portable quail cage

Latest articles

portable quail cageCompared with electric galvanized iron wire, hot dip galvanized iron wire has higher zinc layer, better anti-corrosion performance, and is suitable for the more important anti-corrosion and anti-rust status.

...

portable quail cage 【portable quail cage】

Read More

portable quail cage3. Acid activation acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts, without excessive corrosion on the matrix.

...

portable quail cage 【portable quail cage】

Read More

portable quail cageDecorative hook mesh selection of stainless steel, aluminum alloy, brass, copper and other alloy materials, through the special process of preparation of hook mesh. It is a silk screen made of decoration. Today we introduce the aperture and wire diameter of the decorative hook mesh.

...

portable quail cage 【portable quail cage】

Read MoreThe middle of the two thorns is 7 to 8 circles, while the ordinary thorn rope is only 3 and a half circles, showing neat and beautiful.

portable quail cage...

portable quail cage 【portable quail cage】

Read More

portable quail cageTwo, the production process is different

...

portable quail cage 【portable quail cage】

Read Moreportable quail cage

...

portable quail cage 【portable quail cage】

Read Moreportable quail cage

...

portable quail cage 【portable quail cage】

Read More

portable quail cageIn general, the cost of hot dipping zinc is lower than that of other maintenance coatings. The reason is very simple. Other maintenance coatings, such as sand painting, are labor-intensive processes, whereas hot dipping zinc processes are highly mechanized and tightly controlled in-plant construction. Hot dip zinc coating can be visually and briefly tested for non-destructive coating thickness.

...

portable quail cage 【portable quail cage】

Read Moreportable quail cage

...

portable quail cage 【portable quail cage】

Read MorePet cage has many types, and selective is bigger, pet cages are generally made of wire, with better coarse, then at the bottom with a wheel base, such a simple pet basket was made, in the wheel at the bottom of the mount is for the convenience of the mobile, a pet cages should also adapt to the location of the production in addition to a door, Convenient in pet feeding when more convenient.

portable quail cage...

portable quail cage 【portable quail cage】

Read More

Popular articles

- Cold galvanized is in the plating tank through the current unidirectional zinc gradually plated on the metal surface, the production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, poor corrosion resistance, generally a few months will rust. With the rapid development of market economy, all walks of life are improving the production process and quality of products, galvanized iron wire industry is of course no exception. But because of the variety of galvanized iron wire, its characteristics and production technology are not the same.

- Relatively speaking, the wire is relatively soft, suitable for binding. Disadvantages are low hardness, low tension, easy to stretch, not suitable for building materials. In different applicable environment, we should make a reasonable choice. So in the usual use of cold drawing wire and wire, according to their own needs to choose, although the length of the same, but the performance is not the same.

Post time: 11-06-24

Latest articles

-

-

“At present, many international well-known pet manufacturers have also seized the huge business opportunities of the pet economy, and they continue to develop high-tech pet products, which are favored by consumers.” China’s pet industry should constantly introduce new varieties, strengthen research and development of pet food and supplies, and improve the content of science and technology to win a place in the market competition, an industry insider said.

-

One is to do a good job of galvanized wire packaging, avoid bumping, to ensure the integrity of the zinc layer;

-

-

Generally larger birds choose tall but more dense cage, so as not to damage the tail feathers. Although bailing and other small body, but high flying singing habits, with a special high cage.

-

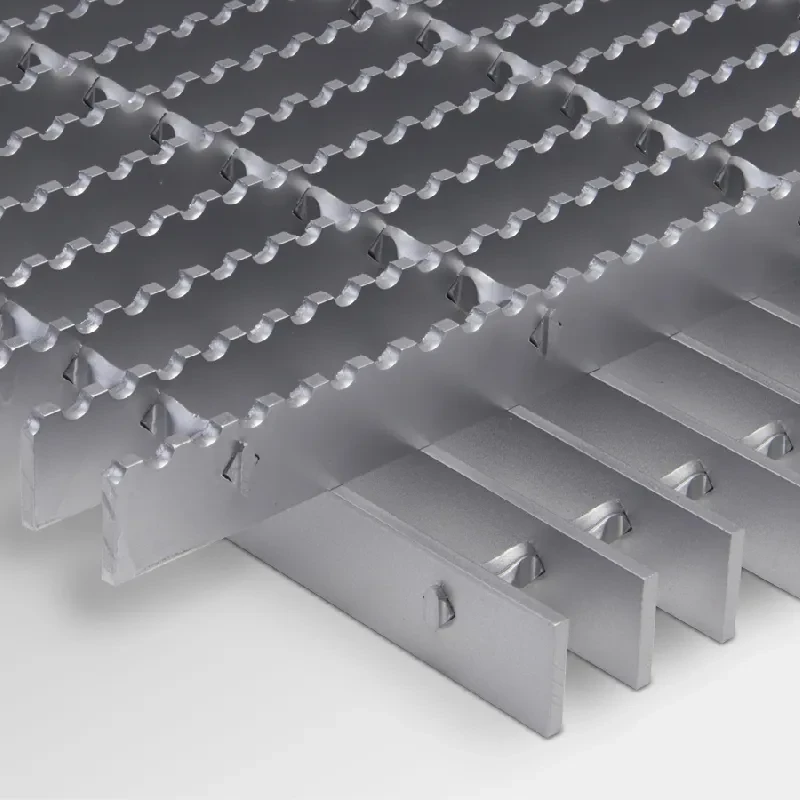

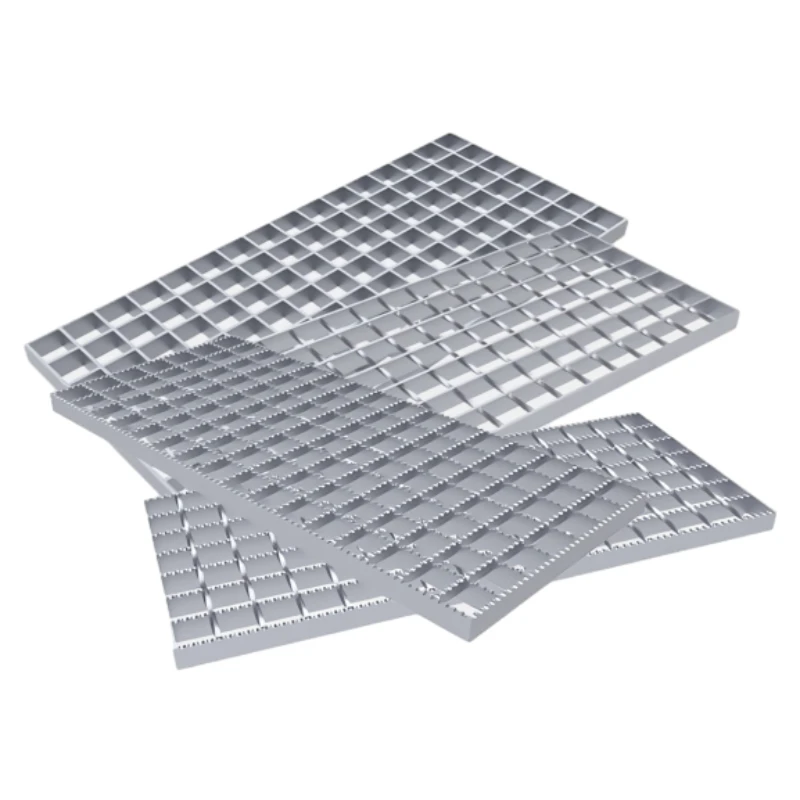

Galvanised steel grating is a versatile and durable material widely used in various industrial and commercial applications. This type of grating is made from steel bars that are welded together to form a grid-like pattern, providing a strong and lightweight structure. The galvanisation process involves coating the steel with a layer of zinc to protect it from corrosion, which significantly enhances its longevity and performance, especially in harsh environments.

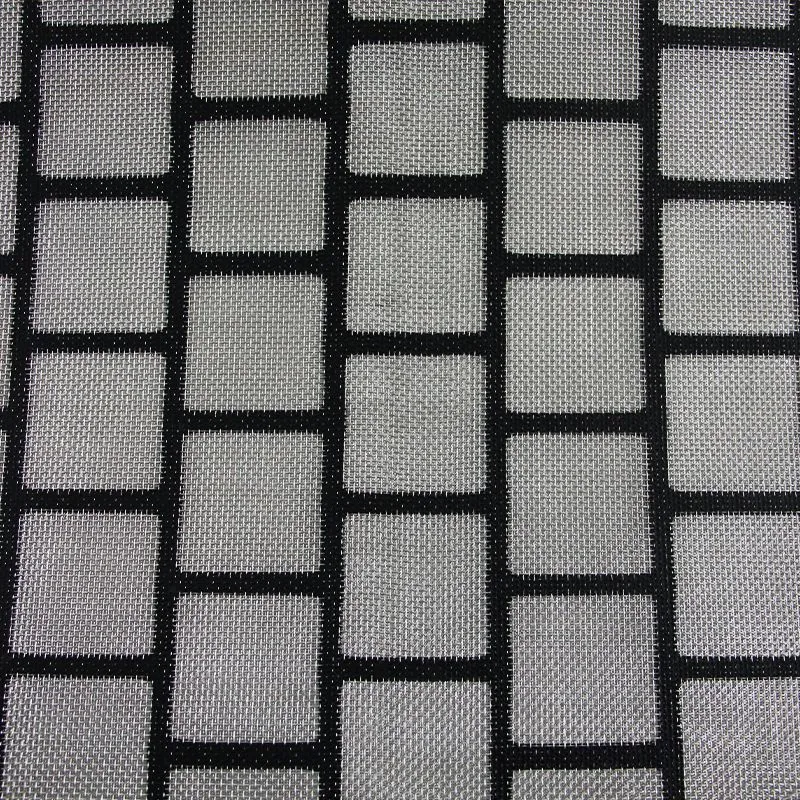

While the oil and gas industry is the primary focus of shale shaker screen mesh applications, its versatility has led to its adoption in other sectors where similar separation and filtration processes are required.

Galvanized grating is typically made from steel that has undergone a galvanization process, which involves coating the metal with zinc to prevent rust and corrosion. The primary types of galvanized grating include welded, pressed, and swage-lock grating, each offering different benefits and applications depending on the load requirements and environment.

- Соҳаҳои саноатӣ Ҳангоми сохтани иншоот, тағйирот ва иваз кардани муколаҳои муосир бо пешниҳоди маводҳои дуруст, ба ҷойи конструктсияи хурсанде, ғалванизатсияшудаи оҳан ҳамчун имконият меравад.

Dans le domaine de la gestion des eaux pluviales, la grille de drainage de tranchée à 4% se révèle être une solution efficace pour assurer l’évacuation des eaux tout en préservant l’intégrité des paysages urbains et ruraux. Cette méthode de drainage, qui repose sur une inclinaison de 4%, permet de diriger l’eau vers les systèmes de collecte de manière optimale et d’éviter les accumulations qui peuvent causer des dommages.

The primary function of shale shaker screen is to facilitate the removal of unwanted solids, such as cuttings and formation debris, from the drilling fluid. This process is crucial for maintaining the quality of the drilling fluid, which directly impacts the efficiency and cost-effectiveness of the drilling operation.