splicing barbed wire

Latest articles

splicing barbed wire

...

splicing barbed wire 【splicing barbed wire】

Read Moresplicing barbed wire

...

splicing barbed wire 【splicing barbed wire】

Read MoreC, coating uniformity: galvanized layer is basically uniform with copper sulfate solution test etched five times without exposing iron.

splicing barbed wire...

splicing barbed wire 【splicing barbed wire】

Read More

splicing barbed wireThe design is designed not only for ease of installation, but also for the ability to achieve such installation in harsh terrain conditions such as cliffs, with little anchorage and little excavation for quick and easy installation. Based on the characteristics of heavy hexagonal mesh double stranded structure, even in the case of wire damage can also withstand the impact of falling rock.

...

splicing barbed wire 【splicing barbed wire】

Read MoreHexagonal cage has a wide range of applications, with the progress of science and technology, has been extended to the major hydraulic, civil engineering. Geotechnical engineering and other projects. In hydraulic hexagonal cage in river construction from closed utility, think appropriate and the use of hexagonal cage to fill stone, fixed river, can be used to avoid river erosion brought water and soil loss. In civil engineering projects, hexagonal cage that is suitable and the use of similar particle size volume particles to fill, mesh wall is formed between the cage, which is the stone cage retaining wall.

splicing barbed wire...

splicing barbed wire 【splicing barbed wire】

Read MoreWire rod to stop normalizing or soxaustenitizing treatment, large specifications with spheroidizing annealing instead. In the middle, especially before the waste product drawing process of thermal disposal throughout the selection of soxaustenitizing disposal. Decarbonization should be prevented during thermal disposal. Sulfuric acid or hydrochloric acid pickling was used to remove the oxide sheet after hot treatment. Coating (see lubrication carrier) can be dipped in lime, phosphating, borax disposal or copper plating.

splicing barbed wire...

splicing barbed wire 【splicing barbed wire】

Read Moresplicing barbed wire

...

splicing barbed wire 【splicing barbed wire】

Read More

splicing barbed wire

Post time: 09-09-22...

splicing barbed wire 【splicing barbed wire】

Read Moresplicing barbed wire

...

splicing barbed wire 【splicing barbed wire】

Read Moresplicing barbed wire

...

splicing barbed wire 【splicing barbed wire】

Read More

Popular articles

Post time: 24-08-22According to the different technology is divided into different types, you can choose according to your own needs. Has good flexibility and elasticity, the main role of annealing wire is to control its degree of softness and hardness, when the annealing wire is made of steel wire, now more used in the construction industry bundle use, compared with ordinary iron wire is also softer, has a better luster.

- Because they are afraid of rain, there is no need to say more about this, and the surface packaging is more afraid of sun, so it is not recommended to prevent outdoor exposure to sunlight, which will lead to the loss of the woven bag, resulting in the internal blade barbed wire exposed to affect the later use.

Links

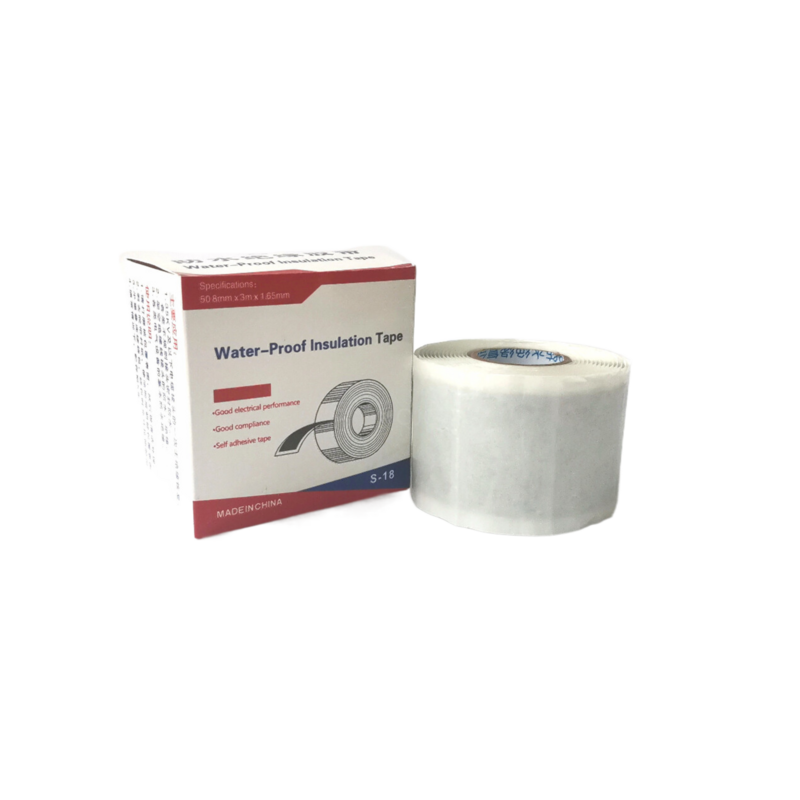

- On the other hand, green electrical tape is typically used to indicate grounding or earth connections in electrical circuits. It serves as a visual reminder that the particular wire or connection is grounded, ensuring the safety of individuals working on the circuit. Green tape is also used to insulate wires and cables, protecting them from exposure to moisture, chemicals, or heat.

- The manufacturing process of electrical tape involves several stages. It starts with the selection of raw materials, which are then processed into a thin, flexible film. This film is coated with an adhesive, followed by a process called calendaring, where the tape is passed through rollers to achieve the desired thickness and consistency. After this, the tape is wound onto rolls and undergoes quality control checks to ensure it meets industry standards for conductivity, tensile strength, and temperature resistance.

rubber seal strip. In addition, rubber seal strips can also help to reduce drafts and improve indoor air quality by preventing the entry of outdoor pollutants.

Splicing tape is an essential tool in the world of film production and editing. It is used to connect different pieces of film together seamlessly, allowing for smooth transitions between scenes and shots. Splicing tape comes in various types, each serving a specific purpose in the editing process.

varnished cambric tape uses.

Therefore, the insulation must not only have the dielectric properties we seek but the mechanical strength as well. We want insulation that is:

2. Ease of Application

self adhesive electrical tape. It comes in various colors, each signifying a different purpose. For instance, red tape is often used to indicate live wires, whereas black or white tape may be used for neutral wires, thus aiding in color-coding for easy identification during installations or repairs.

self adhesive electrical tape. It comes in various colors, each signifying a different purpose. For instance, red tape is often used to indicate live wires, whereas black or white tape may be used for neutral wires, thus aiding in color-coding for easy identification during installations or repairs.4. Environmental Resistance Beyond waterproofing and durability, butyl rubber roofing sheets resist corrosion, mildew, and biological growth. These properties contribute to maintaining the structural integrity of buildings and minimizing the need for maintenance over time.

Wrapping tape on a high voltage cable can be time consuming and error prone since the careful build-up of tape requires accurate half-lapping and constant tension in order to reduce build-in air voids. Rubber tapes are designed to stretch−some up to 1000%. Elongating the tape this way drives to compression, and that results in the strong self-fusion that provides great insulation and moisture protection.

Overall, heavy duty floor tape is a versatile tool with a wide range of applications. Its durability, strong adhesive properties, and ability to withstand heavy use make it an essential part of maintaining safety and organization in various settings. Whether you're looking to improve efficiency in your warehouse, create clear pathways in a hospital, or maintain order in a school, floor tape can help you achieve your goals.

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.