electro welded mesh

Latest articles

electro welded mesh

...

electro welded mesh 【electro welded mesh】

Read Moreelectro welded mesh

...

electro welded mesh 【electro welded mesh】

Read Moreelectro welded mesh

...

electro welded mesh 【electro welded mesh】

Read More2.25*2.25mm 10 meters per kilogram

electro welded mesh...

electro welded mesh 【electro welded mesh】

Read More

electro welded meshPet cage is generally made of high quality iron wire, low carbon steel wire, stainless steel wire welding, its characteristics are beautiful, light, folding, easy to store. Pet cage surface treatment is generally: cold galvanizing, hot galvanizing, spraying, dipping, chrome plating, nickel plating and other methods. Pet cage is mainly used for family breeding pets and protection. Tianfu metal products company specializes in the production of various specifications of pet cage such as pigeon cage, dog cage, bird cage, parrot cage and so on.

...

electro welded mesh 【electro welded mesh】

Read More

electro welded meshHot dip galvanizing is a kind of external treatment technology in the production of fasteners. The common varieties of hot dip galvanizing fasteners are electric galvanizing, powder galvanizing, mechanical galvanizing and hot dip galvanizing. Wire factory according to different requirements of customers for fasteners, different hot-dip galvanized surface treatment. Galvanized layer and steel is a metallurgical connection, become a part of the steel surface, so the durability of the coating is more reliable.

...

electro welded mesh 【electro welded mesh】

Read More

electro welded meshContinuous production does not need heating, but needs cooling. Cooling can be in the groove side row thin wall plastic pipe, through the flow of tap water cooling, can also be used as a titanium pipe temperature control device. In the process of composite electroplating galvanized wire, the plating solution must be stirred to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc.

...

electro welded mesh 【electro welded mesh】

Read More

electro welded meshAlthough galvanized iron wire has the protection of galvanized layer, it does not say that it will not rust at all, but delays the time of rust. In general, cold galvanized iron wire can be kept for 1-2 years without rust, hot galvanized iron wire can be used for 8-10 years without rust. If properly maintained, the use time will be longer. So how to prevent galvanized iron wire rust?

...

electro welded mesh 【electro welded mesh】

Read More

electro welded mesh

Post time: 15-11-22...

electro welded mesh 【electro welded mesh】

Read More

electro welded meshThere is also a scaly or boride film or oxide. To remove the photosynovium or oxide commonly used methods are: lead grease removal method, acoustic cleaning method, alkali washing or pickling electrolysis grease to oxide method, these methods in the use of gas or steam harmful to human body, pollution, not environmental protection.

...

electro welded mesh 【electro welded mesh】

Read More

Popular articles

- Cages are more often used for large dogs, which have a lot of strength. The crate must be strong, or the dog will easily break out of the crate.

- Twisting hexagon mesh production factory is the selection of low carbon steel silk woven, mesh structure he has corrosion resistance, high strength and ductility and so on. The diameter of steel wire can reach 2.0mm-4.0mm. The surface of steel wire is usually used for hot-dip galvanized maintenance. The thickness of galvanized maintenance layer can be made according to the needs of customers.

- The common barbed rope produced by the manufacturer is the 14*14 type of barbed rope product. Since the warp wire used is the same as the wire diameter of the barbed rope, it is easier to calculate the length and weight. Usually each kilogram of barbed rope can reach about 10 meters of service length. The length of each kilogram of raw material is about 35 meters. Since 35 meters of raw material wire diameter can produce 10 lengths of barbed rope cost.

- Packaging and binding electric galvanized wire is in the state of liquid zinc, after messy physical and chemical effects, not only on the steel plating thicker pure zinc layer, and also generate a zinc – iron alloy layer. This plating method not only has the corrosion resistance characteristics of galvanized wire, but also has a zinc-iron alloy layer. It also has strong corrosion resistance that can not be compared with galvanizing. Therefore, this plating method is especially suitable for all kinds of strong acid, alkali fog and other strong corrosion environment.

Steel wire after galvanized treatment, the surface will be covered with a layer of zinc metal, to play the role of anti-corrosion, anti-fouling, enhance strength and beauty. The galvanized wire drawing treatment is to process the steel wire by stretching method to obtain a finer, higher strength and smoother surface, and improve its mechanical properties. However, will wire drawing affect the electrical conductivity of galvanized steel wire?

Dogs of all ages seem to love to touch their noses with humans and other animals. In fact, dogs touch their noses as a way of socializing, just like humans shake hands and hug when they meet. But dogs don’t touch every human or every animal. They pick and choose who to touch. If they don’t like you or don’t know you at all, they won’t touch your nose. However, adult dogs will touch almost every puppy’s nose, and they will not only touch the puppy’s nose, but also smell it.

Latest articles

Links

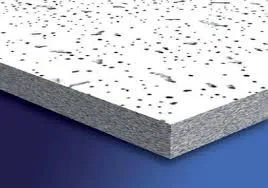

Cross T ceiling grids are widely used in various commercial and residential environments. In commercial settings, they are commonly found in offices, shopping centers, schools, and hospitals. Their ability to accommodate lighting fixtures, air vents, and other utilities makes them particularly suitable for environments requiring a functional, multi-use space.

Thermal Insulation

The R-Value of Mineral Wool Board

5. Cost-Effective Compared to traditional construction materials, laminated gypsum board is generally more affordable. Its ease of installation also reduces labor costs, making it a cost-effective alternative.

The Importance of an Attic Ceiling Hatch A Gateway to Storage and Efficiency

A suspended ceiling consists of a grid framework suspended from the overhead structure, with tiles or panels inserted into the grid. This system allows for easy access to plumbing, electrical wiring, and mechanical systems hidden above the ceiling. The grid is typically made from metal and is designed to support a variety of ceiling tiles, which can range from basic acoustical tiles to more decorative options.

When disposed of at the end of its life cycle, rigid mineral wool board is inert and does not release harmful substances, making it a safe choice for the environment.

Ceiling access panels are essential components in many construction projects, both residential and commercial. They provide access to critical areas such as electrical wiring, plumbing, and HVAC systems that are typically hidden behind ceilings. By having readily accessible access points, maintenance and repairs can be conducted efficiently without the need for extensive demolition or invasive procedures. This article outlines the standard sizes of ceiling access panels, their importance, and considerations during installation.

In recent years, the world of interior design has seen a surge in innovative approaches to ceiling treatments. One such trend that has garnered attention is the use of black ceiling tile grids. This bold design choice not only challenges traditional notions of ceiling aesthetics but also offers a plethora of benefits that enhance the overall ambiance of spaces, particularly in contemporary residential and commercial environments.

Aesthetics play a crucial role in interior design, and gypsum board PVC laminated ceiling panels excel in this regard. They offer a sleek and modern look that can enhance the visual appeal of any space. The variety of designs, colors, and finishes available means that these panels can be tailored to suit different themes, from contemporary to classic. The smooth, glossy finish of PVC adds a touch of elegance, reflecting light to create a sense of spaciousness and brightness in a room.

Choosing the right size for a ceiling access panel is crucial for functionality, maintenance, and aesthetics. By understanding the standard sizes, considering custom options, and evaluating the needs of your particular project, you can select the appropriate access panel that not only meets the practical requirements but also contributes to the overall functionality and appearance of the space. Proper planning and thoughtful consideration will ensure that the access panels serve their intended purpose efficiently and effectively for years to come.

In addition to functionality, safety is a primary consideration when selecting ceiling hatch covers. Building codes often require that access points meet specific standards to ensure the safety of maintenance personnel. High-quality ceiling hatch covers are built to ensure they can support weight and resist damages, presenting a safe access point.

In modern architecture and construction, every detail matters, and this is especially true when it comes to accessibility and functionality. One often overlooked yet vital component is the metal ceiling access hatch. These hatches serve significant purposes in both residential and commercial buildings, offering access to ceiling spaces, utility systems, and even maintenance areas while ensuring the integrity of the ceiling design.

3. Metal Tiles

Conclusion

Understanding Ceiling Access Panels

- Installation Type Ceiling inspection panels can be flush-mounted, surface-mounted, or hinged. The choice depends on the installation requirements and aesthetic considerations.

Importance of Access Panels

Fiber Reinforced Polymer is a composite material that combines a polymer matrix with fiber reinforcements, typically glass or carbon fibers. This combination creates a material that is not only lightweight but also exhibits outstanding strength, corrosion resistance, and durability. These properties make FRP an ideal choice for various applications, including ceiling grids, where structural integrity and aesthetic appeal are paramount.

Suspended ceilings, also known as drop ceilings or false ceilings, are a popular architectural feature in commercial and residential spaces alike. They serve several purposes, from providing a smooth and aesthetically pleasing overhead surface to concealing unsightly wiring, ductwork, and plumbing. One of the key components of a suspended ceiling system is the cross tee, an integral element that contributes not only to the structural integrity but also to the overall design and functionality of the ceiling.

- Safety Always prioritize safety during installation. Use protective gear and ensure the area is clear of any hazards.

Installation Process

The Importance of Flush Ceiling Hatches in Modern Construction

3. Drop-In Panels Typically used in modular ceiling systems, drop-in panels can be easily removed and replaced, providing quick access while ensuring a clean appearance.

1. Maintenance and Repair One of the most critical advantages of ceiling plumbing access panels is the ease of maintenance. Plumbing systems can require routine inspections, repairs, or replacements due to leaks, blockages, or other issues. Access panels allow plumbers to quickly reach these systems and perform necessary work without creating unnecessary clutter or damage to the surrounding areas.

Installation and Maintenance Considerations

The primary purpose of ceiling tie wire is to provide stability to suspended ceiling systems. In commercial construction, where ceilings may be loaded with lighting fixtures, air conditioning units, and other installations, ensuring that these elements are securely anchored is crucial. Improperly suspended ceilings can lead to catastrophic failures, posing safety risks to occupants.