chicken wire screen

Latest articles

chicken wire screenSome customers pay more attention to the quality problem, so they pay more attention to the service life. The barbed rope factory will generally recommend the use of high zinc barbed rope or stainless steel barbed rope.

...

chicken wire screen 【chicken wire screen】

Read Morechicken wire screen

...

chicken wire screen 【chicken wire screen】

Read More(2) can be used as breeding net, sheep net, cattle net, chicken and duck, isolation chicken and duck house, play the role of poultry protection;

chicken wire screen...

chicken wire screen 【chicken wire screen】

Read MoreD, coating adhesion; The zinc layer of the plating parts should be firmly combined with the base metal with sufficient adhesion strength, and will not fall off or bulge after the hammer test.

chicken wire screen...

chicken wire screen 【chicken wire screen】

Read MoreNational standards on the use of wire mesh standards have certain requirements, diameter and mesh size matching use, rather than simply diameter size, on the plaster layer to use is mesh should not be greater than 20×20, diameter is not easy to be less than 1mm, light selection diameter is not much significance, choose 40×40×0.9 and choose 10×10×0.6 wire mesh, Which one is better? 10×10×0.6, I’m afraid.

chicken wire screen...

chicken wire screen 【chicken wire screen】

Read MoreThe strength of the hook net should be satisfactory: when the vehicle is traveling at 80 km/h, the hook net will not fall into the river when it bumps against the railings at a 15 degree Angle. The shape and color of the hook mesh should be in harmony with the surrounding natural environment. The phenomenon planning of important Bridges should be done well.

chicken wire screen...

chicken wire screen 【chicken wire screen】

Read Morechicken wire screen

...

chicken wire screen 【chicken wire screen】

Read Morechicken wire screen

...

chicken wire screen 【chicken wire screen】

Read Morechicken wire screen

...

chicken wire screen 【chicken wire screen】

Read More

chicken wire screenFirst, galvanizing can enhance the corrosion resistance of the product. Zinc has high potential and excellent anodic protection. When the surface of the product is galvanized, zinc will have an electrochemical reaction with oxygen and water in the environment, thereby forming a dense zinc oxide protective film, preventing the metal from further contact with external oxygen, water and other substances, slowing the corrosion rate of the metal. Galvanized products after wire drawing processing, because the surface of the product has a more dense zinc oxide protective film, it can better resist external corrosion and improve the corrosion resistance of the product.

...

chicken wire screen 【chicken wire screen】

Read More

Popular articles

- (4) Stop the use of more than two strands of galvanized iron wire around the operation method.

- Technical product wire, choose a wire special processing, no broken end, zinc amount uniform bright, general quotation slightly expensive. Galvanized silk also contains sprinkling: one plate per volume weight of about 100kg-1000 kg, mainly suitable for industry, agriculture, animal husbandry. Strong corrosion ability, solid coating and other characteristics.

Post time: 30-05-23

Latest articles

-

-

Bird food, now raising birds can be fed with bird food on the market, which is more convenient, of course, you can also feed some cereals, herbs and so on, in order to supplement nutrition.

-

In summary, as a commonly used anticorrosive material, electrogalvanized wire has good corrosion resistance. Its corrosion resistance mainly depends on the thickness, uniformity and structure of zinc layer, substrate material and environmental conditions and other factors. Through reasonable electroplating process and material selection, the corrosion resistance of electrogalvanized wire can be improved and its service life can be extended.

-

-

Galvanized hexagonal mesh weaving process: double stranded hexagonal mesh, can be divided into three screws and five screws.

-

Post time: 19-04-23

Links

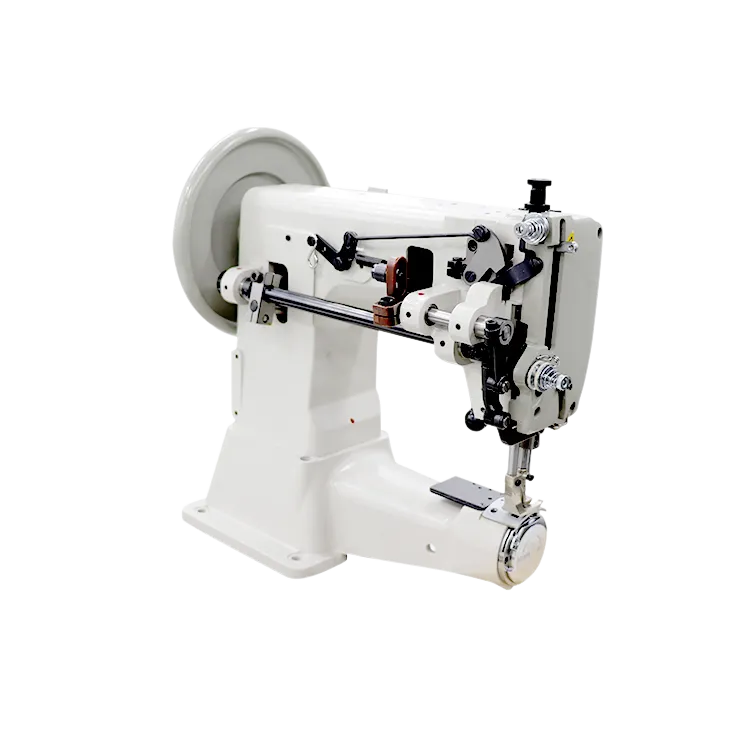

Cylinder arm sewing machines are a staple in many sewing and textile production environments due to their unique design and functionality. Understanding what a cylinder arm sewing machine is used for can help you appreciate its versatility and decide if it’s the right addition to your sewing toolkit. This article will delve into the various applications of cylinder arm sewing machines and highlight their benefits.

Budget is another important factor. While high-end models can be quite an investment, there are also more affordable options that provide great value without compromising on essential features.

What is a Heavy Duty Basic Sewing Machine?

Additionally, a higher sewing speed can help you finish your projects quicker and more efficiently Additionally, a higher sewing speed can help you finish your projects quicker and more efficiently

Additionally, a higher sewing speed can help you finish your projects quicker and more efficiently Additionally, a higher sewing speed can help you finish your projects quicker and more efficiently