is what accounts for its unreliable nature. These impurities cause weak points in the iron that can lead to breakage when it’s put under stress. Steel’s smooth appearance results from the fact that these impurities have been burned out, or, in the case of carbon, evenly distributed throughout the material. When you think of the medieval blacksmith hammering away, what he is doing is distributing the carbon evenly to turn iron into steel.